The Future of Precision Engineering

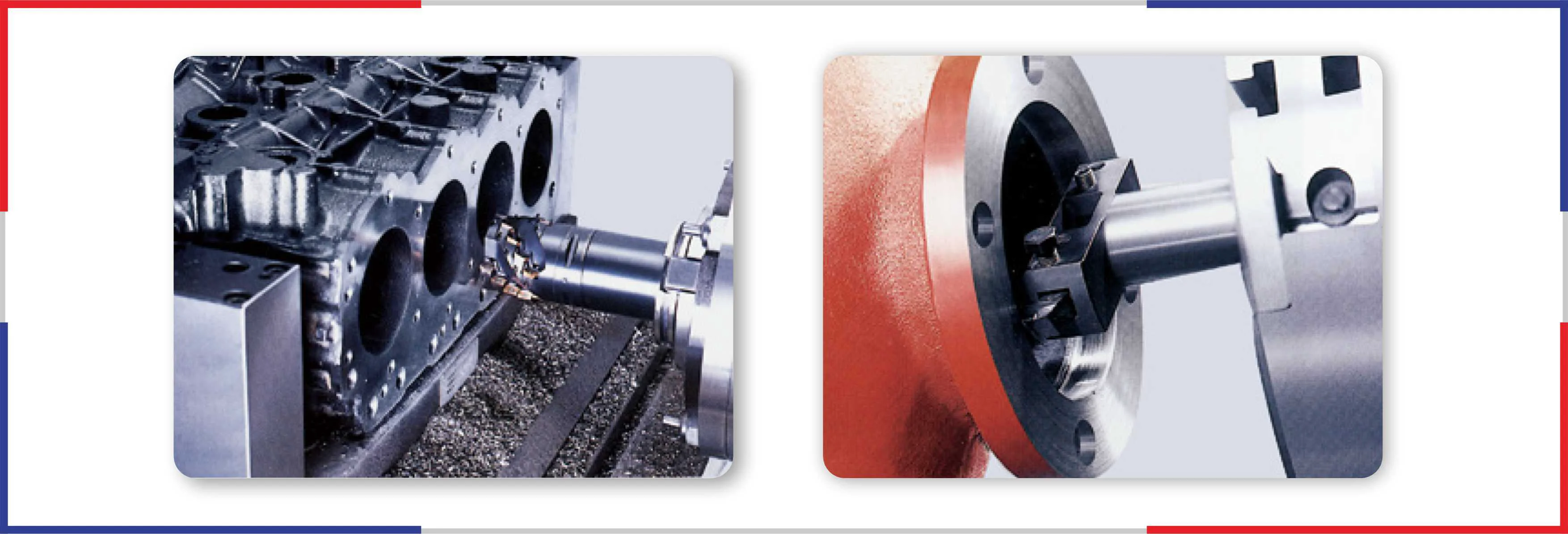

In the realm of modern manufacturing, the demand for precision and versatility in machining processes has never been higher. Businesses are seeking equipment that not only meets their machining needs but also enhances productivity and reduces operational costs. Introducing the CNC Boring and Milling Machine, a state-of-the-art solution designed for the most discerning engineers and manufacturers. This machine is engineered to meet the heaviest demands across a variety of industrial applications, from automotive components to aerospace assemblies.

Design and Build Quality

The CNC Boring and Milling Machine boasts a robust construction that prioritizes rigidity and stability during operation. Its well-designed framework keeps vibrations to a minimum, ensuring high precision in both boring and milling operations. The compact yet powerful design enables seamless integration into most workshop environments.

Built from high-quality materials, this machine is resistant to wear and tear, promising longevity and reliability even under the most demanding conditions. The streamlined aesthetic not only enhances its appeal but also promotes ease of use—all controls and functionalities are positioned intuitively for the operator’s convenience.

Exceptional Performance Specifications

| Specification (Unit) | TPK611C |

|---|---|

| Spindle Specifications | |

| Spindle diameter (mm) | ♦110 |

| Spindle taper | BT50 |

| Max. boring diameter (mm) | ♦240 |

| Max. drilling diameter (mm) | ♦50 |

| Max. allowable torque on spindle (N·m) | 1100 |

| Spindle speed range (rpm) | 12-1100 |

| Spindle motor power (kW) | 11/15 |

| Travel Specifications | |

| Z-axis (Longitudinal) (mm) | 1350 |

| X-axis (Transverse) (mm) | 1250 |

| Y-axis (Vertical) (mm) | 900 |

| W-axis (Axial) (mm) | 550 |

| Table Specifications | |

| Table size (mm) | 1320×1010 |

| Max. table load (kg) | 2500 |

| Spindle nose to table surface (mm) | 5-905 |

| Feed & Speed | |

| Feeding range (mm/min) | 0.2-330 |

| Rapid feed speed (X/Y/Z) (mm/min) | 5000 |

| Feed speed range (mm/min) | 0.5-1000 |

| Facing head speed range (rpm) | 4-130 |

| Max. machining diameter of facing head (mm) | 630 |

| Accuracy | |

| Positioning accuracy (mm) | 0.02/500 |

| Repeat positioning accuracy (mm) | 0.014/500 |

| Physical Dimensions | |

| Overall dimension (mm) | 5375×2995×3035 |

| Machine weight (kg) | 12300 |

Spindle and Travel Mechanisms

At the heart of the CNC Boring and Milling Machine is a powerful spindle with a diameter of 110 mm, guaranteeing immense torque and facilitating a wide range of tooling options. The machine features an impressive Z-axis longitudinal travel of 1350 mm, allowing operators to work on larger components without the need for repositioning. Complementing this is the X-axis transverse travel of 1250 mm and Y-axis vertical travel of 900 mm, giving a total effective range for complex machining projects.

Furthermore, the machine is engineered with a W-axis axial travel of 550 mm, making it perfect for operations requiring the facement of large workpieces or when high precision is needed in multiple dimensions.

Boring and Milling Capabilities

This machine excels in boring and milling applications, supporting a maximum boring diameter of 240 mm and a drilling diameter of 50 mm. The maximum allowable torque on the spindle measures 1100 N.m, ensuring efficient material removal even with hard metals.

In addition, the spindle motor power of 11/15 kW provides the necessary energy to achieve high cutting speeds and large material removal rates. The spindle speed can vary significantly from 12 to 1100 RPM, allowing for adaptability to different materials and precision requirements.

Table and Load Capacity

With a generous table size of 1320 x 1010 mm, the CNC Boring and Milling Machine is well-suited to handle a wide array of workpieces. The machine also boasts a maximum table load capacity of 2500 kg, which means even the heaviest workpieces can be managed effectively without risk.

The precise distance from spindle nose to table surface measures between 5 mm and 905 mm, adding flexibility for extensive machining tasks and promoting ergonomic working conditions.

Feed and Speed Control

One of the remarkable features of this machine is its vast feeding range of 0.2 mm/min to 330 mm/min and a rapid feed speed of 5000 mm/min across the X, Y, and Z axes. This combination affords rapid positioning without sacrificing accuracy. The feed speed range extends from 0.5 mm/min to 1000 mm/min, ensuring that each machining process is optimized for the material being worked on.

Operators can rest assured that the machine will maintain tight tolerances, with a positioning accuracy of just 0.02 mm and a repeat positioning accuracy of 0.014 mm, perfect for intricate engineering tasks.

User-Friendly Interface

The CNC Boring and Milling Machine is equipped with a high-tech control interface, enabling operators to program complex machining tasks effortlessly. The interface allows for quick adjustments to settings, real-time monitoring of operations, and easy input of dimensions based on specific job requirements.

Seamless integration into existing CAD/CAM systems makes this machine an excellent choice for companies that prioritize efficiency and precision.

Versatility and Applications

This CNC Boring and Milling Machine is incredibly versatile, with applications extending across various industries. It is suitable for:

- Automotive Manufacturing: Machining engine blocks, structural components, and other heavy-duty parts.

- Aerospace Engineering: Creating components that require exceptional precision and material integrity.

- Marine Engineering: Fabricating parts for shipbuilding and maintenance, often dealing with larger dimensions and tougher materials.

- Heavy Industry: Working on large components that are integral to manufacturing machinery and equipment.

Whether used for high-volume production or bespoke engineering applications, this machine meets the rigorous demands of modern manufacturing environments.

Safety Features

Safety is paramount in any industrial setting, and the CNC Boring and Milling Machine incorporates numerous features to ensure operator safety. Emergency stop buttons are easily accessible, and the machine is equipped with protective covers and shields to minimize the risk of accidents. Moreover, the integrated control system includes diagnostic capabilities that provide alerts in case of malfunctioning or irregular operation, ensuring that preventative measures can be taken swiftly to maintain a safe work environment.

Conclusion: Invest in Excellence

As industries evolve, businesses must equip themselves with the right tools to remain competitive. The CNC Boring and Milling Machine emerges as an indispensable asset, embodying precision, power, and versatility. It is designed for those who demand the best in manufacturing solutions and is backed by comprehensive support from installation to after-sale services.

With its superior specifications and unparalleled performance capabilities, this machine is ready to take your operations to the next level. By investing in this elite CNC Boring and Milling Machine, you are not just purchasing a piece of equipment; you are investing in the future of your manufacturing success.

Elevate your machining processes, enhance precision, and ensure superior quality with the CNC Boring and Milling Machine – the final piece in your industrial solution puzzle.

Categories

Automation conneting equipment auxiliary machine Foam machinery Mattress machines Metal processing machine Plywood working machine Solid wood working machineTags