Universal Cutter Grinding Machine ITE2719B & ITE2720

In the realm of advanced workshop tools and machinery, the Universal Cutter Grinding Machine ITE2719B & ITE2720 stands as a modern solution for various cutting, grinding, and machining operations. Designed to cater to the diverse needs of professionals in woodworking, metalworking, and manufacturing industries, these machines are essential for maintaining the sharpness and precision of cutting tools. Delivering exceptional accuracy, versatility, and durability, the ITE2719B and ITE2720 are engineered to maximize productivity while ensuring top-notch finishes on various cutting edges.

Key Features and Specifications

ITE2719B Specifications:

- Cutter Rest Turning Diameter: 380mm

- Grinding Wheel Specification: 10 x Ø 32 x (Ø 16) x Ø 150mm

- Cutter Rest Stroke: 300mm

- Grinding Wheel Rotate Speed: 3500r/min

- Grinding Wheel Turning Speed: ±45°

- Motor Power: 0.59kW

- Applicable Saw Blade Size: 105-500mm

- Overall Size: 950 x 750 x 1350mm

ITE2720 Specifications:

- Cutter Rest Turning Diameter: 400mm

- Grinding Wheel Specification: 10 x Ø 32 x (Ø 16) x Ø 150mm

- Cutter Rest Stroke: 300mm

- Grinding Wheel Rotate Speed: 3500r/min

- Grinding Wheel Turning Speed: ±45°

- Motor Power: 0.59kW

- Applicable Saw Blade Size: 105-500mm

- Overall Size: 1040 x 720 x 1300mm

Versatility in Operations

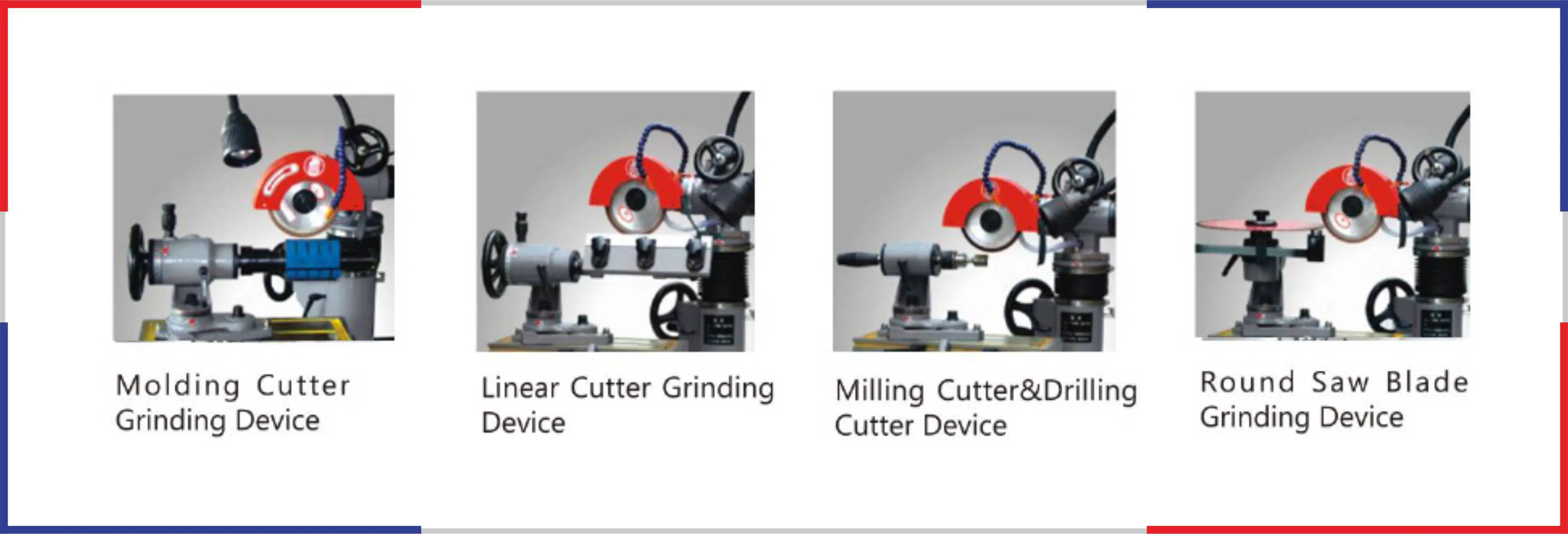

The ITE2719B and ITE2720 machines are designed with versatility in mind, featuring multiple grinding devices to cater to various cutting tools. The included options range from molding cutter grinding devices to linear cutter grinding devices, milling cutter and drilling cutter devices, and round saw blade grinding devices. This flexibility allows users to maintain and enhance the performance of various tools while maximizing their workshop productivity.

Each of these devices serves unique purposes:

- Molding Cutter Grinding Device: Ideal for those engaged in woodworking projects requiring intricate shapes and designs, enabling users to achieve precision cuts effortlessly.

- Linear Cutter Grinding Device: Perfect for providing a sharp edge on straight cutting tools, enhancing linear cutting accuracy.

- Milling Cutter and Drilling Cutter Device: This device allows for the grinding of milling tools and drill bits, ensuring optimal performance during metalworking tasks.

- Round Saw Blade Grinding Device: Specifically designed for the maintenance and sharpening of circular saw blades, this device enhances the longevity and efficiency of the cutting tools.

Precision Engineering

Both the ITE2719B and ITE2720 machines are engineered to provide accurate cuts and sharp edges. The grinding wheel’s rotating speed of 3500r/min is optimal for high-quality finishes while ensuring the materials are not overheated during the grinding process. The ±45° grinding wheel turning capability allows for intricate manipulations and adjustments to achieve the desired cutting angle, ensuring users can tackle a wide array of cutting tools with consistent precision.

The adjustable cutter head enhances flexibility, allowing users to fine-tune the cutting tool positioning for their specific requirements. This feature significantly streamlines the process, as adjustments can be made easily without compromising the machine’s structural integrity or performance.

Ergonomic Design and User-Friendly Interface

Both variants of the Universal Cutter Grinding Machine exhibit an ergonomic design that prioritizes user comfort and efficiency. The intuitive control panel features easy-to-use buttons and indicators that simplify machine operation, ensuring that even novice users can manipulate these advanced tools effectively. The layout allows for quick access to buttons and settings, minimizing downtime during crucial operations.

Furthermore, the included lighting over the workspace provides excellent visibility, enhancing the accuracy of cutting and grinding tasks. The solid base and well-built construction of both machines add stability during operations, reducing vibrations and ensuring consistent results.

Compact Yet Powerful

With their compact dimensions and robust power output, the ITE2719B and ITE2720 are perfect for workshops with limited space. Their overall sizes allow for easy integration into existing setups without significant spatial restrictions. Despite their compact size, these machines offer a high power output, making them capable of handling various tasks seamlessly.

Optional Accessories and Expandability

To further enhance the functionality of both the ITE2719B and ITE2720, users can opt for additional accessories, including tailstocks that add versatility when grinding different tool types. Providing additional support and stability, these accessories promote smoother operation and better end results.

Moreover, the inclusion of high-precision scale rings and control handwheels allows for accurate positioning and adjustments, which are crucial for achieving desired cutting performance.

Maintenance and Durability

These machines are built for durability, designed from high-quality materials that withstand the rigors of constant use. Maintaining the ITE2719B and ITE2720 is straightforward and includes periodic inspections and cleaning to ensure optimal performance. Regular maintenance guarantees a longer lifespan for the machines, affirming them as worthy investments for any serious workshop or manufacturing operation.

Conclusion

In conclusion, the Universal Cutter Grinding Machine ITE2719B & ITE2720 represents a leap forward in tool maintenance technology, combining versatility, durability, and user-friendly features in a compact design. Whether you are a professional craftsman, a manufacturing unit, or a hobbyist, these machines satisfy a critical need in keeping your cutting tools sharp and accurate.

By investing in the ITE2719B & ITE2720, you ensure not just enhanced productivity but also the quality of work your projects demand. From woodworking tasks to complex machining operations, these cutter grinding machines are invaluable tools in achieving superior craftsmanship and precision in every cut.

Categories

Automation conneting equipment auxiliary machine Foam machinery Mattress machines Metal processing machine Plywood working machine Solid wood working machineTags