Linear Sharpener ITE256, ITE257B, ITE2510A, ITE2510B, ITE2510BC, ITE2515A: The Ultimate Tool for Precision Blade Sharpening

In the contemporary industrial landscape, the efficiency and effectiveness of equipment play a crucial role in production outcomes. Whether operating in the fields of forestry, textiles, furniture, or any heavy-duty manufacturing process, managing equipment longevity hinges on the maintenance of cutting implements. Enter the Linear Sharpener series, which includes the notable models: ITE256, ITE257B, ITE2510A, ITE2510B, ITE2510BC, and ITE2515A. These machines have been meticulously engineered to provide top-tier sharpening capabilities for various types of cutting blades, ensuring maximum performance and durability.

Overview of the Linear Sharpener Series

The Linear Sharpener series offers a range of models designed to cater to different types of knives used in diverse industries. These machines are essential for operations that demand precision cutting, as they enhance blade sharpness and efficiency while minimizing operational downtime due to dull blades.

Equipped with advanced features and innovative technology, each model provides specialization tailored to distinct industrial needs, ensuring operators have access to reliable and efficient sharpening solutions.

Key Features

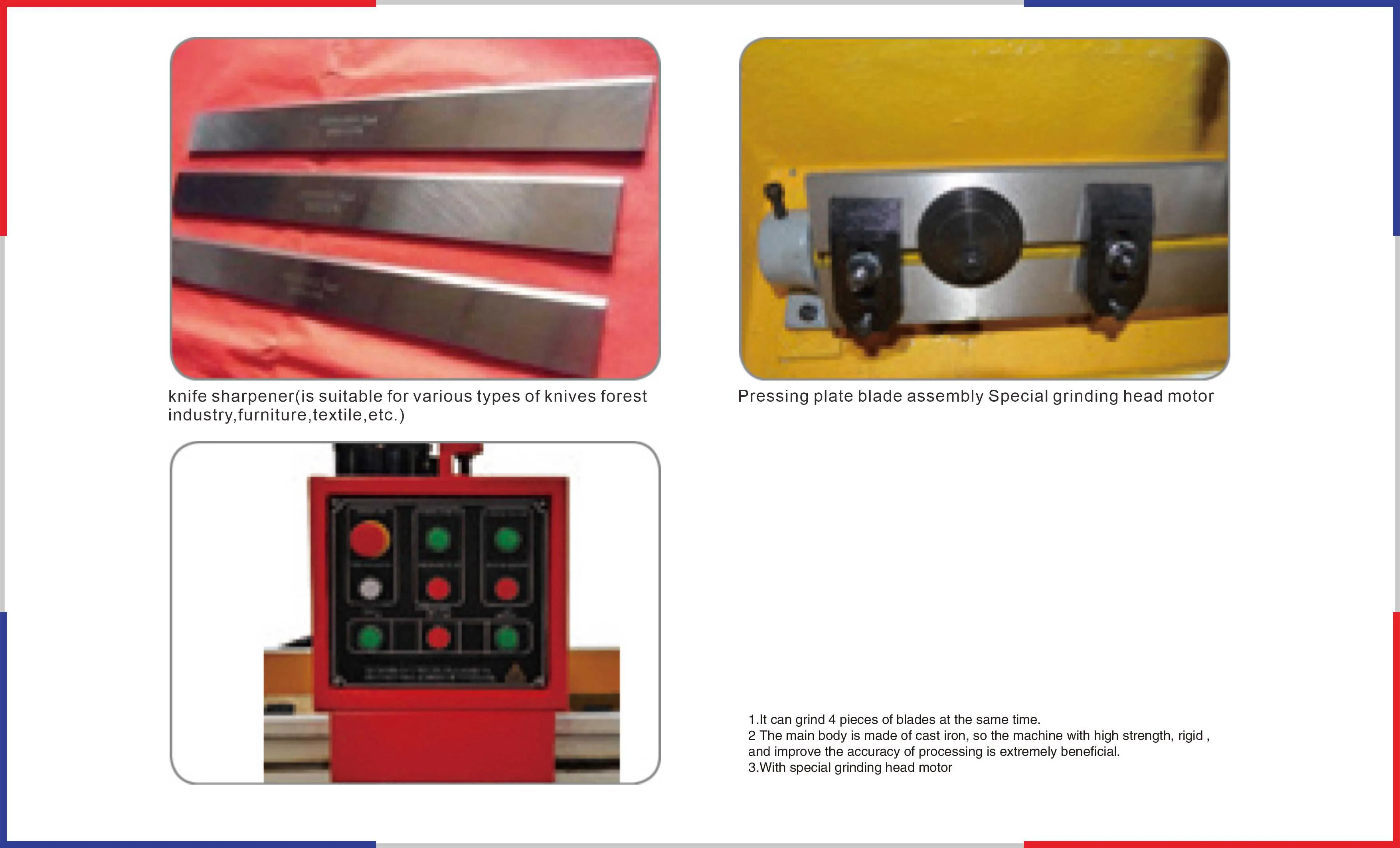

- Multi-blade Sharpening Capability: One of the standout features of the Linear Sharpener is its ability to sharpen multiple blades simultaneously. With the capability to process up to four blades at once, inefficiencies related to frequent sharpening are significantly reduced. Industries can benefit from faster turnaround times and enhanced productivity.

- Robust Construction: The main body of the sharpener is constructed from high-strength cast iron, providing exceptional stability during operations. This contributes to reduced vibrations and improved accuracy — vital for achieving optimal sharpening results.

- Precision Technology: The incorporation of high-precision components, such as the imported ball screws, ensures smooth movement and reliability. These components work together to maintain alignment during sharpening, thereby enhancing overall blade accuracy.

- User-Friendly Control Panel: The advanced control panel is designed for intuitive operation. With clearly marked buttons and indicator lights, users can easily control the sharpening process with a straightforward interface, making the equipment accessible for all levels of operators.

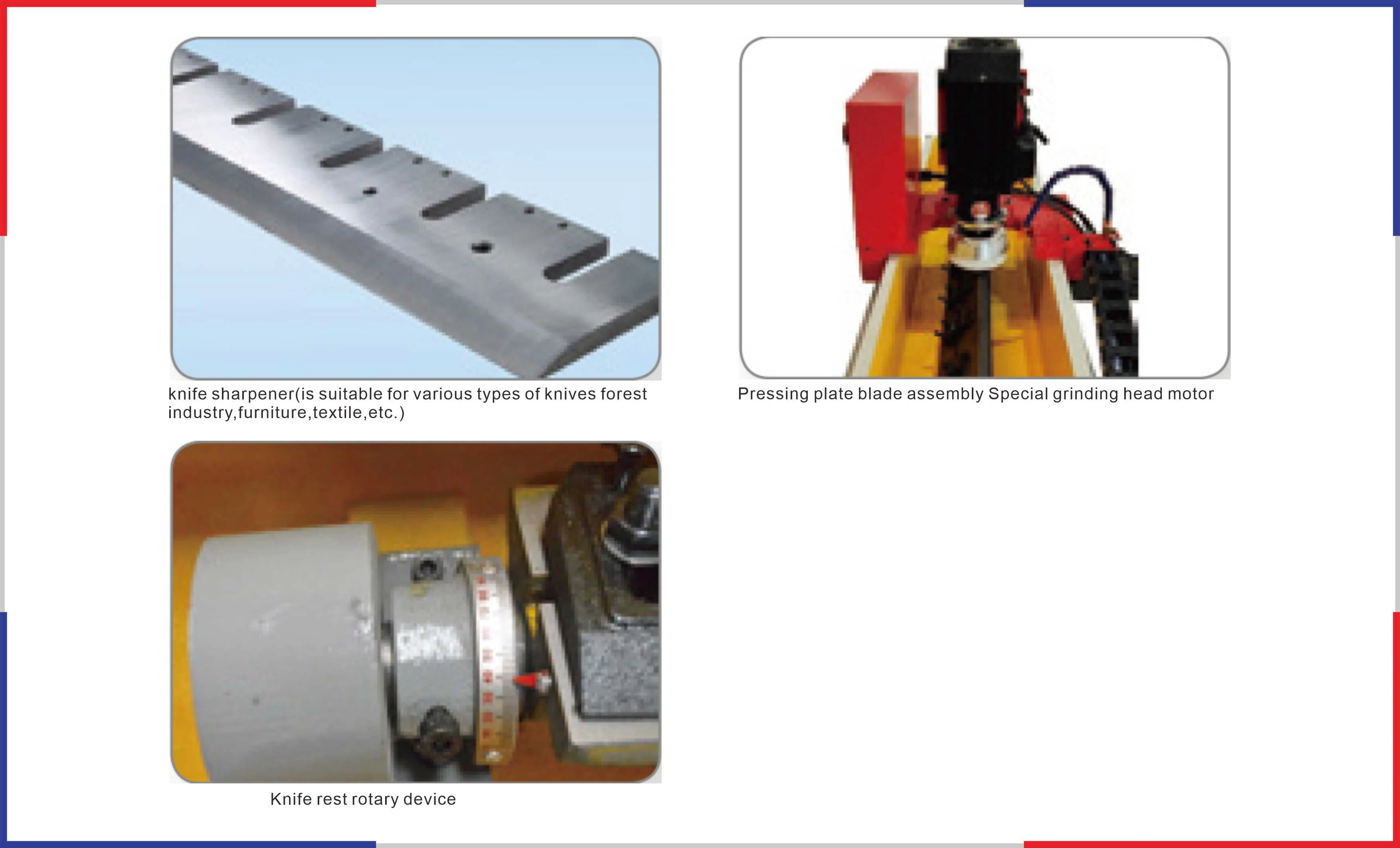

- Versatility Across Blade Types: The Linear Sharpener is adaptable to various knife types used in industries ranging from forestry to textile manufacturing. This versatility makes it an indispensable tool for businesses that utilize a variety of cutting implements.

- Dynamic Grinding Head Motor: Each model integrates a powerful grinding head motor that significantly optimizes sharpening performance. This specialized motor is fine-tuned for consistent results, ensuring every sharpening session delivers sharp blades ready for immediate use.

- Knife Rest Rotary Device: For added convenience, the machine features a knife rest rotary device, allowing for quick adjustments and positioning of blades. This feature enhances the efficiency of the sharpening process, accommodating different blade sizes and shapes with ease.

- Safety Features: Safety is paramount in industrial environments. The Linear Sharpener includes multiple safety mechanisms, ensuring user protection throughout the sharpening process. Emergency stop buttons and fail-safe measures are in place to minimize accidents.

Product Applications

The Linear Sharpener series is suitable for a variety of applications across diverse industries:

- Forestry: Perfect for maintaining chainsaw blades and forestry knives, keeping them sharp for optimal performance.

- Textiles: Essential for fabric cutting blades, where precision cuts are paramount in the production of textiles.

- Furniture Manufacturing: Ideal for woodworking tools that require consistent cutting edges for high-quality finishes.

- Printing Industries: Sharpening of cutting knives used in printing presses for clean, precise cuts.

| Machine Parameters | Specifications |

|---|---|

| Main Motor Power | 1.5 kW |

| Water Pump Power | 40 W |

| Driving Motor Power | 60 W |

| Grinding Wheel Specification | Ø32×Ø125×50mm (Calathiform) |

| Effective Grinding Length | 700 mm |

| Grinding Wheel Rotate Speed | 2800 r/min |

| Work Bench Rotation Angle | ±90° |

| Grinding Head Movement Speed | 0–6 m/min |

| Size | 1150×610×1300 mm |

| Weight | 240 kg |

| Machine Parameters | Specifications |

|---|---|

| Main Motor Power | 1.5 kW |

| Water Pump Power | 40 W |

| Driving Motor Power | 120 W |

| Grinding Wheel Specification | Ø32×Ø150×60 mm |

| Effective Grinding Length | 700 mm |

| Grinding Wheel Rotate Speed | 2800 r/min |

| Work Bench Rotation Angle | ±90° |

| Electromagnetic Size | 140×800 mm |

| Grinding Head Movement Speed | 0–10 m/min (Control) |

| Size | 1660×920×1400 mm |

| Weight | 500 kg |

| Machine Parameters | Specifications |

|---|---|

| Main Motor Power | 1.5 kW |

| Water Pump Power | 40 W |

| Driving Motor Power | 60 W |

| Grinding Wheel Specification | Ø32×Ø125×50 mm (Calathiform) |

| Effective Grinding Length | 1000 mm |

| Grinding Wheel Rotate Speed | 2800 r/min |

| Work Bench Rotation Angle | ±90° |

| Grinding Head Movement Speed | 0–6 m/min |

| Size | 1460×700×1300 mm |

| Weight | 285 kg |

| Machine Parameters | ITE 258B | ITE 2510B | ITE 2515B |

|---|---|---|---|

| Main Motor Power | 1.5 kW | 1.5 kW | 2.2 kW |

| Water Pump Power | 40 W | 40 W | 40 W |

| Driving Motor Power | 120 W | 120 W | 120 W |

| Grinding Wheel Specification | Ø32×Ø150×60 mm | Ø32×Ø150×60 mm | Ø32×Ø150×60 mm |

| Effective Grinding Length | 850 mm | 1000 mm | 1500 mm |

| Grinding Wheel Rotate Speed | 2800 r/min | 2800 r/min | 2800 r/min |

| Work Bench Rotation Angle | ±90° | ±90° | ±90° |

| Electromagnetic Size | 140×850 mm | 140×1000 mm | 160×1500 mm |

| Grinding Head Movement Speed | 0–10 m/min (Frequency Control) | 0–10 m/min (Frequency Control) | 0–10 m/min (Frequency Control) |

| Size | 1730×920×1435 mm | 1865×920×1435 mm | 2660×955×1435 mm |

| Weight | 545 kg | 600 kg | 980 kg |

| Machine parameters | ITE 258BC | ITE 2510BC | ITE 2515BC |

|---|---|---|---|

| Main Motor Power | 1.5Kw | 1.5Kw | 2.2Kw |

| Water Pump Power | 40w | 40w | 40w |

| Driving Motor Power | 120w | 120w | 120w |

| Grinding Wheel Specification | Φ32×Φ150×60mm | Φ32×Φ150×60mm | Φ32×Φ150×60mm |

| Effective Grinding Length | 850mm | 1000mm | 1500mm |

| Grinding Wheel Rotate Speed | 2800r/min | 2800r/min | 2800r/min |

| Work Bench Rotation Angle | ±90° | ±90° | ±90° |

| Electromagnetic size | 140×850mm | 140×1000mm | 160×1500mm |

| Grinding Head Movement Speed | 0–10m/min(Frequency Control) | 0–10m/min(Frequency Control) | 0–10m/min(Frequency Control) |

| Size | 1730×920×1435mm | 1865×920×1435mm | 2660×955×1435mm |

| Weight | 545KG | 600KG | 980KG |

| Machine parameters | specifications |

|---|---|

| Main Motor Power | 5.5Kw |

| Water Pump Power | 90w |

| Driving Motor Power | 750w |

| Grinding Wheel Specification | Φ145xΦ205x115mm |

| Effective Grinding Length | 1500mm |

| Grinding Wheel Rotate Speed | 1440r/min |

| Electric Disk Rotation Angle | ±90 |

| Electromagnetic size | 190mmx1680mm |

| Grinding Head Movement Speed | 0-12m/min(Frequency Control) |

| Size | 3200x980x1700mm |

| Weight | 1800KG |

Conclusion

In a world dictated by precision and efficiency, the Linear Sharpener ITE256, ITE257B, ITE2510A, ITE2510B, ITE2510BC, and ITE2515A stands out as an indispensable tool for any industry reliant on superior cutting tools. Its combination of robust construction, precision technology, and the ability to sharpen multiple blades concurrently makes it perfect for enhancing operational efficiency and product quality. Investing in a Linear Sharpener means investing in the future of your operations, ensuring every cut is perfect, every time.

Upgrade your sharpening capabilities today and witness the transformation in your production processes with the Linear Sharpener series.

Categories

Automation conneting equipment auxiliary machine Foam machinery Mattress machines Metal processing machine Plywood working machine Solid wood working machineTags