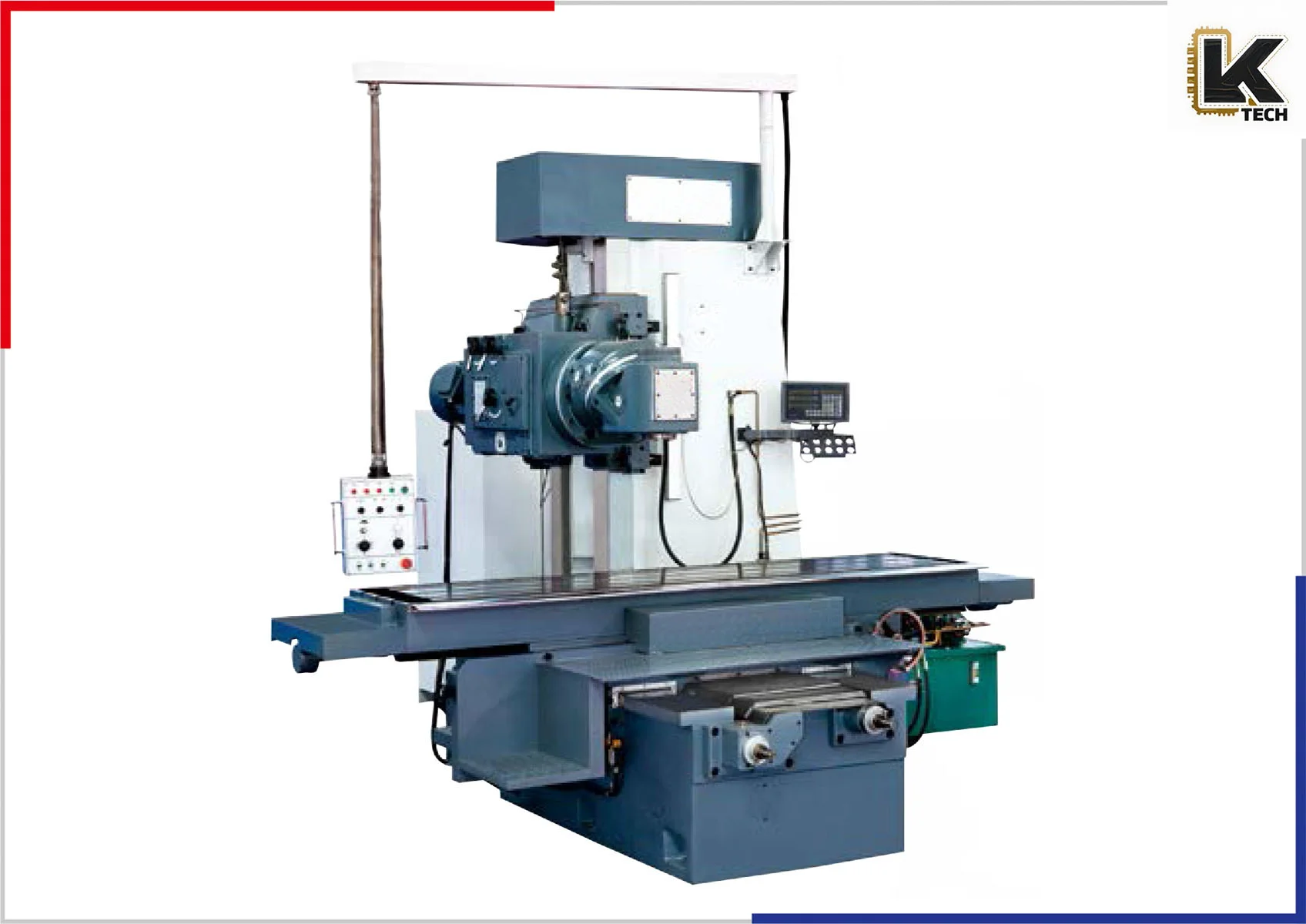

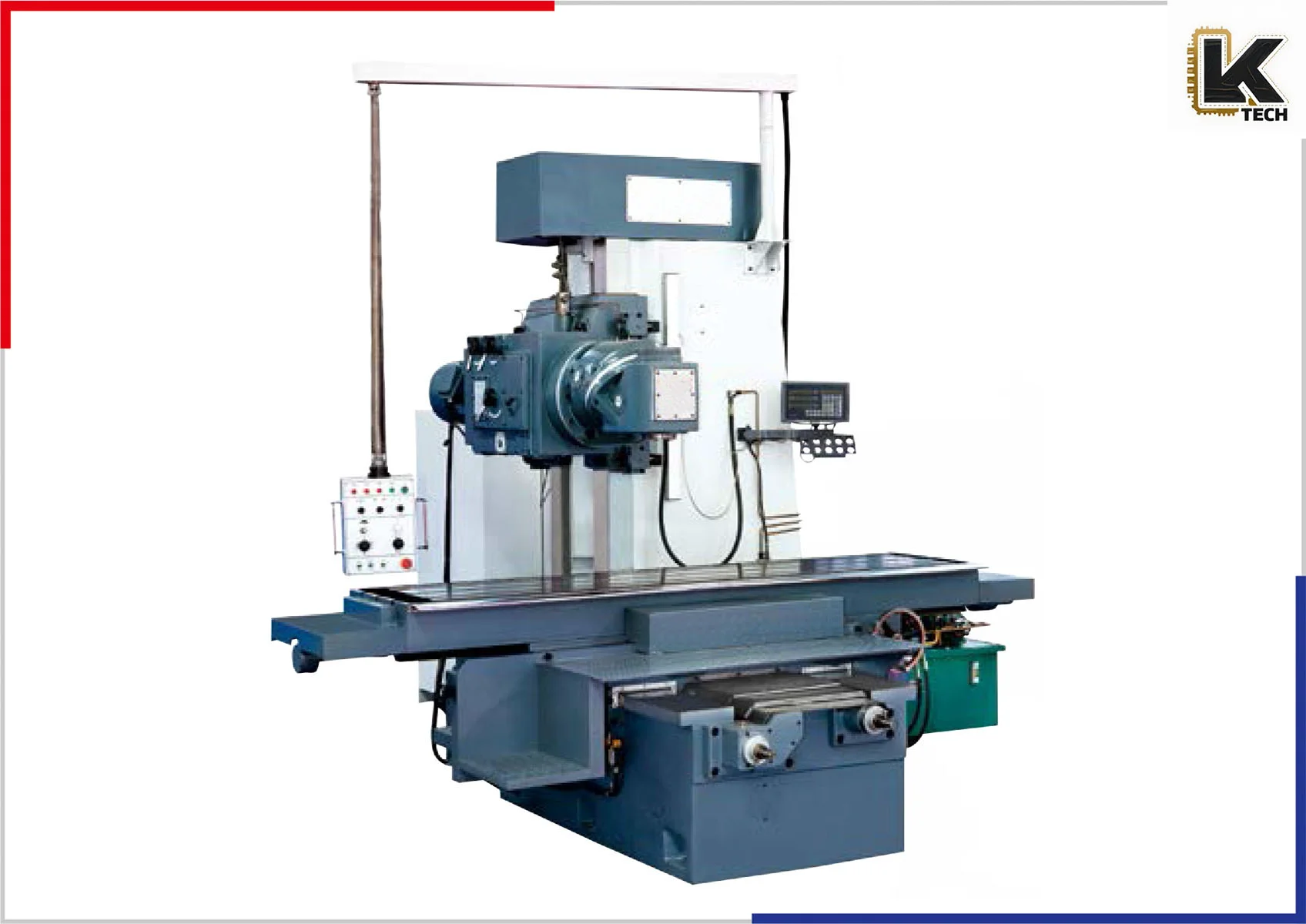

Bed-Type Milling Machine: An Indispensable Tool for Precision Engineering

Introduction

The bed-type milling machine stands as a testament to precision engineering, specifically designed to cater to complex machining tasks across various industries. It is an advanced milling solution that combines versatility and power with exceptional accuracy, making it a favored choice in workshops, manufacturing plants, and toolrooms. It is ideal for working with various materials such as metals, plastics, and composites. This comprehensive product description will explore the features, specifications, operational capabilities, and benefits of the bed-type milling machine.

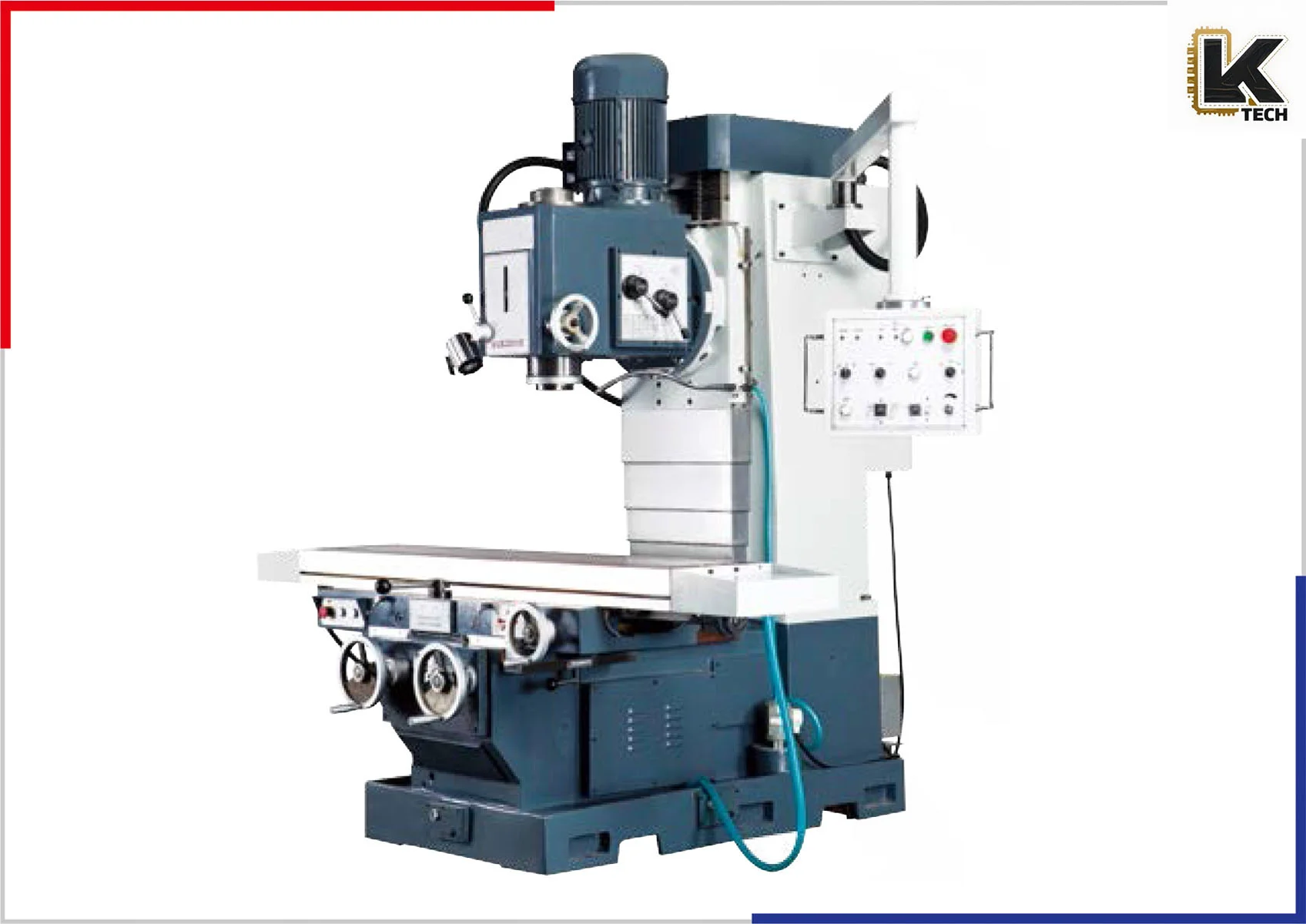

Overview of Bed-Type Milling Machine

A bed-type milling machine is distinguished by its robust design and versatility. Its setup enables users to perform a broad spectrum of operations such as milling, drilling, and boring, giving it a pivotal role in the production of intricate components. Its stable base allows for excellent rigidity during machining processes, ensuring that the workpiece remains secure and finished to exacting tolerances.

The machine typically features a horizontal spindle with the capability to accommodate varied tooling, allowing it to handle different machining scenarios efficiently. Besides, the presence of versatile axes adds to its capability, allowing for the machining of complex geometric elements and components.

Key Features

- Robust Construction:

- The bed-type milling machine is constructed from high-strength cast iron, providing excellent stability, minimizing vibrations during high-speed operations. This ensures higher accuracy and better surface finishes.

- Versatile Milling Capabilities:

- Equipped to handle multiple types of milling operations, including face milling, slab milling, and angular milling, it allows seamless adaptation between different tasks. This makes it suitable for both mass-production applications as well as one-off prototypes.

- Advanced Controls:

- Modern bed-type milling machines come with CNC capabilities, enabling automated operations and intricate designs. CNC technology also provides the ability to store programs for repeatable machining processes.

- Variable Speed Spindle:

- The milling machine can operate over a range of spindle speeds, facilitating efficient machining of various materials. With options like low, medium, and high speeds, it allows for tailored operations depending on the material properties and the type of milling being conducted.

- Precision Table Movements:

- Equipped with precision-driven servo motors, the table can facilitate smooth X, Y, and Z-axis movements. This allows for precision alignment and positioning of the workpiece for detailed milling operations.

- Swivel Head Design:

- The swivel head feature enhances flexibility, allowing for the milling of inclined surfaces or complex shapes and angles, thereby providing additional versatility to the machine.

- User-Friendly Interface:

- Most models offer intuitive control panels with digital displays, giving operators full control over parameters such as spindle speed, feed rate, and table positioning.

Technical Specifications

The following technical specifications apply to one of the models of bed-type milling machines, referred to as XA7150:

- Table Size: 2000 x 400 mm

- Table Travel (X, Y): 1500 x 550 mm

- Vertical Travel of Headstock: 100 to 650 mm

- Max Load of Table: 2000 kg

- Feed Speed Range: 20 to 2000 mm/min

- Rapid Feed Speed: Up to 3500 mm/min

- Spindle Speed Range: 66 to 1440 rpm, with 12 steps

- Spindle Motor Power: 7.5 kW

- Overall Dimensions: 3000 x 2285 x 2340 mm

- Machine Weight: 5000 kg

These specifications highlight the capabilities and robustness of the XA7150 model, making it a competent tool for industrial applications.

Additional Models & Their Specifications

- X715 Model:

- Table Size: 2100 x 500 mm

- Table Travel (X, Y): 1500 x 670 mm

- Vertical Travel of Headstock: 0 to 670 mm

- Max Load of Table: 2000 kg

- Spindle Speed Range: 35 to 1345 rpm

- Overall Dimensions: 3300 x 2380 x 2750 mm

- Machine Weight: 7300 kg

- X716 Model:

- Table Size: 2500 x 575 mm

- Table Travel (X, Y, Z): 1800 x 600 x 900 mm

- Spindle Speed Range: 40 to 1200 rpm

- Overall Dimensions: 4300 x 3200 x 3300 mm

- Machine Weight: 10000 kg

These variants further enhance the potential applications of bed-type milling machines across different production environments.

| Parameter | Units | XA7150 |

|---|---|---|

| Table size (L×W) | mm | 2000 × 400 |

| Table travel (X/Y) | mm | 1500 × 550 |

| Vertical travel of headstock | mm | 100-650 |

| T-slot (Number/Width/Distance) | mm | 3-18-100 |

| Max. table load | kg | 2000 |

| Feed speed range | mm/min | 20-2000 |

| Rapid feed speed | mm/min | 3500 |

| Spindle speed range | rpm | 66-1440 |

| Spindle speed steps | steps | 12 |

| Spindle axis to column guideway distance | mm | 600 |

| Spindle motor power | kW | 7.5 |

| Overall dimensions (L×W×H) | mm | 3000 × 2285 × 2340 |

| Machine weight | kg | 5000 |

| Specifications | Units | X715 |

|---|---|---|

| Table size | mm | 2100 × 500 |

| Table travel (X,Y) | mm | 1500 × 670 |

| Vertical travel of headstock | mm | 0–670 |

| Number/Width/Distance of T–slot | mm | 4–20–100 |

| Max. load of table | kg | 2000 |

| Feed speed range | mm/min | 10–900 |

| Rapid feed speed | mm/min | 1750 |

| Spindle speed range | rpm | 35–1345 |

| Spindle speed step | 级 (steps) | 12 |

| Distance from spindle axis to column guideway | mm | 610 |

| Spindle motor power | kW | 7.5 |

| Overall dimension | mm | 3300 × 2380 × 2750 |

| Machine weight | kg | 7300 |

| Specifications | Units | X716 |

|---|---|---|

| Table size | mm | 2500 × 575 |

| Table travel (X,Y,Z) | mm | 1800 × 600 × 900 |

| Min. distance from hor. spindle axis to worktable surface | mm | 30 |

| Min. distance from vertical spindle nose to worktable surface | mm | 49 |

| Distance from vertical spindle axis to column guideway | mm | 110 |

| Spindle speed range/steps | rpm | 40–1200 /12 |

| Number/Width/Distance of T-slot | mm | 3–22–152 |

| Spindle taper | ISO50 | |

| Longitudinal, transverse feed speed range | mm/min | 20–2200 |

| Rapid feed speed (X,Y) | mm/min | 3000 |

| Feed speed range | mm/min | 12–1320 |

| Rapid feed speed (Z) | mm/min | 1800 |

| Spindle motor power | kW | 11 |

| Max. load of worktable | kg | 3000 |

| Overall dimension (L × W × H) | mm | 4300 × 3200 × 3300 |

| Machine weight | kg | 10000 |

Benefits of Using Bed-Type Milling Machines

- High Precision:

- The design and construction of bed-type milling machines are aimed at enhancing precision during machining. The rigidity of the machine, coupled with advanced controls, allows for intricate designs to be executed accurately.

- Increased Productivity:

- The automation possibilities reduce manual intervention and increase productivity significantly. Fast feed rates and spindle speeds contribute to shorter cycle times and greater output.

- Flexibility:

- With CNC capabilities, bed-type milling machines can execute a variety of milling operations without needing extensive setup changes. This flexibility makes them an ideal choice for shops that need to react to changing job requirements or components.

- Durability:

- Built to handle tough operating conditions, bed-type milling machines feature long-lasting components that can withstand high temperatures and wear, leading to fewer breakdowns and lower overall maintenance costs.

- Ease of Operation:

- Thanking to user-friendly interfaces and digital outputs, operators with varying levels of experience can effectively manage complex operations with relative ease.

- Support for Complex Machining:

- The ability to operate multiple axes and the option for swivel heads enable the milling of complex shapes and detailed components that are increasingly demanded in modern engineering.

Applications Across Industries

Bed-type milling machines find widespread application in various industries due to their reliability and versatility:

- Automotive Industry: Used for manufacturing engine blocks, camshafts, and other intricate automotive components.

- Aerospace: Provides the precision needed for creating parts that require high reliability and accuracy.

- Tool Making: Essential for creating tools and dies with intricate designs.

- Construction: Equipment for crafting components used in construction machinery and infrastructure.

- Electronics: Applied in the production of detailed circuit boards and components.

Conclusion

In conclusion, bed-type milling machines are an essential piece of equipment for achieving high precision and efficiency in machining operations. Their robust construction, advanced features, and flexibility make them perfect for various industrial applications. Whether you’re dealing with large-scale production or intricate custom parts, investing in a bed-type milling machine will undoubtedly enhance your manufacturing processes, ensuring that you meet both quality benchmarks and production goals efficiently. The technological advancements and consistent performance of these machines reflect their status as a cornerstone in modern manufacturing.

Categories

Automation conneting equipment auxiliary machine Foam machinery Mattress machines Metal processing machine Plywood working machine Solid wood working machineTags