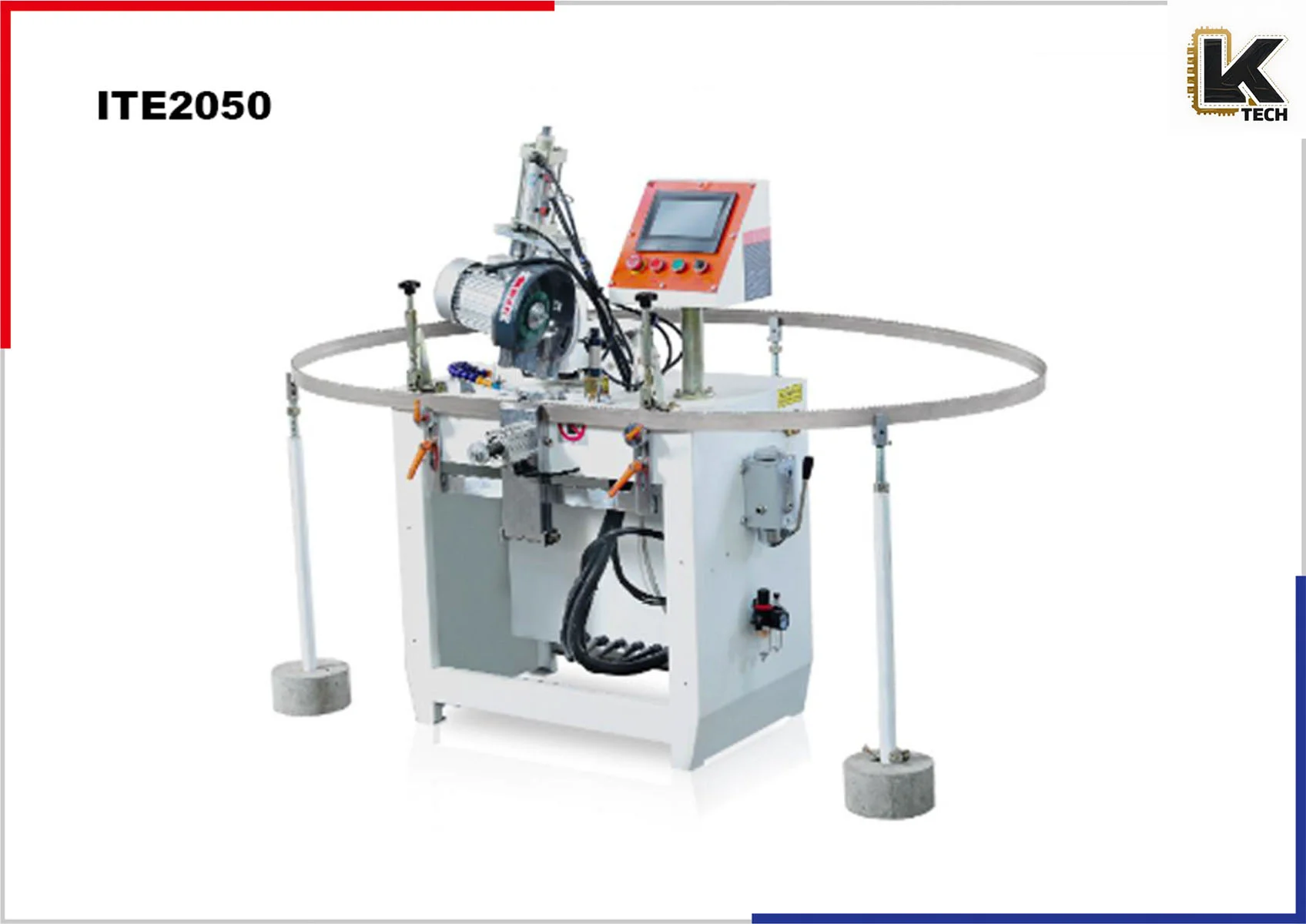

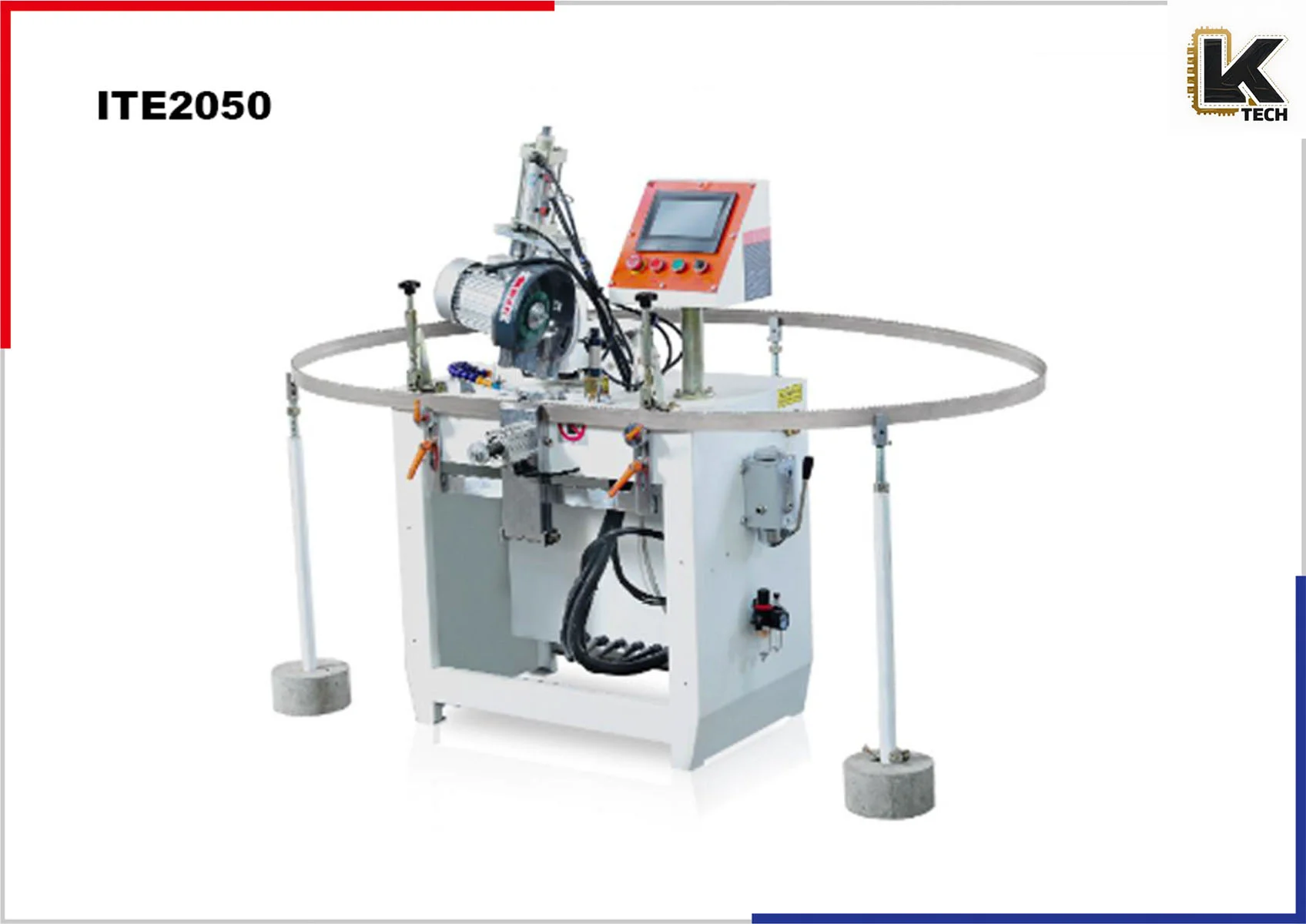

BAND SAW BLADE GRINDING MACHINE (Model ITE2050)

Introduction

Introducing the ITE2050 Band Saw Blade Grinding Machine, an innovative solution designed for precision, efficiency, and optimal performance in the realm of blade sharpening. Ideal for metal fabrication workshops, machinery manufacturers, and woodworking industries, this powerhouse machine is engineered to enhance the longevity and performance of your band saw blades, ensuring that your cutting operations are smooth, efficient, and reliable.

With its state-of-the-art technology and robust construction, the ITE2050 not only meets the rigorous standards of modern manufacturing but also elevates your operational capabilities to new heights.

Features

1. Precision Grinding Capability

The ITE2050 is capable of grinding blades with a width range of 20 to 50mm, allowing it to accommodate various blade types. Its advanced grinding range ensures remarkable precision, providing excellent results for both equal and unequal teeth configurations.

2. Adaptive Feeding Mechanics

Featuring a grinding feeding speed adjustable between 10 to 30 teeth per minute, the machine dynamically adapts to different blade types and conditions. This flexibility is crucial for varying work requirements, allowing for quicker adjustments to meet specific production demands.

3. Powerful Motor Configuration

The ITE2050 is equipped with optimized motor power settings: a 0.4kw motor dedicated to the feeding mechanism and a 0.37kw motor powering the sanding wheel. This high-performance configuration ensures stable operations, superior torque, and heightened efficiency, enabling consistently outstanding grinding results.

4. User-Friendly Operation

The ITE2050 boasts a user-friendly interface, complete with a digital display that allows operators to monitor grinding parameters such as feeding speed and grinding position effortlessly. The intuitive control panel promotes easy and precise operation, minimizing the learning curve for new users, which is particularly beneficial in fast-paced production environments.

5. Robust Construction

Built tough with a sturdy framework weighing in at 200kg, the ITE2050 guarantees stability during operation and longevity through wear and tear. The substantial weight minimizes vibrations, resulting in a smooth grinding process and ultimately contributing to enhanced blade sharpening outcomes.

6. Compact Design

With overall dimensions of 800mm (W) x 620mm (D) x 1450mm (H), the ITE2050 Boasts a compact design that optimizes shop floor space without sacrificing functionality. Its smart design makes it suitable for various workshop environments, whether in a large-scale factory or a small, independent shop.

7. Versatile Voltage Compatibility

This machine operates efficiently on a 380V supply, ensuring compatibility with industrial power systems globally. The ability to adapt to different power conditions adds to its utility, accommodating various electrical setups in workshop environments.

8. Comprehensive Safety Features

Safety is paramount in manufacturing. The ITE2050 incorporates numerous safety features, including emergency stop buttons, protective enclosures for moving parts, and clear warning signals that enhance operator safety and reduce the risk of accidents.

Specifications

| Attribute | Specification |

|---|---|

| Width of saw blade | 20-50mm |

| Grinding range | Equal/Unequal teeth |

| Grinding feeding speed | 10-30 teeth/min |

| Motor power of feeding | 0.4kw / 220V |

| Motor power of sanding wheel | 0.37kw / 50hz |

| Voltage | 380V |

| Weight | 200kg |

| Dimension | 800 x 620 x 1450mm |

Applications

The ITE2050 Band Saw Blade Grinding Machine is designed to cater to a variety of applications across different industries:

- Metalworking Shops: Sharpening band saw blades used in cutting metal alloys, steel, and other robust substances.

- Woodworking Enterprises: Perfecting band saw blades used for cutting timber, plywood, and engineered wood products.

- Manufacturing Plants: Supporting any manufacturing operations that require precision cutting tools to improve productivity.

- Tooling Companies: Ideal for workshops that specialize in the repair, maintenance, or custom fabrication of cutting tools.

Why Choose ITE2050?

- Cost-Efficiency: Regular maintenance through sharpening significantly extends the lifespan of saw blades, thus reducing overall replacement costs.

- Improved Performance: A freshly sharpened blade cuts better and faster, enhancing productivity in any operation.

- Adaptability: The ITE2050 is flexible enough to accommodate various blade sizes and types, making it a versatile addition to any workshop.

- Sustainable Operation: By sharpening existing blades instead of continually purchasing new ones, you are contributing to a more sustainable manufacturing practice.

Conclusion

In summary, the ITE2050 Band Saw Blade Grinding Machine stands out as a premier choice for professionals seeking a reliable, efficient, and robust machine for blade maintenance. With its powerful performance, extensive features, and user-friendly design, it is set to transform your cutting operations, ensuring that you achieve optimal performance and precision in every task.

For businesses invested in efficiency, cost-effectiveness, and cutting-edge technology, the ITE2050 is more than just a tool; it is an investment in the future of your operations. By ensuring your band saw blades are consistently sharpened, you guarantee top-tier cutting performance that aligns perfectly with the high standards of modern manufacturing.

Embrace the potential of the ITE2050 Band Saw Blade Grinding Machine and elevate your production capabilities to new heights. Whether you’re in metalworking, woodworking, or manufacturing, this machine is the cornerstone of maintaining your cutting tools to ensure uncompromised quality in every cut.

Categories

Automation conneting equipment auxiliary machine Foam machinery Mattress machines Metal processing machine Plywood working machine Solid wood working machineTags