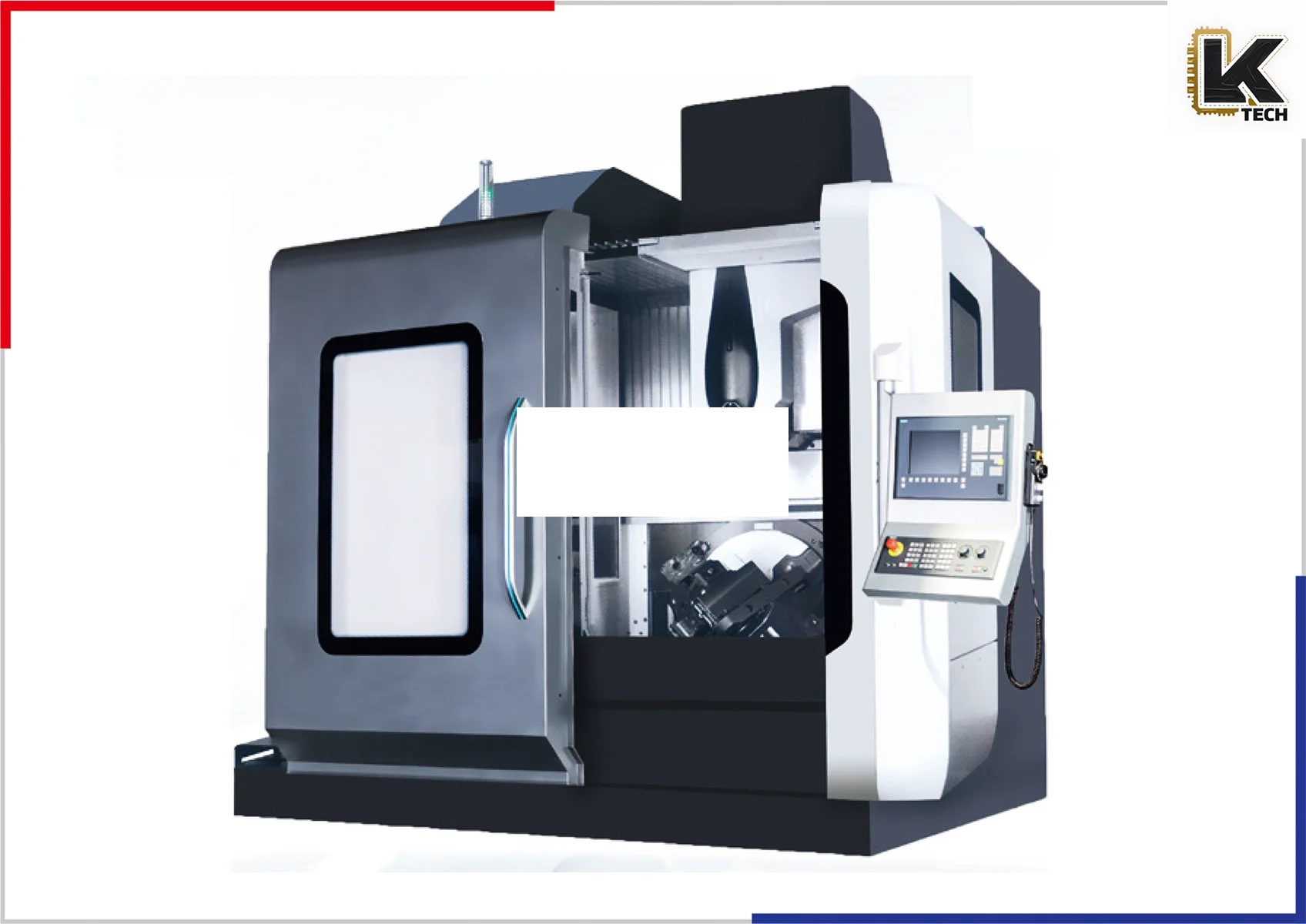

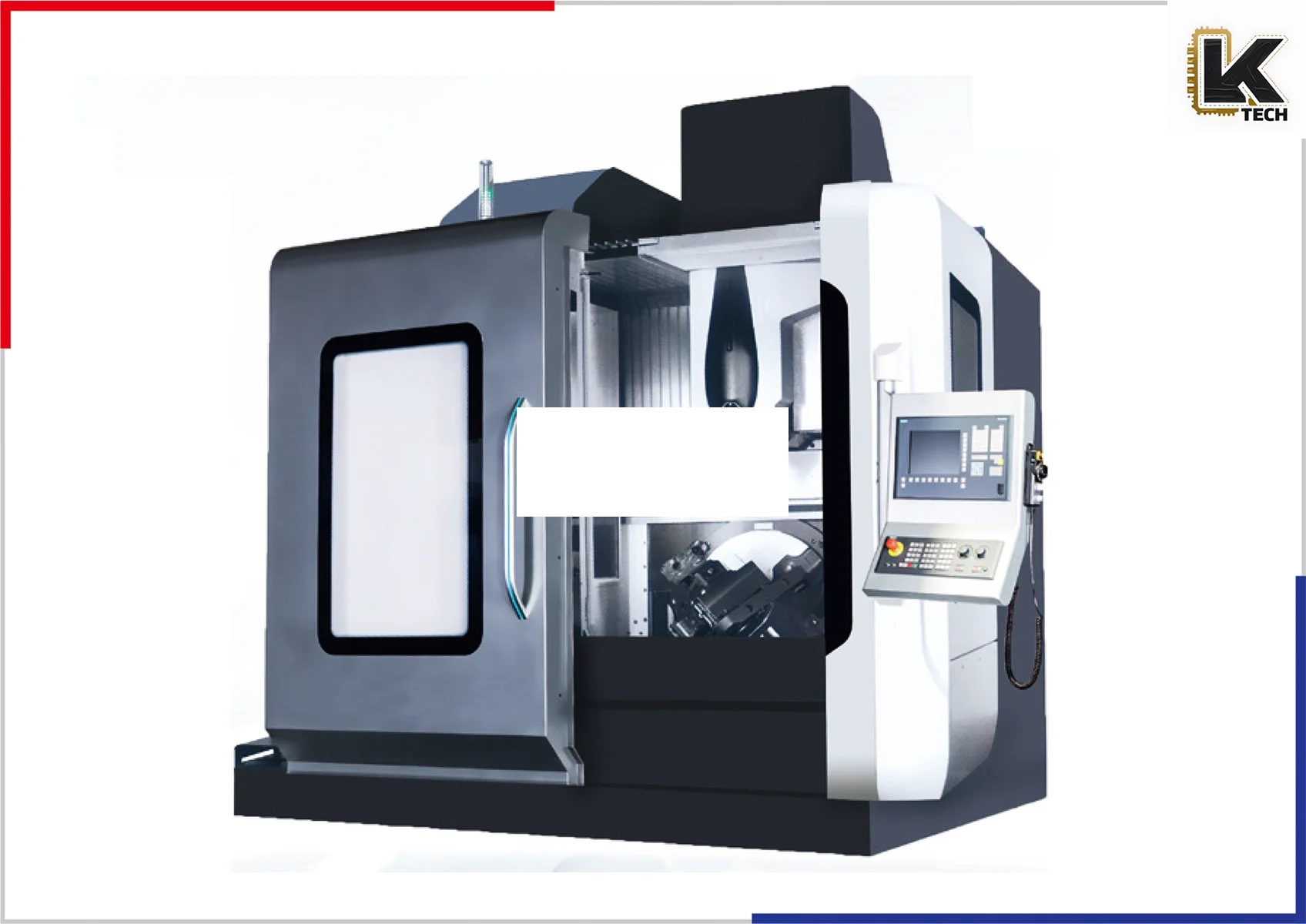

CMC650U Five-Axis Linkage Vertical Machining Center

Overview

The CMC650U is a state-of-the-art five-axis linkage vertical machining center designed for high precision and efficiency in the metal machining industry. This advanced machine combines unparalleled performance with user-friendly features, making it an essential tool for manufacturers aiming to streamline their operations and maintain a competitive edge. Ideal for complex part manufacturing, the CMC650U offers innovative technology and robustness, paving the way for a new era of machining excellence.

Key Features

-

Advanced Five-Axis Machining

The CMC650U boasts a five-axis linkage system that enables simultaneous motion on multiple axes, allowing for intricate machining capabilities. This feature is critical for producing parts with complex geometries, ensuring that tasks such as contouring, drilling, and milling can be performed with remarkable accuracy.

-

Large Table Size

With a table size of 650 mm in diameter and a T-slot size of 50 mm, the CMC650U provides ample space for larger workpieces. The generous dimensions facilitate the machining of items such as automotive and aerospace components, which often require extensive tooling and handling.

-

Exceptional Travel Capacities

The machine boasts an impressive X-axis travel of 650 mm, Y-axis travel of 520 mm, and Z-axis travel of 475 mm. This allows it to accommodate diverse workpieces, enabling the machining of various components without needing constant tool changes.

-

Rotational Versatility

The A-axis rotation range extends to ±120 degrees, while the C-axis rotation covers 360 degrees. This rotational capability allows the CMC650U to achieve more dynamic cuts and shapes, offering geometric flexibility that traditional machining centers cannot provide.

-

High-Speed Spindle

With a maximum spindle speed of 12,000 RPM and a spindle motor power of 7.5 kW, the CMC650U delivers high-speed operations, reducing cycle times and enhancing productivity. The spindle design contributes to effective heat dissipation and enhanced longevity, ensuring consistent performance during extended operating periods.

-

Robust Tool Magazine

Equipped with an arm-type tool magazine, the CMC650U can store up to 24 tools. This feature significantly reduces downtime, allowing for rapid tool changes (with a tool change time of just 1.55 seconds) and fast, efficient operations.

-

Precise Positioning and Accuracy

The machine ensures exceptional positioning accuracy with an impressive ±0.005 mm for the X/Y/Z axes and ±0.003 mm for the A/C axes. This precision is vital for applications that demand high tolerances, such as aerospace and medical component manufacturing.

-

Sustainable Design and Safety Features

The CMC650U incorporates environmentally friendly design elements aimed at reducing the ecological footprint of manufacturing processes. Moreover, the machine is equipped with safety features, including an accessible control panel for easy operation and safety mechanisms to protect both operators and the machinery.

| Specification (Unit) | CMC650u |

|---|---|

| Table Specifications | |

| Table size (mm) | ♦650×540 |

| T-slot size (mm) | 14 |

| T-slot diameter (mm) | ♦50 |

| Max. table load (kg) | 300 |

| Axis Specifications | |

| X-axis travel (mm) | 650 |

| Y-axis travel (mm) | 520 |

| Z-axis travel (mm) | 475 |

| A-axis rotation range (°) | ±120 |

| C-axis rotation range (°) | 360 |

| Spindle Specifications | |

| Spindle nose to table surface (mm) | 150-625 |

| Spindle taper | BBT40 |

| Max. spindle speed (rpm) | 12000 |

| Spindle motor power (kW) | 7.5 |

| Max. torque of spindle (N·m) | 45 |

| Tool Changer | |

| Tool magazine type | Arm type |

| Tool magazine capacity (pcs) | 24 |

| Max. tool diameter (full/empty) (mm) | ♦78/♦150 |

| Max. tool length (mm) | 300 |

| Max. tool weight (kg) | 8 |

| Tool change time (T-T) (s) | 1.55 |

| Feed & Speed | |

| Rapid feed speed (X/Y/Z) (mm/min) | 42000/42000/42000 |

| Cutting feed speed (X/Y/Z) (mm/min) | 1-10000/1-10000/1-10000 |

| Accuracy | |

| Positioning accuracy (X/Y/Z) (mm) | ±0.005/300 JIS |

| Positioning accuracy (A/C) (arcsec) | ±5 |

| Repeat positioning accuracy (X/Y/Z) (mm) | ±0.003 JIS |

| Repeat positioning accuracy (A/C) (arcsec) | 4 |

| Physical Dimensions | |

| Machine weight (kg) | 8500 |

| Machine overall size (mm) | 3970×3210×2800 |

Applications

The CMC650U is versatile and can be used across various industries, including:

- Aerospace

- Ideal for producing intricate components with high tolerances, the CMC650U is perfect for parts such as turbine blades, brackets, and housing.

- Automotive

- The machining center operates efficiently to manufacture complex engine parts, body components, and prototypes with high precision.

- Medical Device Manufacturing

- The precision of the CMC650U allows for the creation of intricate surgical instruments, implants, and various medical hardware.

- Mold and Die Making

- This machine supports the manufacturing of high-quality molds and dies used in various industries, ensuring accuracy in medium-sized production runs.

Benefits

- Boosted Productivity The CMC650U doubles as a fast-paced solution, producing parts more rapidly than traditional methods while maintaining superior accuracy.

- Reduced Labor Costs With automated features and less need for manual intervention, companies can reduce labor costs while increasing output.

- Increased Flexibility The advanced machining capabilities provide manufacturers with the flexibility to produce a wider variety of parts without extensive downtime for setup changes.

- Enhanced Part Quality The precise alignment and machining process create parts with superior quality and consistency, which is crucial for applications where failure is not an option.

- Streamlined Operations An integrated system with speed and ease of operation allows businesses to streamline their entire production process, leading to improvements in overall efficiency.

Conclusion

The CMC650U five-axis linkage vertical machining center stands out as a premier choice for industries demanding precision, flexibility, and speed in machining processes. With its impressive specifications and capabilities, it epitomizes the future of manufacturing technology, ensuring users remain competitive in an ever-evolving market.

Investing in the CMC650U means investing in a machine that not only meets current production needs but also anticipates future demands, making it an invaluable asset for any manufacturing facility. With its powerful performance and innovative features, the CMC650U promises to elevate your machining operations to unprecedented levels of efficiency and quality. Embrace the future of machining with the CMC650U and witness transformative changes in your production capabilities.

Categories

Automation conneting equipment auxiliary machine Foam machinery Mattress machines Metal processing machine Plywood working machine Solid wood working machineTags