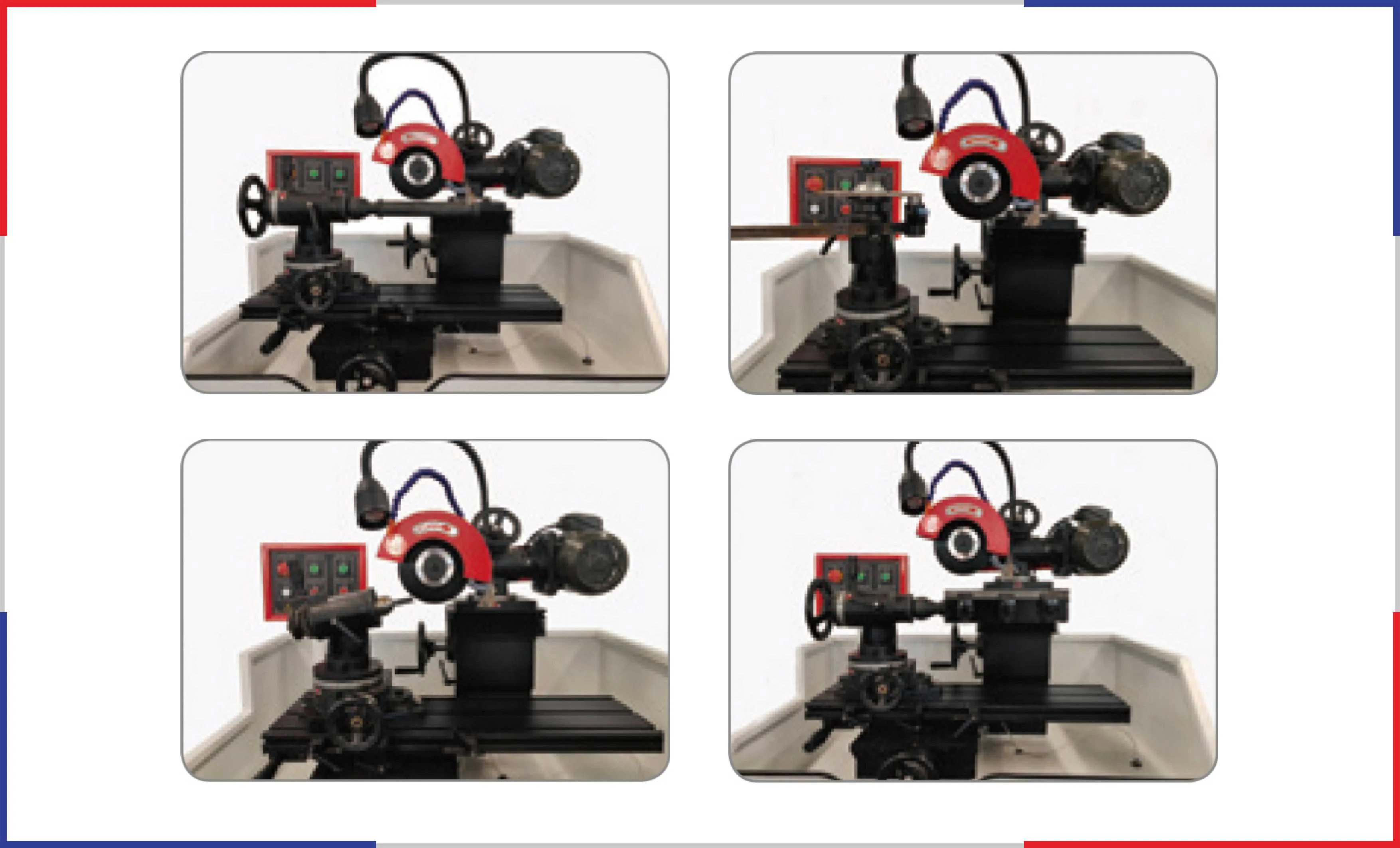

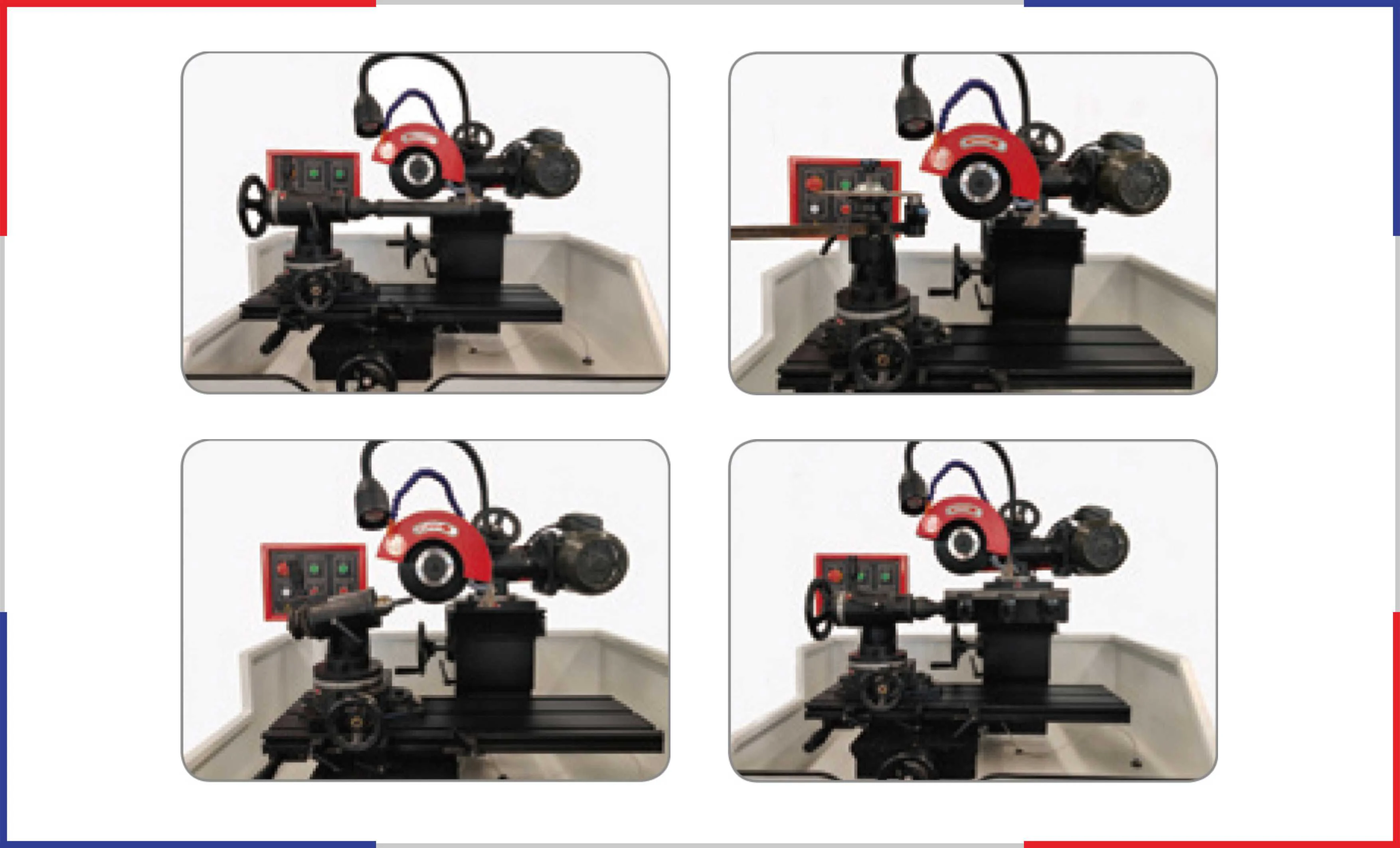

ITE55-CNC & ITE2718 & ITE2719B & ITE2720: A Cutting-Edge Multiaxis Sharpening Solution

Overview

In the dynamic world of precision engineering and metalwork, the need for high-quality, reliable sharpening tools is paramount. The ITE55-CNC, ITE2718, ITE2719B, and ITE2720 model series from K-Tech represent the pinnacle of multifunctional sharpening technology. These machines embody a fusion of sophisticated engineering, user-friendly design, and tremendous versatility. Key features include advanced CNC controls, a range of capabilities for various tools, and robust constructions, making them invaluable assets for both small workshops and large-scale manufacturing facilities.

Detailed Specifications and Features

ITE55-CNC: The Ultimate in Precision

| Parameter | Specification |

|---|---|

| Total Weight | 3.6 T |

| Total Power | 13 kW |

| Countertop (L × W) | 500 mm × 600 mm |

| Travel (X/Y/Z-axis) | 220 mm / 380 mm / 500 mm |

| Spindle Runout | <0.01 mm |

| Machine Dimensions | 1990×1990×2150 mm |

| Maximum Diameter of Grinding Wheel | 200 mm |

| Maximum Grindable Tool Length | 200 mm |

| Maximum Grindable Tool Diameter | 300 mm |

| Machining Tool Runout | <0.03 (<0.01) |

| Machining Tool Finish | 0.2 |

The ITE55-CNC is a robust, computer numerically controlled machine designed for high precision sharpening. This model includes:

- Motor Power: 0.55 kW, ensuring strong performance for even the most demanding tasks.

- Cutter Rest Turning Diameter: 400 mm, allowing for substantial tooling options.

- Cutter Rest Stroke: 300 mm, providing extensive range for adjustment.

- Grinding Wheel Specification: 10 x Ø32(16) x Ø150 mm, catering to various tool types.

- Grinding Wheel Rotate Speed: 3500 rpm, offering efficient performance and swift operations.

- Grinding Wheel Rotation Angle: ±45°, adding versatility in sharpening angles.

- Applicable Saw Blade Size: Ø105 - Ø500 mm, which accommodates a wide variety of cutting tools.

- Dimensions: 1060 x 760 x 1300 mm, making it compact yet highly efficient.

- Weight: 280 kg, indicative of its robust construction ensuring stability during operation.

ITE2718 & ITE2719B: Versatile Multifunction Sharpeners

The ITE2718 and ITE2719B models are compact yet powerful multifunction sharpeners designed for versatility. While both share core functionalities, they come with specific enhancements that widen their application scope.

| Machine Parameters | Specifications |

|---|---|

| Power of Motor | 0.41 kW |

| Cutter Rest Turning Diameter | 360 mm |

| Cutter Rest Stroke | 280 mm |

| Grinding Wheel Specification | 10×Ø32(16)×Ø150 |

| Grinding Wheel Rotate Speed | 3500 r/min |

| Grinding Wheel Rotation Angle | ±45° |

| Applicable Saw Blade Size | Ø105–Ø500 |

| Size | 820×630×1250 mm |

| Weight | 200 kg |

ITE2718 Features:

- Motor Power: 0.55 kW.

- Cutter Rest Turning Diameter: 380 mm.

- Cutter Rest Stroke: 350 mm.

- Grinding Wheel Specification: 10 x Ø32(16) x Ø150 mm.

- Grinding Wheel Rotate Speed: 3500 rpm.

- Grinding Wheel Rotation Angle: ±45°.

- Applicable Saw Blade Size: Ø105 - Ø500 mm.

- Dimensions: 970 x 760 x 1300 mm.

- Weight: 250 kg.

ITE2719B Enhancements:

The ITE2719B, meanwhile, boasts similar features but offers unique advantages in user interface and operational flexibility:

- Dimensions and specifications closely resemble the ITE2718, with slight adjustments for functionality.

- Enhanced ergonomics for ease of use, focus on compact footprint without sacrificing performance.

| Machine Parameters | Specifications |

|---|---|

| Power of Motor | 0.55 kW |

| Outer Rest Turning Diameter | 380 mm |

| Outer Rest Stroke | 350 mm |

| Grinding Wheel Specification | 10×Ø32(16)×Ø150 |

| Grinding Wheel Rotate Speed | 3500 r/min |

| Grinding Wheel Rotation Angle | ±45° |

| Applicable Saw Blade Size | Ø105–Ø500 |

| Size | 970×760×1300 mm |

| Weight | 250 kg |

ITE2720: Advanced Functions for Professional Users

The ITE2720 model stands out with advanced functionalities tailored for professional and industrial applications.

- Powerful Motor: Embedded with a powerful motor to guarantee heightened precision and speed.

- Cutting Edge Technology: Features such as automatic tool detection and integrated software streamline your workflow.

- Versatile Grinding Options: Like its counterparts, offers various grinding methods including saw blades, milling cutters, and drilling tools.

| Machine Parameters | Specifications |

|---|---|

| Power of Motor | 0.55 kW |

| Cutter Rest Turning Diameter | 400 mm |

| Cutter Rest Stroke | 300 mm |

| Grinding Wheel Specification | 10×Ø32(16)×Ø150 |

| Grinding Wheel Rotate Speed | 3500 r/min |

| Grinding Wheel Rotation Angle | ±45° |

| Applicable Saw Blade Size | Ø105–Ø500 |

| Size | 1060×760×1300 mm |

| Weight | 280 kg |

Cutting Tool Compatibilities

One of the standout features across the ITE series is its capability for various cutting tools:

- Round Saw Blade Grinding Device: Designed for effective sharpening of circular saw blades.

- Milling Cutter & Drilling Cutter Device: Enhances the ability to sharpen complex shapes, ensuring maintenance of precise dimensions.

- Linear Cutter Grinding Device: Perfect for heavy-duty applications where linear cuts are required.

- Molding Cutter Grinding Device: Specialized adaptability for extensive profiling and shaping tasks.

User-Centric Design

K-Tech has meticulously designed the ITE series with the operator in mind. Key user-friendly features include:

- Intuitive Control Panel: Simplifies the operational learning curve.

- Adjustable Brightness Work Light: Ensures superior visibility during sharpening, crucial for precision work.

- Stable Base Structure: Reduces vibration and enhances operation accuracy, vital for achieving consistent results.

Maintenance and Sustainability

Maintenance requirements for the ITE series are minimal. The robust architecture of these machines means they are built to last, with significant user support resources available for troubleshooting and upkeep. Regular cleaning and inspection procedures ensure prolonged machine lifespan and sustained performance.

Applications and Industries

The versatility of the ITE series makes them suitable for a multitude of industries, including but not limited to:

- Manufacturing: For the production of cutting tools and other precision instruments.

- Woodworking: Essential for managing blade sharpness and longevity in woodworking operations.

- Metal Fabrication: Ensures consistent results with a multitude of metalworking tools.

- Automotive and Aerospace Sectors: Perfect for maintaining the sharpness of specialized cutting tools to adhere to rigorous standards.

Conclusion

In conclusion, the ITE55-CNC, ITE2718, ITE2719B, and ITE2720 represent state-of-the-art solutions in multiaxis sharpening technology. Their robust designs, extensive capabilities, and user-friendly interfaces make them ideal for a wide array of industries. Investing in the ITE series means securing the reliability, precision, and versatility needed to thrive in today’s competitive marketplace.

As you explore the options, consider how these machines can enhance your operations, ensuring that your tools maintain the level of sharpness and precision necessary for high-quality output. Whether you’re a small workshop or an industrial giant, these sharpening solutions will play a crucial role in your success.

Categories

Automation conneting equipment auxiliary machine Foam machinery Mattress machines Metal processing machine Plywood working machine Solid wood working machineTags