Automatic Linear Sharpener ITE2515AB & ITE2515AC: Precision and Performance Redefined

Automatic Linear Sharpener ITE2515AB & ITE2515AC: Precision and Performance Redefined

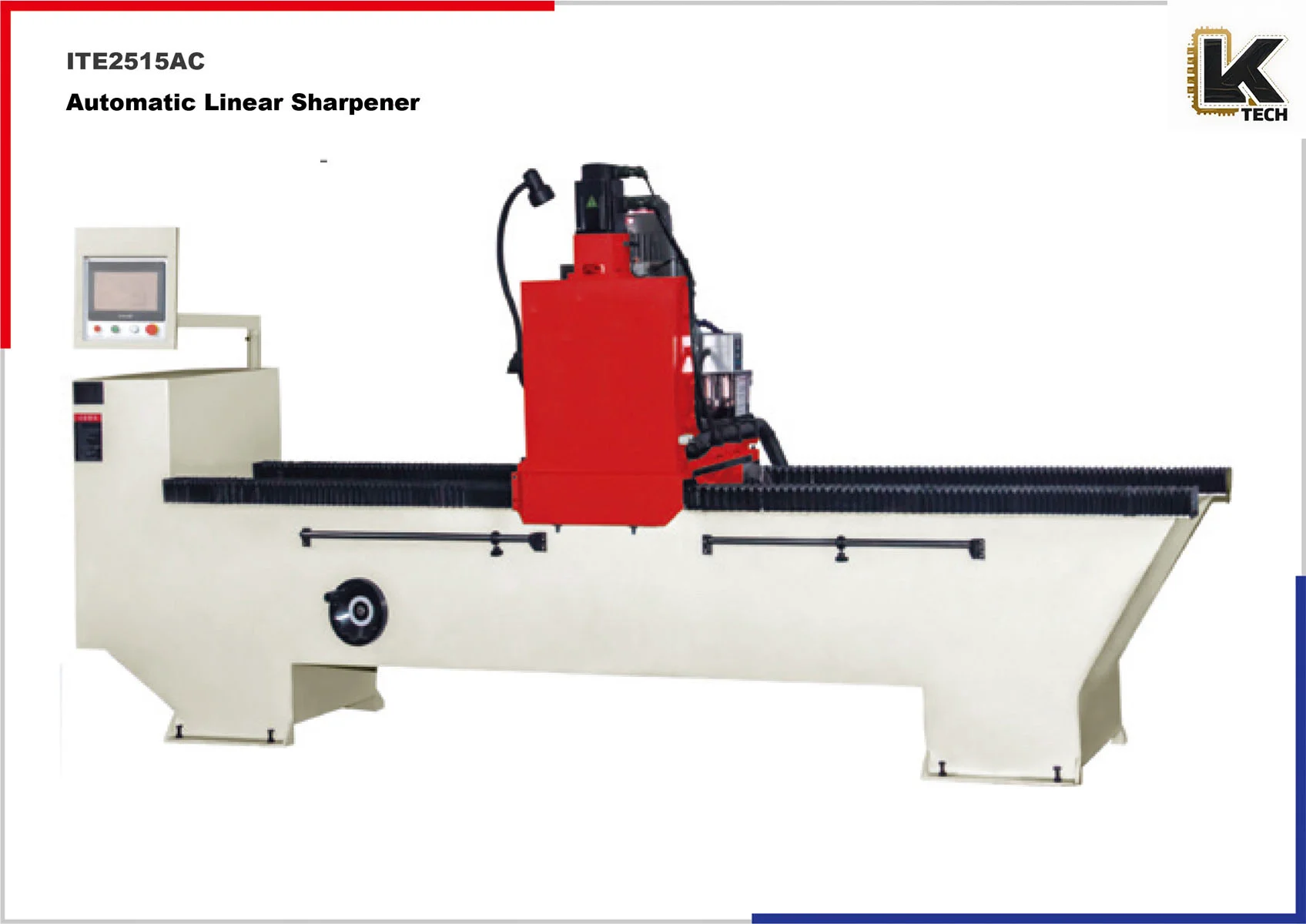

In the realm of manufacturing and industrial processes, precision tools are vital in ensuring quality outputs. One such indispensable machine is the Automatic Linear Sharpener (models ITE2515AB and ITE2515AC), renowned for its cutting-edge technology, exceptional performance, and user-friendly design. Whether you are engaged in woodworking, metalworking, or plastics processing, this sharpener is engineered to meet your sharpening needs. In this expansive product description, we will delve into the features, specifications, and benefits of these innovative sharpening machines.

1. Overview of the Automatic Linear Sharpener

The Automatic Linear Sharpener ITE2515AB and ITE2515AC are high-performance machines designed for precision sharpening of various cutting tools. Equipped with advanced automation capabilities, these models enhance productivity, resulting in consistent sharpness and precision.

2. Key Features

High Precision Components

- Imported High-Precision Ball Screw: Ensures smooth and accurate linear movement, enhancing the sharpener’s efficiency and stability. The quality components minimize friction and wear, promoting a longer lifespan for the machine.

- Electromagnetic Rotary Angle Device: This mechanism allows for variable angle adjustments, offering versatility for sharpening different types of tools. The ±90° disk rotation enables users to achieve the precise angle required for their tools.

Efficient Grinding Mechanism

- Powerful Motor System: The machines feature a high-performance main motor rated at 5.5kW, a driving motor of 0.75 kW, and a water pump powered at 90W, ensuring ample power to handle extensive sharpening operations effortlessly.

- Grinding Wheel Specifications: Equipped with grinding wheels measuring Φ145xΦ205x115mm, the machines accommodate a range of tool sizes for various applications. The wheel specifications are optimal for grinding, ensuring the highest quality finishes.

Easy-to-Use Control Interface

- User-Friendly Control Panel: Both models feature an intuitive control panel equipped with buttons and indicators for easy operation. This ensures that operators can adjust settings swiftly, an essential feature for high-paced manufacturing environments.

Variable Speed Control

- Adjustable Grinding Head Movement Speed: The grinding head can move at a variable speed range of 0 to 12m/min, regulated with frequency control. This versatility allows users to fine-tune the grinding process according to the specific tool requirements.

Robust Construction

- Solid Build Quality: These sharpeners are designed with a sturdy frame that minimizes vibrations during operation. Their durable construction ensures stability, precision, and long service life, crucial for heavy-duty industrial use.

3. Technical Specifications

Understanding the technical specifications of the ITE2515AB and ITE2515AC sharpeners can provide insights into their capabilities:

| Specification | ITE2515AB | ITE2515AC |

|---|---|---|

| Main Motor Power | 5.5 kW | 5.5 kW |

| Water Pump Power | 90 W | 90 W |

| Driving Motor Power | 750 W | 750 W |

| Grinding Wheel Specification | Φ145xΦ205x115 mm | Φ145xΦ205x115 mm |

| Effective Grinding Length | 1500 mm | 1500 mm |

| Grinding Wheel Rotate Speed | 1440 r/min | 1440 r/min |

| Electric Disk Rotation Angle | ±90° | ±90° |

| Electromagnetic Size | 190x1680 mm | 190x1680 mm |

| Grinding Head Movement Speed | 0-12 m/min (FDA) | 0-12 m/min (FDA) |

| Size | 3200x980x1700 mm | 3200x980x1700 mm |

| Weight | 1800 KG | 1800 KG |

4. Benefits of the Automatic Linear Sharpener

Unmatched Precision and Quality

The ITE2515AB and ITE2515AC ensure exceptional sharpening results, making them suitable for high-precision industries such as aerospace, automotive, and manufacturing. With their advanced sharpening technology, these machines produce finely honed edges that enhance tool performance.

Increased Productivity

Automation features significantly reduce manual intervention, leading to increased productivity. The ability to sharpen tools in a continuous manner saves valuable time and labor costs, ensuring that your production line operates smoothly.

Versatility

Both models can sharpen various tool types, including cutting, crushing, and rotary knives. This versatility makes them ideal for diversified manufacturing processes, where different tools are utilized.

Ease of Maintenance

The design of the Automatic Linear Sharpener allows for easy maintenance and servicing. Routine checks can be carried out conveniently, ensuring the machines operate at optimum performance.

Safety Features

Safety is paramount in any industrial environment. The Automatic Linear Sharpener incorporates multiple safety features, including emergency stop buttons and protective guard coverings, ensuring operator safety while enhancing productivity.

5. Applications

The Automatic Linear Sharpener is not just a tool; it’s a crucial asset across several industries, including:

- Woodworking: Used extensively to sharpen various woodworking tools such as chisels, plane blades, and saw blades, ensuring streamlined wood crafting processes.

- Metallurgy: Essential for maintaining the sharpness of cutting tools used in die and mold manufacturing, prolonging tool life and enhancing intricate designs.

- Plastic Processing: Critical in sharpening knives and blades for plastic manufacturing, facilitating cleaner cuts and improved product quality.

- Textile Industry: Used for sharpening rotary cutters and knives in fabric production, ensuring precision cutting and reducing material waste.

6. Conclusion

The Automatic Linear Sharpener ITE2515AB and ITE2515AC stand as a testament to modern engineering and design excellence. Equipped with state-of-the-art technology, these machines embody efficiency, precision, and versatility. Investing in a quality sharpener is an investment in the longevity and performance of your cutting tools, directly impacting the quality of your products and your operational efficiency.

For manufacturers seeking to enhance their sharpening processes and ensure the durability of their tools, the Automatic Linear Sharpener is an unparalleled choice that guarantees outstanding results and operational excellence. With its user-friendly design, robust construction, and high-precision components, it represents the future of tool maintenance and productivity. With a myriad of applications across various industries, this sharpener is bound to revolutionize tool management within your organization and set the standard for quality craftsmanship.

Make the smart choice today—upgrade your sharpening processes with the Automatic Linear Sharpener and reap the benefits of superior tool performance!

Categories

Automation conneting equipment auxiliary machine Foam machinery Mattress machines Metal processing machine Plywood working machine Solid wood working machineTags