Automatic Linear Sharpening Machine

Automatic Linear Sharpening Machine

Presenting the Automatic Linear Sharpening Machine – a phenomenal tool that epitomizes efficiency and precision in blade sharpening for a wide range of woodworking applications. This machine, available in various models including ITE256, ITE258A, and ITE2510A, has been engineered with state-of-the-art technology designed to meet the rigorous demands of modern workshops.

General Overview

At its core, the Automatic Linear Sharpening Machine is designed to significantly enhance productivity by automating the sharpening process, thereby reducing the time and effort traditionally required for maintaining sharp blade edges. This machine accommodates various blade sizes, making it a versatile fit for any professional environment. Whether you are in woodworking, metalworking, or any trade requiring precise blade sharpness, this machine promises exceptional results.

Features and Specifications

Model Variants

| Model | ITE256 | ITE258A | ITE2510A |

|---|---|---|---|

| Main Motor Power | 1.5 kW | 1.5 kW | 1.5 kW |

| Effective Grinding Length | 700 mm | 850 mm | 1000 mm |

| Feed Motor Power | 60 W | 60 W | 60 W |

| Grinding Cutter Adjustable | 0-90° | 0-90° | 0-90° |

| Grinding Wheel Specification | Ø32×Ø125×50mm (碗形/Calathiform) | Ø32×Ø125×50mm (碗形/Calathiform) | Ø32×Ø125×50mm (碗形/Calathiform) |

| Water Pump Motor | 40 W | 40 W | 40 W |

| Wheel Head Rotate Speed | 2800 r/min | 2800 r/min | 2800 r/min |

| Size | 1170×620×1300 mm | 1330×620×1300 mm | 1440×650×1350 mm |

All variants share the same grinding wheel specification of φ32xφ125x50mm, ensuring comprehensive compatibility with a plethora of blade styles. Each model features a water pump motor of 40W and operates at a wheel head rotation speed of 2800r/min, offering fast, consistent, and reliable sharpening.

Adjustable Features

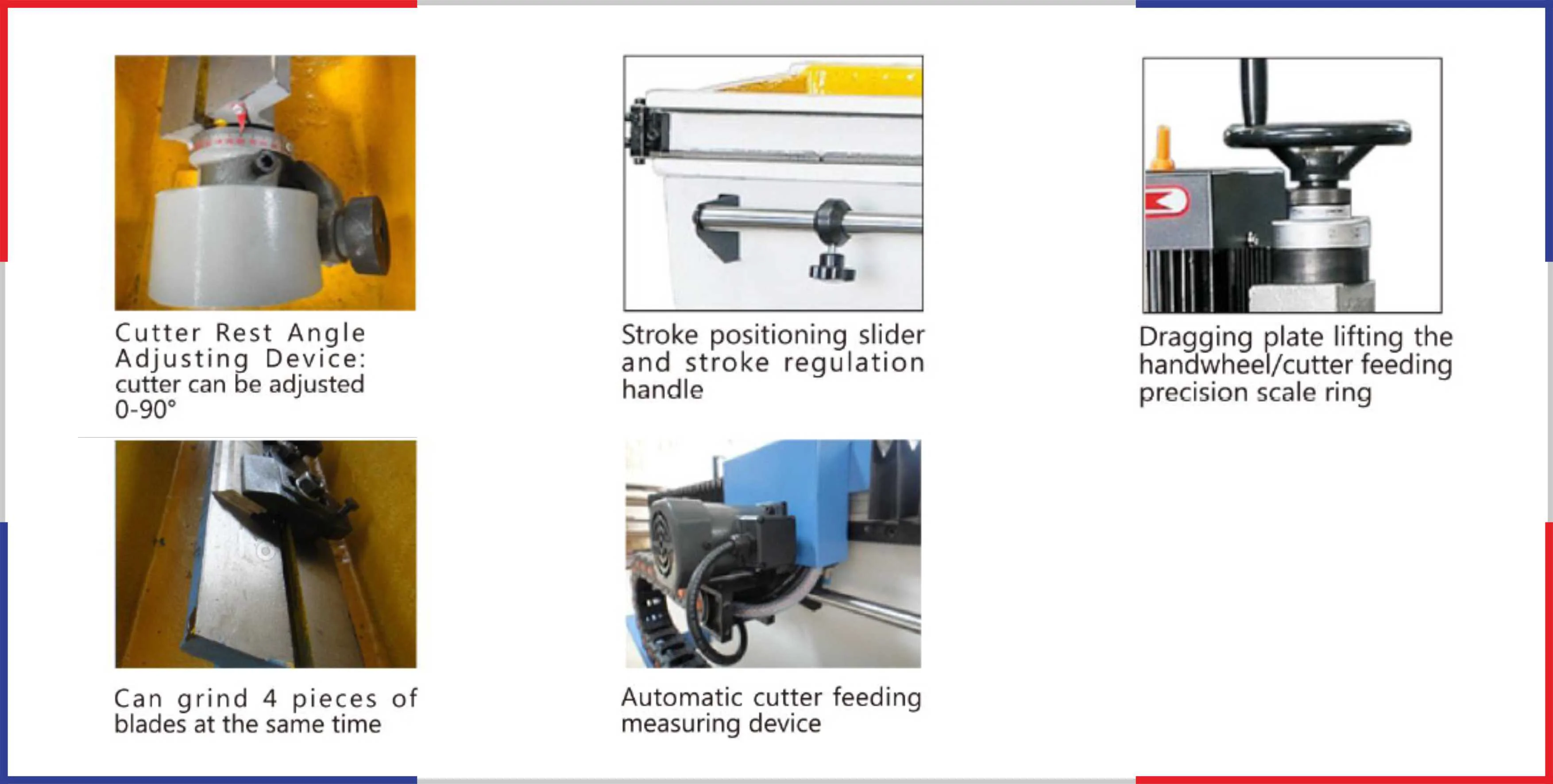

- Grinding Cutter Angle: The machine features an adjustable grinding cutter angle ranging from 0° to 90°. This adjustability ensures optimal results based on the specific blade geometry.

- Cutter Rest Angle Adjusting Device: The unique adjusting device allows for exceptional preparation—two blades can be sharpened simultaneously, increasing efficiency.

- Stroke Positioning Slider: This feature, combined with a stroke regulation handle, allows users to precisely control the movement of the blade during sharpening, ensuring consistent results and minimal waste.

User-Friendly Design

The machine’s control panel features intuitive operational switches designed for ease of use. Furthermore, the drag plate with a lifting handwheel enhances user control. The automatic cutter feeding measuring device simplifies the preparation and setup process, enabling faster engagements and reduced downtime between sharpening cycles.

High Capacity Performance

What sets the Automatic Linear Sharpening Machine apart is its ability to grind four pieces of blades simultaneously without compromising on performance. This significant capacity ensures that productivity remains high even during peak operation times. Regardless of whether you’re working with circular saw blades, planer blades, or jointer knives, the ITE series machines guarantee prompt and reliable sharpening every time.

Seamless Operation

Equipped with advanced water cooling technology, the machine effectively maintains optimal temperatures to prevent overheating during operation. This cooling system is critical for preserving the integrity of blade steel, enhancing the lifespan of both the blades and the sharpening wheel. Users can operate the machine continuously without fear of degradation from prolonged use, ultimately safeguarding your investment.

Durability and Build Quality

Constructed from high-quality materials, the Automatic Linear Sharpening Machine boasts a solid, durable build. Its well-designed structure minimizes vibration, ensuring that alignment and precision remain paramount throughout the sharpening cycle. Furthermore, the machine’s powder-coated exterior provides additional resistance to wear and environmental factors, ensuring longevity in any workshop setting.

Ideal Applications

The Automatic Linear Sharpening Machine finds a place in a variety of sectors, including but not limited to:

- Woodworking Shops: Essential for maintaining woodworking equipment such as saw blades and chisels.

- Metal Fabrication: Ideal for sharpening blades used in metal cutting and processing.

- Manufacturing Facilities: Easier maintenance for production lines utilizing sharp tools, boosting throughput and efficiency.

- Construction: Beneficial for contractors who require consistently equipped tools on job sites for sustained performance.

Conclusion

In a world where efficiency and precision are paramount, the Automatic Linear Sharpening Machine stands as a beacon of innovation and performance. With adaptable features, high capacity operation, and a user-friendly design, this machine empowers users to achieve a new standard in blade sharpening. Whether you are a small craft studio or a large-scale industrial operation, investing in the ITE series machines will undoubtedly refine your sharpened tools’ performance and durability.

Harness the power of advanced engineering and elevate your blade-maintenance routine with the Automatic Linear Sharpening Machine today! Experience unmatched quality, reliability, and productivity like never before.

Categories

Automation conneting equipment auxiliary machine Foam machinery Mattress machines Metal processing machine Plywood working machine Solid wood working machineTags