Computerized Lock Stitch Multi-needle Quilting Machine: The Masterpiece of Modern Sewing Technology

Introduction

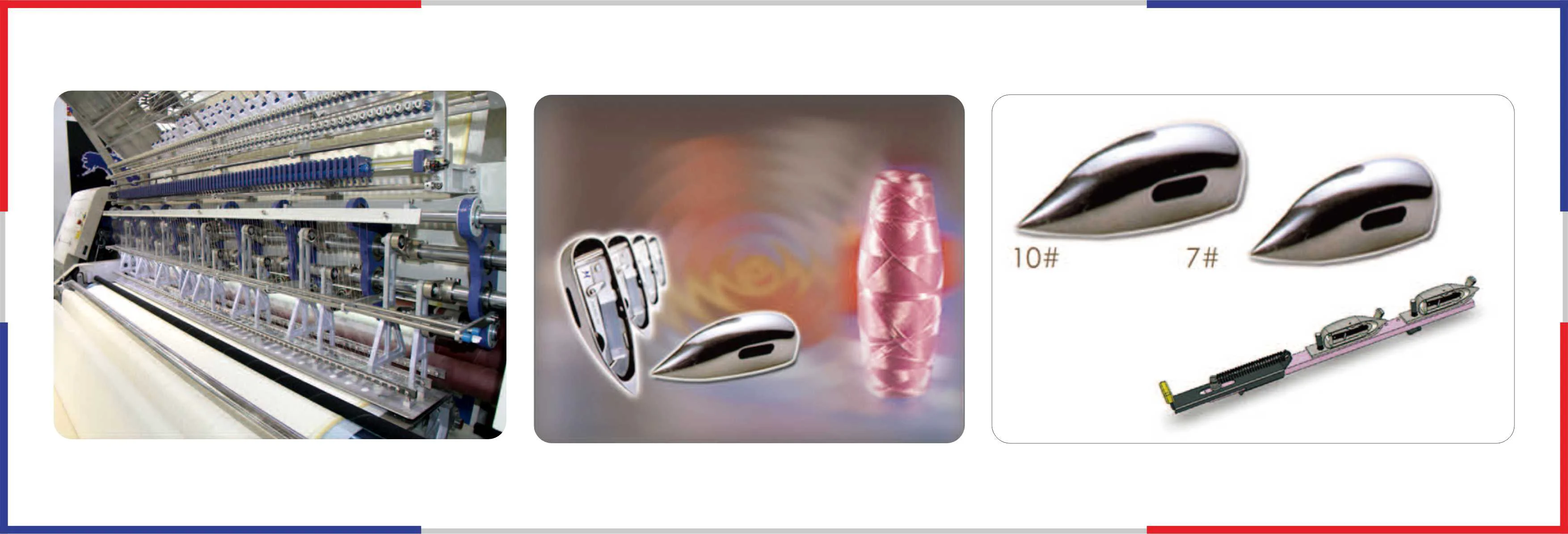

The art of quilting has stood the test of time, evolving from hand-stitched creations cradled in the loving hands of artisans to the sophisticated technology of today. Among the myriad of advancements that have transformed quilting, the Computerized Lock Stitch Multi-needle Quilting Machine stands tall at the forefront. This innovation marries traditional craftsmanship with groundbreaking technology, enabling professionals and hobbyists alike to create intricate, high-quality quilts with unparalleled efficiency.

As we delve further into this stellar machine, we explore its specifications, unique features, enhancements in productivity it offers, and its transformative impact on the quilting industry.

Specifications Overview

The Computerized Lock Stitch Multi-needle Quilting Machine is engineered with precision, ensuring optimal performance across various applications. Let’s look at the highlighted specifications:

- Dimensions (LWH): The machine is available in configurations of 3800 mm x 1320 mm x 1800 mm, 4650 mm x 1320 mm x 1830 mm, 5180 mm x 1320 mm x 1830 mm, and 5550 mm x 1320 mm x 1830 mm, allowing versatility for different workspace setups.

- Quantity of Needle Bars: The machine features two needle bars, enhancing stitching capabilities and design options.

- Quilting Width: With available widths ranging from 1600 mm to 3250 mm, the machine accommodates short and long quilting projects seamlessly.

- Space Between Needle Rows: Consistent spacing at 76.2 mm between needle rows ensures precise, uniform stitching essential for intricate designs.

- X-axis Movement Displacement: The remarkable 203.2 mm to 304.8 mm displacement enables seamless movement across the quilting surface, allowing the user to maneuver fabric with ease.

- Thickness of Quilting: Designed for quilting thickness of ≤25 mm, the machine can handle multiple fabric layers, making it ideal for thicker quilts.

- Stitch Length: Adjustable stitch lengths ranging from 2 mm to 5 mm provide flexibility in design and enhance the machine’s adaptability to different quilting styles.

- Speed of Production: Incredible production speeds of 20 to 120 meters per hour meet the demands of high-volume sewing operations, ensuring projects are completed efficiently.

- Total Power Required: The machine operates with a total power requirement of 5KW to 6KW across various models, ensuring energy efficiency while maintaining robust performance.

- Voltage: With options for 380V/50HZ or 220V/60HZ, the machine can be adapted to different electrical systems around the world.

- Gross Weight: The machine’s weight varies from 3200 KG to 5000 KG, signifying robust construction and stability during operation, providing confidence in its durability and reliability.

| Parameter | Model 1 | Model 2 | Model 3 | Model 4 |

|---|---|---|---|---|

| Size (L×W×H mm) | 3800×1320×1800 | 4650×1320×1800 | 5180×1830×1830 | 5550×1830×1830 |

| Quantity of needle bar | 2 | 2 | 2 | 2 |

| Quilting width (mm) | 1600 | 2400 | 2850 | 3250 |

| Space between needle rows (mm) | 76.2 | 76.2 | 76.2 | 76.2 |

| Space between needles (mm) | 25.4 | 25.4 | 25.4 | 25.4 |

| X-axis movement displacement (mm) | 203.2 | 304.8 | 304.8 | 304.8 |

| Thickness of quilting (mm) | ≤25 | ≤25 | ≤25 | ≤25 |

| Stitch length (mm) | 2~5 | 2~5 | 2~5 | 2~5 |

| Speed of production (m/h) | 20~120 | 20~120 | 20~120 | 20~120 |

| Model of needle | 16#, 19# | 16#, 19# | 16#, 19# | 16#, 19# |

| Speed of main shaft (RPM) | 550~750 | 550~750 | 500~750 | 450~650 |

| Total power required | 5 kW | 5 kW | 6 kW | 6 kW |

| Voltage | 380V/50Hz 220V/60Hz | 380V/50Hz 220V/60Hz | 380V/50Hz 220V/60Hz | 380V/50Hz 220V/60Hz |

| Gross weight (kg) | 3200 | 4200 | 4500 | 5000 |

Key Features

- Automatic Lock Stitch Technology: This advanced feature ensures that every stitch is secure, eliminating worries over unraveling seams. Its reliability gives quilters peace of mind when working on their masterpieces.

- Multi-needle Capability: The two-needle design is crucial, allowing for various stitching styles and design complexities. This multi-needle arrangement enhances not just creativity, but also significantly improves efficiency by executing multiple stitching lines simultaneously.

- Precision Control Panel: A user-friendly control panel with intuitive buttons and display makes operational adjustments a breeze. Users can easily switch between settings, monitor progress, and customize parameters according to their requirements, allowing for maximum control over their quilting projects.

- X-axis Movement: The smooth and precise X-axis movement allows the machine to cover both delicate and robust fabric types with ease, while the pre-programmed patterns enable users to create consistent, intricate designs without any manual adjustments.

- Durable Construction: Built to withstand the rigors of constant usage, the machine’s durable structure and high-quality components ensure longevity, reducing the need for frequent maintenance or replacement.

- Versatile Applications: Ideal for commercial use, this machine excels in quilt manufacturing, upholstery, and any fabric-based creations. Its versatility extends to both industrial and artisanal applications, catering to a range of users, from professional quilt makers to small crafting businesses.

Productivity Enhancements

The Computerized Lock Stitch Multi-needle Quilting Machine introduces revolutionary productivity improvements that make it a valuable asset in any sewing environment. With a focus on efficiency, the machine accommodates large-volume orders without sacrificing quality and provides professional finishings to each creation.

- Increased Output Speed: The ability to produce material at speeds of up to 120 meters per hour ensures that large-scale operations meet tight deadlines without compromising quality. This rapid output caters to mass production needs or just multiple projects in a shorter time.

- Reduced Labor Costs: Automation minimizes the manpower required to operate, making it an economically viable solution for businesses. By streamlining operations, businesses can potentially reduce labor costs while increasing their output capacity.

- Consistent Quality Control: Automated stitching patterns guarantee precision in each seam, thereby minimizing errors associated with hand sewing. This leads to units that are consistently accurate and have fewer discrepancies—crucial for professional-grade work.

- Ease of Use: With its automatic features, operators require less training to become proficient, and setups can be executed quickly. This user-friendliness enables more personnel to engage in production, ensuring seamless workflows.

Impact on the Quilting Industry

The Computerized Lock Stitch Multi-needle Quilting Machine is more than just a machine; it represents a paradigm shift in quilting capability. Traditionally, quilting was a labor-intensive task that required immense skill and time. Now, with this advanced machine, quilters can unleash their creativity without being hindered by the limits of manual stitching.

- Empowering Artisans and Entrepreneurs: This machine offers independent quilters the tools necessary to elevate their craft. As they create stunning quilts in less time, artisans can also expand their offerings—focusing on complex designs that would have previously required significant time investment.

- Facilitating Innovation: The technological advancements embodied in this quilting machine encourage designers to experiment and innovate. The combination of ease of use, speed, and precision allows for more experimental designs, fostering creativity across the industry.

- Sustainability and Efficiency: By producing high-quality quilts in less time, the machine also aids in moving towards sustainable practices. Efficient production processes minimize waste, making it a responsible choice for eco-conscious businesses.

Conclusion

In the realm of quilting, the Computerized Lock Stitch Multi-needle Quilting Machine is undoubtedly a game changer. Combining cutting-edge technology with user-friendly features, it revolutionizes how quilters approach their craft. Its specifications highlight durability, adaptability, and efficiency, making it indispensable for both commercial and hobbyist quilters.

The ascent of this machine symbolizes an unwavering commitment to innovation and quality in the quilting industry, promoting creativity while driving productivity. No longer confined by the constraints of traditional quilting methods, artisans can now explore their potential like never before.

Investing in the Computerized Lock Stitch Multi-needle Quilting Machine is not just a choice for efficiency; it’s a commitment to the future of quilting. As this technology redefines the boundaries of what is possible, your imagination is truly the only limit. Create, innovate, and produce with pride—this machine is here to help you stitch your dreams into reality.

Categories

Automation conneting equipment auxiliary machine Foam machinery Mattress machines Metal processing machine Plywood working machine Solid wood working machineTags