Flame Lamination Machine: Revolutionizing Composite Manufacturing

In today’s fast-paced production environment, the demand for high-quality composite materials is ever-increasing. Industries ranging from automotive to furniture rely on advanced machinery that can deliver precision, efficiency, and reliability in the lamination processes. The Flame Lamination Machine stands at the forefront of this revolution, designed to ensure superior bonding of various composite materials while optimizing productivity in manufacturing settings.

Overview

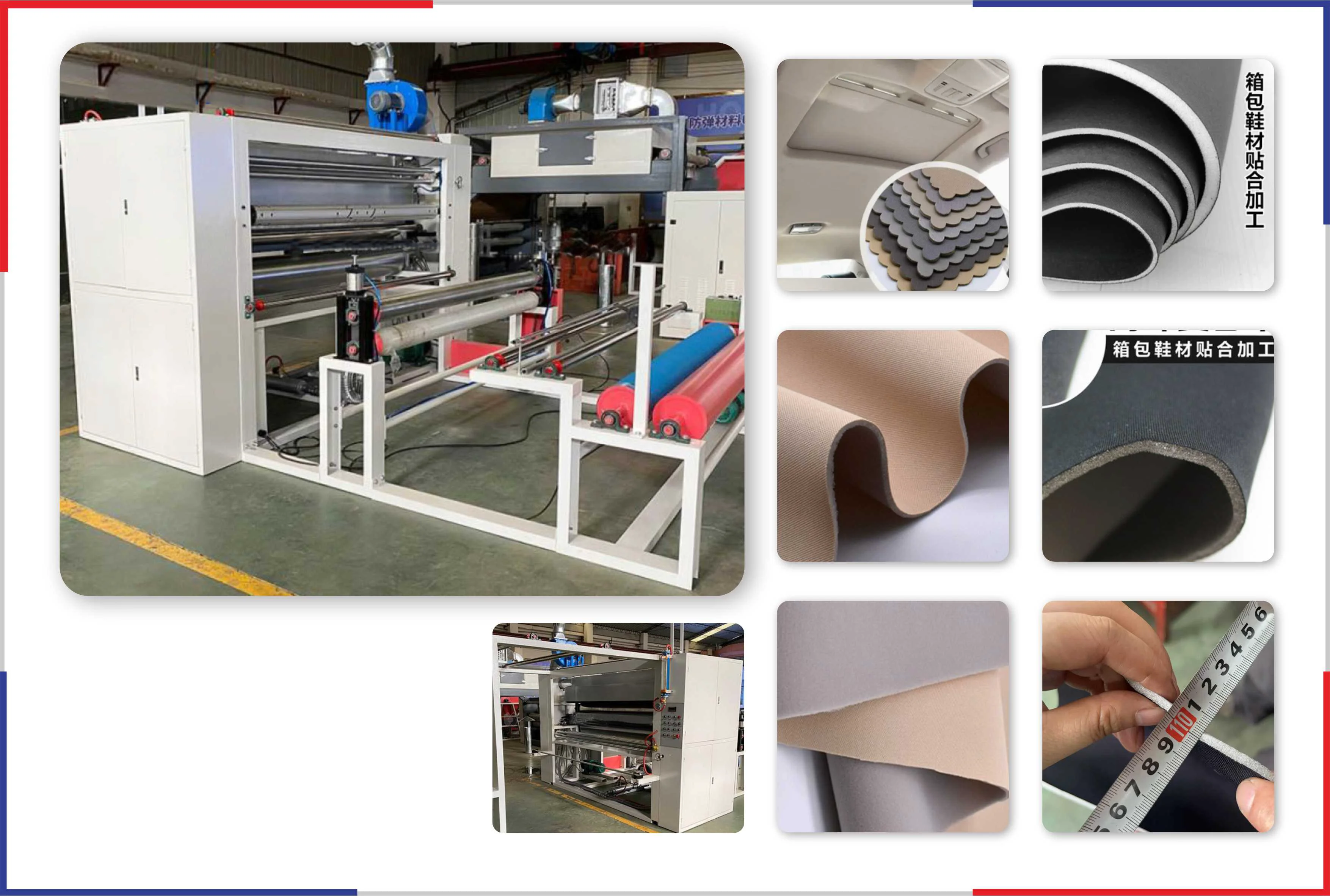

The Flame Lamination Machine is a state-of-the-art apparatus that utilizes flame technology to construct a seamless bond between diverse materials including cloth, leather, foam, and XPE composites. By applying flame to the surface of the substrates to activate the adhesive, this machine facilitates an efficient lamination process that retains the integrity and durability of the materials.

Key Features and Advantages

- Versatile Material Compatibility: This machine caters to a wide range of composite materials, providing unmatched versatility essential for industries that require various combinations of substrates. Whether you are working with soft coverings for car interiors, sophisticated upholstery for furniture, or reliable insulation materials for construction, this machine effortlessly accommodates your specific needs.

- Advanced Technology Integration: Our Flame Lamination Machine boasts advanced motor transmission technology combined with frequency conversion synchronization. This ensures smooth operation and consistent results with each cycle. The enhanced control capabilities allow operators to fine-tune parameters for optimum performance based on the specific requirements of the materials in use.

- Maximized Efficiency with High Output: With a working speed ranging from 0.5 to 40 meters per minute, the Flame Lamination Machine is designed for high-volume production runs. This speed not only boosts productivity but also helps in meeting stringent delivery timelines without compromising on the quality of lamination.

- Optimized Roller Design: Featuring a roller width of 1800mm and a maximum effective composite width of 1650mm, the machine allows for large-scale production. Additionally, the pneumatic roller pressing mode guarantees uniform pressure distribution across the lamination surface, enhancing the bonding quality.

- Cool Under Pressure: The cooling mechanism uses water (to be provided by the customer), ensuring that the materials maintain their properties post-lamination by regulating temperatures effectively. This feature mitigates the risk of warping or damage that could adversely affect the finished product.

- Durable and Robust Construction: Built with high-quality materials that ensure longevity, the Flame Lamination Machine is crafted to handle heavy-duty workloads. Its overall dimensions of 6000mm (L) x 2600mm (W) x 2600mm (H) make it a commanding presence in any production facility while also ensuring stability during operation.

- Energy Efficient Operation: Powering this robust machine with an overall power requirement of 11KW signifies its energy-efficient design. The machine operates effectively while consuming less energy than traditional lamination systems, translating to reduced operational costs and a smaller carbon footprint.

Specification Details

For those interested in diving deeper into the technical aspects, here are some specifications of the Flame Lamination Machine:

| Parameter | Specification |

|---|---|

| Power Supply | 380V 50Hz Three-Phase 220V 50Hz Two-Phase |

| Composite Materials | Cloth, leather, sponge, XPE composite materials, etc |

| Maximum effective composite width | 1650 mm |

| Roller Width | 1800 mm |

| Transmission Mode | Motor Transmission |

| Control System | Frequency Conversion Synchronization |

| Overall Power | 11 kW |

| Overall Dimension | 6000(L) × 2600(W) × 2600(H) mm |

| Cooling Mode | Water Cooling (Provided by the customer) |

| Working speed | 0.5-40 m/min |

| Roller Pressing Mode | Pneumatic |

Applications

The versatility of the Flame Lamination Machine is evident from its broad range of applications. Some notable applications include:

- Automotive Interiors: Enhancing the aesthetics and comfort of car interiors with high-quality laminated upholstery materials.

- Furniture Manufacturing: Integrating various fabrics and foams to create durable and stylish furniture products, from sofas to office chairs.

- Footwear Production: Laminating materials that deliver comfort and flexibility, essential for high-performance footwear.

- Thermal and Acoustic Insulation: Applying flame lamination technology to create composite panels that effectively insulate against temperature changes and noise.

Enhancing Your Production Capabilities

Investing in a Flame Lamination Machine not only modernizes your production line but also enhances the quality and variety of products you can offer. The seamless integration of technology with traditional lamination processes redefines manufacturing efficiency while ensuring finished products meet the highest industry standards.

Why Choose Our Flame Lamination Machine?

- Expert Support and Training: With every purchase, we provide comprehensive support and training for your team to ensure they maximize the capabilities of the machine.

- Warranty and Service: We stand by the quality of our products, offering warranties and reliable service agreements that help maintain your machine’s performance over the years.

- Custom Solutions: Our team can assist with custom modifications to accommodate specific operational requirements, ensuring that the machine aligns perfectly with your production needs.

Conclusion

Elevate your manufacturing processes with our highly efficient Flame Lamination Machine. Designed for versatility, durability, and precision, it is the ultimate solution for achieving superior composite bonding in various applications. Streamline your operations, reduce production costs, and increase output while adhering to the highest quality standards. Experience the future of lamination technology and transform your production capabilities with our Flame Lamination Machine today!

Categories

Automation conneting equipment auxiliary machine Foam machinery Mattress machines Metal processing machine Plywood working machine Solid wood working machineTags