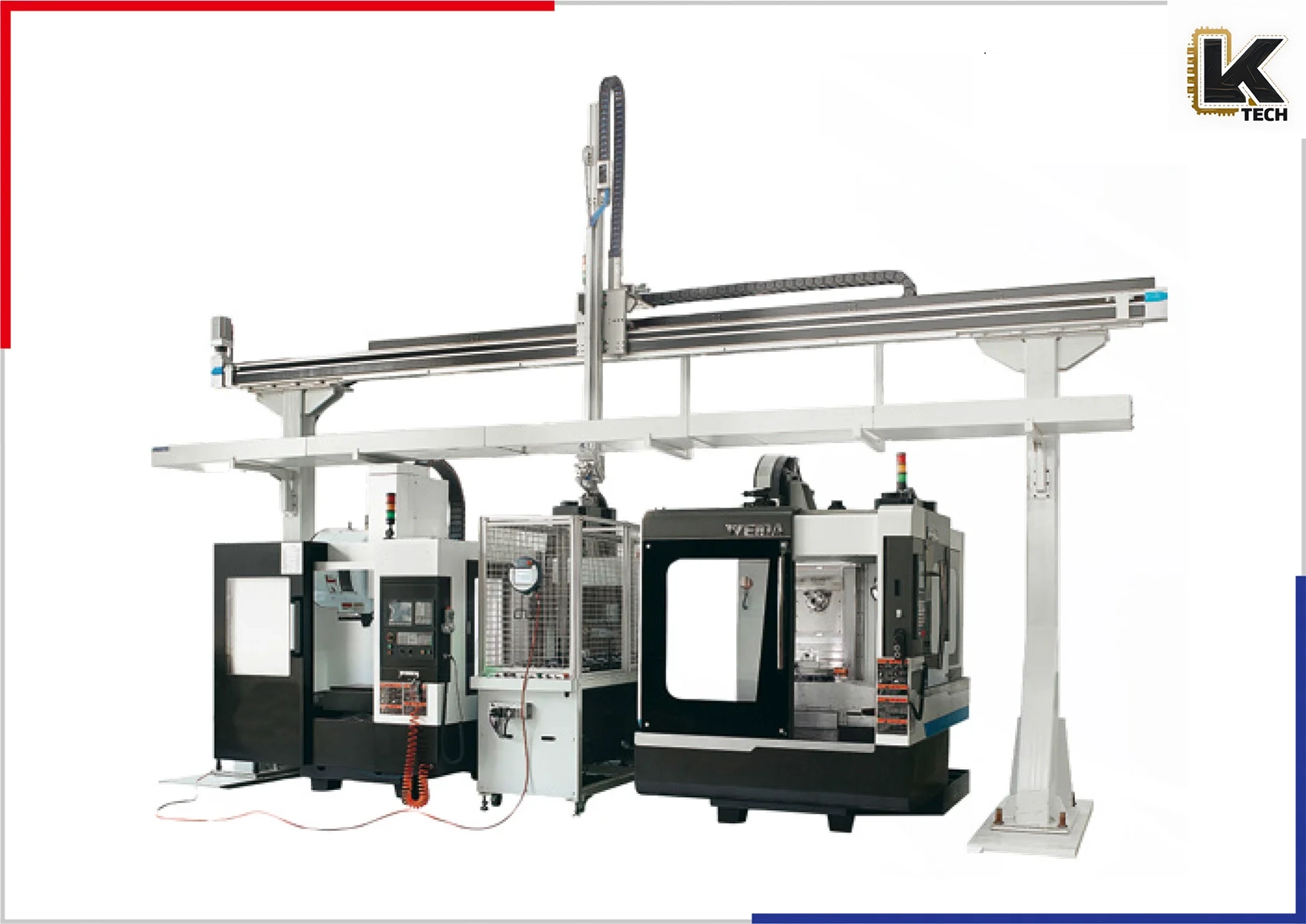

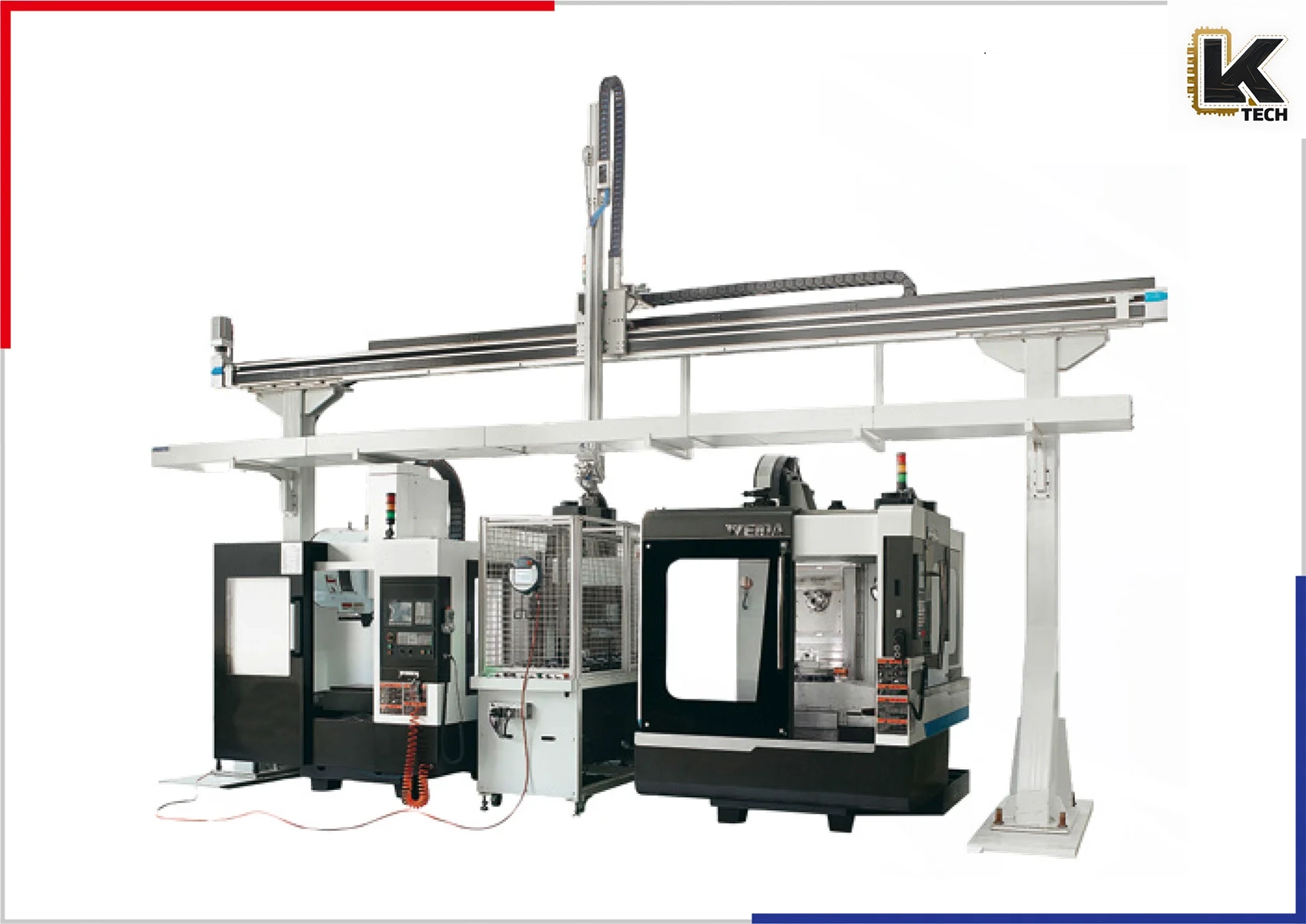

Automatic Production Line of Vertical Machining Center

Automatic Production Line of Vertical Machining Center

Introduction

In the rapidly evolving landscape of industrial automation, the demand for precise, efficient, and automated production lines is on the rise. Among these innovations, the Automatic Production Line of Vertical Machining Center stands out as a frontrunner, heralding a new era in manufacturing technology. This advanced system not only optimizes efficiency but also boosts productivity and quality, creating a seamless production environment.

Key Features

The Automatic Production Line of Vertical Machining Center is meticulously designed to cater to the needs of modern manufacturing facilities. Below are some of the noteworthy features that make this system a game-changer:

- High-Speed Performance:

- The horizontal axis (X-axis) and vertical axis (Z-axis) running speed are both rated at 120 m/min, allowing for swift operations without compromising on precision.

- Accelerated Operations:

- Equipped with an acceleration capacity of 0.5 G, the machining center can change speeds rapidly to adapt to different production needs, ensuring optimal efficiency.

- Robust Payload Capacity:

- The system can handle a grab weight of up to 10 kg, making it versatile for various machining tasks, whether it’s small intricate parts or heavier components.

- Precision Engineering:

- With a repeated positioning accuracy of the manipulator of ± 0.5 mm, the machining center guarantees consistent quality and precision across multiple operations.

- Adaptive Control System:

- The Automatic Production Line features a sophisticated control type, allowing for fixed operations that enhance reliability and accuracy in machining tasks.

- Comprehensive Power Supply Range:

- Engineered to operate in a broad power supply range of 380 ± 10% V at 50Hz, the system is compatible with standard industrial electrical grids.

- Optimal Environmental Conditions:

- Designed to function in ambient temperatures ranging from 5°C to 40°C, the system ensures reliable operation in various industrial settings.

- Air Pressure Regulation:

- The air pressure range is set between 0.4 and 0.6 Mpa, enabling controlled movements during operation that enhance precision and efficiency.

| Parameter | Specification |

|---|---|

| X Axis (Horizontal) | |

| Running speed | 120 m/min |

| Acceleration | 0.5 G |

| Z Axis (Vertical) | |

| Running speed | 120 m/min |

| Acceleration | 0.5 G |

| Grab weight | ≤10 kg |

| Repeated positioning accuracy | ≤±0.5 mm |

| Power supply | 380V±10% 50Hz |

| Air pressure | 0.4~0.6 MPa |

| Ambient temperature | 5-40 °C |

| Control type | Fixed type |

Design and Structure

The Automatic Production Line of Vertical Machining Center is built with a robust structure that promotes longevity and durability. The design integrates two vertical machining centers within a cohesive automated environment.

- Modular Configuration: The configuration is modular, allowing for easy integration into existing production lines or as a standalone system. This flexibility ensures that manufacturers can adapt the system to their unique operational needs.

- Safety Features: The system is equipped with multiple safety features, including emergency stop buttons, protective housing around the moving parts, and safety signage that protects operators and maintenance personnel.

Automated Workflow

The Automatic Production Line operates on an automated workflow that enhances productivity. The sequential operations are programmed to allow for:

- Loading and Unloading of Workpieces: The integration of manipulators for efficient loading and unloading reduces manual intervention, thereby minimizing the risk of human error.

- Seamless Transition: The transition between machining phases is automatic, providing a continuous flow of production without downtime, thereby maximizing output.

- Monitoring and Diagnostics: Equipped with advanced sensors and diagnostic tools, the system monitors its performance continually, providing data that can be used for maintenance scheduling and operational improvements.

Applications

The versatility of the Automatic Production Line of Vertical Machining Center allows it to be utilized across various industries, including but not limited to:

- Aerospace: Precision machined components are critical in aerospace applications, where even the smallest defect can have significant consequences.

- Automotive: The system excels in producing components for vehicles, from engine parts to intricate interior fittings, enhancing quality control in the high-stakes automotive industry.

- Electronics: The ability to handle small parts accurately makes this machining center ideal for the electronics industry, where precision is paramount.

- Medical Devices: The manufacturing of medical devices requires high tolerance and precision, both of which are guaranteed by this high-tech production line.

Benefits to Manufacturers

Manufacturers integrating the Automatic Production Line of Vertical Machining Center into their operations can expect numerous advantages:

- Increased Efficiency: By automating production processes, manufacturers can significantly reduce cycle times and improve overall operational efficiency.

- Cost-Effectiveness: Reduced labor costs and minimized material waste translate into greater savings for businesses, leading to increased profitability.

- Enhanced Quality Control: The consistent precision achieved through automation leads to higher quality products, reducing the incidence of errors and rework.

- Flexibility: The ability to efficiently handle various weights and dimensions allows manufacturers to diversify their product offerings, catering to a broader customer base.

- Scalability: As business needs change, the Automatic Production Line can be easily adapted or expanded, ensuring long-term viability.

Conclusion

The Automatic Production Line of Vertical Machining Center represents a significant advancement in manufacturing technology, combining speed, precision, and efficiency in one cohesive package. As industries continue to evolve, the traditional methods of manufacturing are steadily being replaced by automated systems designed to meet market demands while also prioritizing quality and reliability.

Investing in such a system not only enhances operational capabilities but also positions companies at the forefront of technological innovation, preparing them for future challenges in the ever-competitive industrial space. Adopting the Automatic Production Line of Vertical Machining Center is not just a choice; it is a strategic move toward greater productivity and success in modern manufacturing.

Categories

Automation conneting equipment auxiliary machine Foam machinery Mattress machines Metal processing machine Plywood working machine Solid wood working machineTags