Comprehensive Overview of the Knee Type Milling Machine

Comprehensive Overview of the Knee Type Milling Machine

Introduction

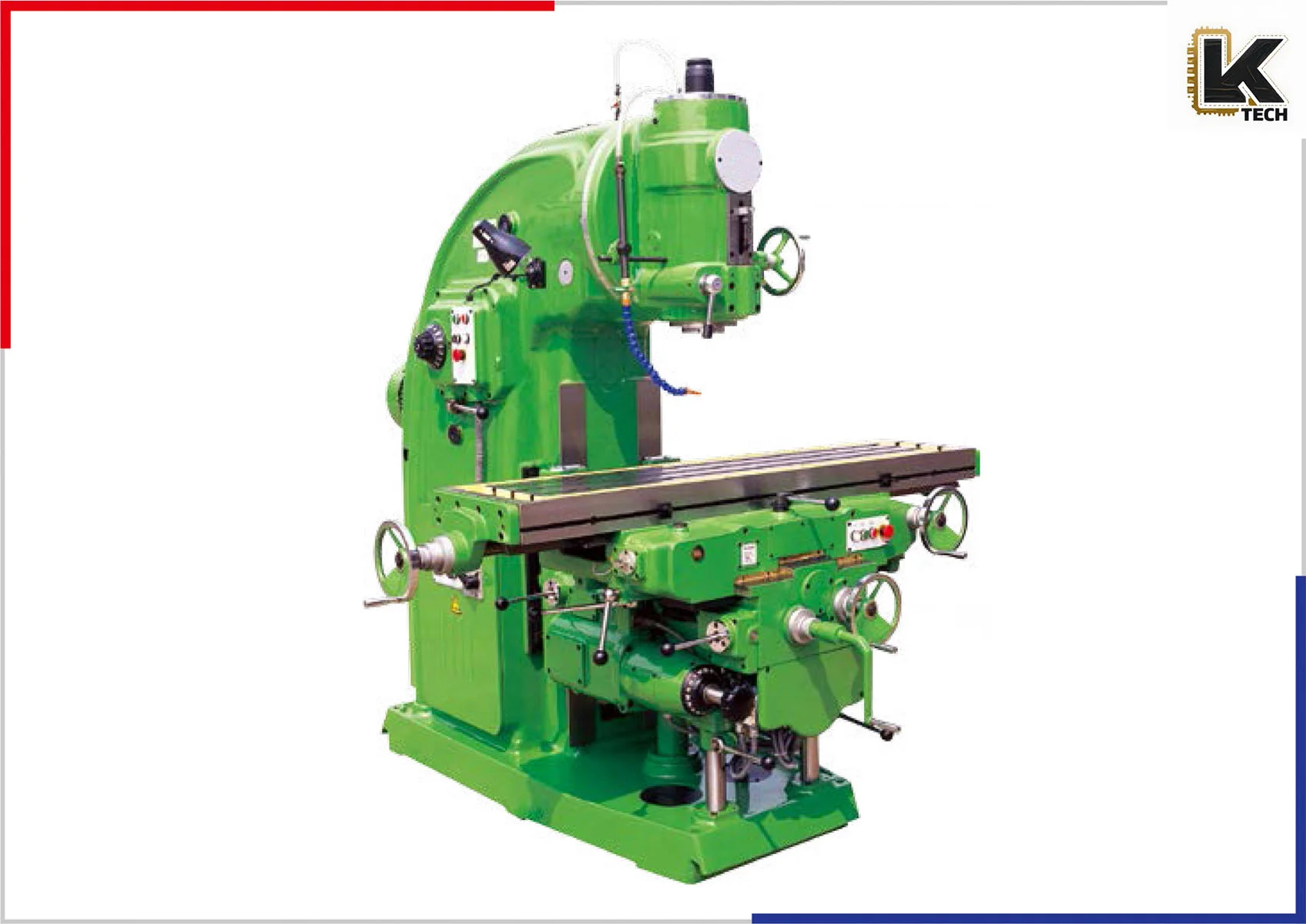

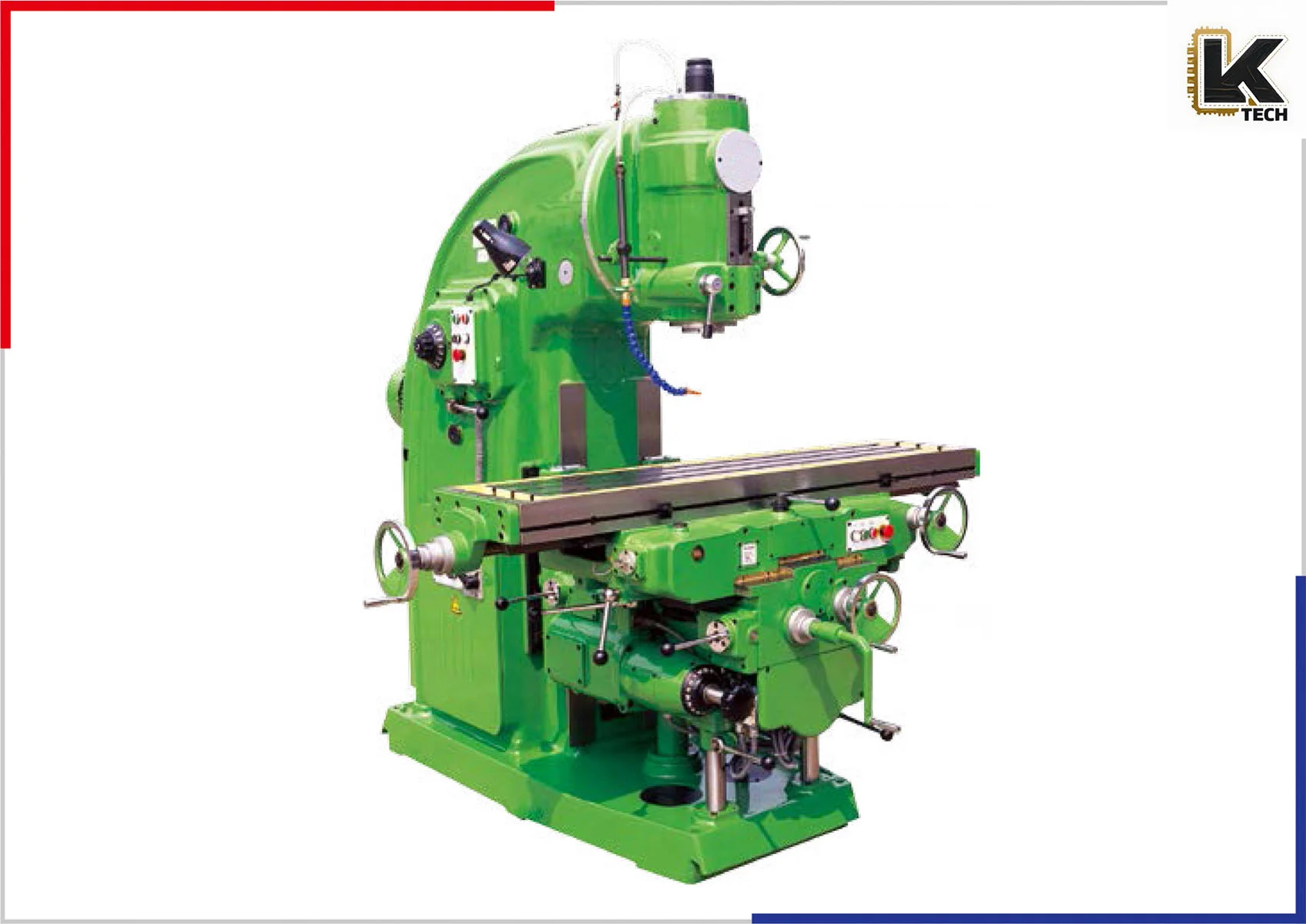

In the realm of manufacturing and machining, the knee-type milling machine holds an essential place due to its versatile functionalities and robust design. Comprising both manual and automated features, these machines are invaluable to operators seeking precision and reliability. This product description focuses on the features, specifications, and benefits of the knee-type milling machines X5040 and X5032, as well as its variants X6140 and X6132, illustrating why they are a preferred choice for many industries.

Design and Construction

The knee-type milling machine is distinguished by a conventional design featuring a solid base, a knee elevating mechanism, and a spindle head capable of swiveling to accommodate various milling operations. The base supports the entire machine structure, ensuring stability during operation. The knee mechanism enables vertical adjustments of the table, allowing users to perform precise cuts on different workpieces.

The durable body, crafted from high-quality cast iron, provides robustness and minimizes vibrations during milling operations. The bright green paint finish not only enhances the aesthetic appeal but also provides protection against corrosion, extending the machine’s lifespan.

Features and Capabilities

- Table Size and Load Capacity:

- X5040: The spacious table measures 1700 mm x 400 mm, enabling the machining of larger workpieces with a maximum load capacity of 800 kg.

- X5032: Offers a slightly smaller table size of 1320 mm x 320 mm, supporting a maximum load of 500 kg, perfect for smaller components.

- X6140: Retains similar dimensions to the X5040, providing a robust platform for extensive machining tasks.

- X6132: This variant scales down the table to 1320 mm x 320 mm, maintaining efficiency for lighter operations.

- Travel Specifications:

- The machines come with both manual and automatic longitudinal, transverse, and vertical travel functionalities, allowing for intricate and precise positioning of the workpiece relative to the milling cutter.

- For instance, the X5040 boasts a longitudinal travel of 900/880 mm, transverse travel of 315/300 mm, and vertical travel of 385/365 mm, ensuring maximum versatility in machining.

- Cutting Feed Speed:

- With cutting feed speeds ranging from a minimum of 8 mm/min to a maximum of 1180 mm/min in both longitudinal and transverse directions, operators can select a speed appropriate for their specific machining requirements.

- The X6140 and X6132 machines also provide similar cutting feed speeds, making them optimal for a variety of materials and tooling requirements.

- Rapid Feed Speed:

- The machines are designed with rapid feed speeds, allowing for quick movements of the milling table during setup or repositioning. With rapid feed speeds of up to 2300 mm/min in all directions, users can enhance their productivity significantly.

- Spindle Specifications:

- The spindle speed range, ranging from 30 to 1500 RPM, allows users to use various tooling options tailored for specific materials. The 18-step spindle speed adjustment further enhances flexibility, enabling certain applications to run optimally.

- Swivel Spindle Capability:

- With a maximum swivel angle of ±45°, the machines provide operators with the ability to angle the spindle for complex machining tasks, such as angular cuts and contours on workpieces.

| Specifications | Units | X6140 | X6132 |

|---|---|---|---|

| Table size | mm | 1700 × 400 | 1320 × 320 |

| Number/Width/Distance of T-slot | mm | 3–18–90 | 3–18–70 |

| Max. load of table | kg | 800 | 500 |

| Longitudinal travel (manual/auto) | mm | 900/880 | 700/680 |

| Transverse travel (manual/auto) | mm | 315/300 | 255/240 |

| Vertical travel (manual/auto) | mm | 380/360 | 320/300 |

| Cutting feed speed | mm/min | longitudinal/transverse: 23.5–1180, vertical:8–394 | longitudinal:23.5–1180, transverse:15–786, vertical:394 |

| Rapid feed speed | mm/min | longitudinal:2300, transverse:2300, vertical:770 | longitudinal:2300, transverse:1533, vertical:770 |

| Spindle speed range | rpm | 30–1500 | 30–1500 |

| Spindle speed step | 级 (steps) | 18 | 18 |

| Distance between spindle axis and table surface | mm | 30–410 | 30/350 |

| Spindle motor power | Kw | 11 | 7.5 |

| Overall dimension | mm | 2560 × 2130 × 1800 | 2294 × 1770 × 1665 |

| Machine weight | Kg | 3850 | 2650 |

| Specifications | Units | X5040 | X5032 |

|---|---|---|---|

| Table size | mm | 1700 × 400 | 1320 × 320 |

| Number/Width/Distance of T–slot | mm | 3–18–90 | 3–18–70 |

| Max. load of table | kg | 800 | 500 |

| Longitudinal travel (manual/auto) | mm | 900/880 | 700/680 |

| Transverse travel (manual/auto) | mm | 315/300 | 255/240 |

| Vertical travel (manual/auto) | mm | 385/365 | 350/330 |

| Cutting feed speed | mm/min | longitudinal/transverse: 23.5–1180, vertical:8–394 | longitudinal:23.5–1180, transverse:17–786, vertical:8–394 |

| Rapid feed speed | mm/min | longitudinal:2300, transverse:2300, vertical:770 | longitudinal:2300, transverse:1533, vertical:770 |

| Spindle speed range | rpm | 30–1500 | 30–1500 |

| Spindle speed step | 级 (steps) | 18 | 18 |

| Spindle travel | mm | 85 | 70 |

| Max. swivel angle of spindle | ±45° | ±45° | ±45° |

| Distance between spindle nose and table surface | mm | 130–515 | 60/430 |

| Spindle motor power | Kw | 11 | 7.5 |

| Overall dimension | mm | 2560 × 2130 × 2298 | 2294 × 1770 × 1960 |

| Machine weight | Kg | 4250 | 2800 |

Efficiency and User-Friendliness

Operating the knee-type milling machine is designed to be user-friendly. The control panel allows easy access to adjust feed rates, spindle speeds, and other parameters, perfect for both experienced machinists and newcomers. Manual handles are placed strategically to provide operators with better leverage and control over their tasks.

The ergonomic layout of controls and adjustments promotes ease of use during operations, reducing fatigue and increasing efficiency. Moreover, the intuitive design helps minimize learning curves when training new operators, ensuring a seamless integration into workflows.

Applications

Knee-type milling machines are utilized across various industries including:

- Aerospace Manufacturing: For precise component fabrication.

- Automotive Industry: In the production of engine parts, brackets, and components.

- Metalworking: Ideal for job shops and tool rooms focusing on custom machining.

- Educational Institutions: Providing hands-on training environments for engineering students and apprentices.

Maintenance and Care

To ensure optimal performance and longevity, routine maintenance is essential. Operators should adhere to the following guidelines:

- Regularly lubricate moving parts to prevent wear and tear.

- Ensure all fasteners and bolts are secure to maintain alignment and stability.

- Clean the table and components after each use to prevent material buildup.

- Periodically inspect electrical connections and settings to guarantee safety and operational integrity.

Conclusion

In conclusion, the knee-type milling machine, including models like the X5040, X5032, X6140, and X6132, embodies reliability, efficiency, and versatility, making them indispensable assets in any machining environment. With robust construction, advanced functionalities, and ease of operation, these machines excel in meeting the rigorous demands of milling tasks. By selecting a knee-type milling machine, you are choosing a tool that not only boosts productivity but also empowers your operations to achieve superior results with precision—ensuring quality craftsmanship across various manufacturing processes.

Invest in a knee-type milling machine today and elevate your machining capabilities to the next level!

Categories

Automation conneting equipment auxiliary machine Foam machinery Mattress machines Metal processing machine Plywood working machine Solid wood working machineTags