Universal Milling and Drilling Machine: A Comprehensive Guide

Universal Milling and Drilling Machine: A Comprehensive Guide

Introduction

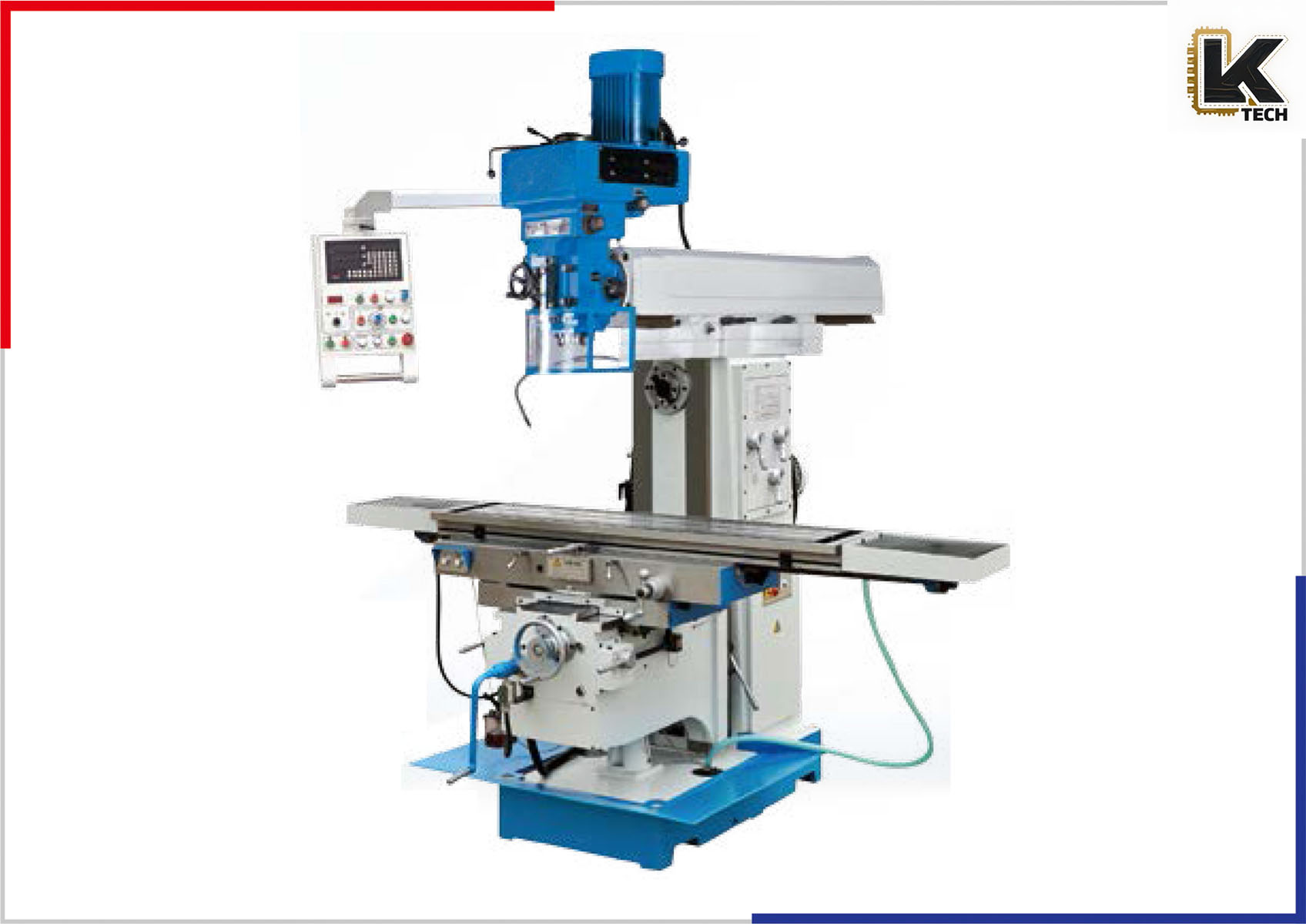

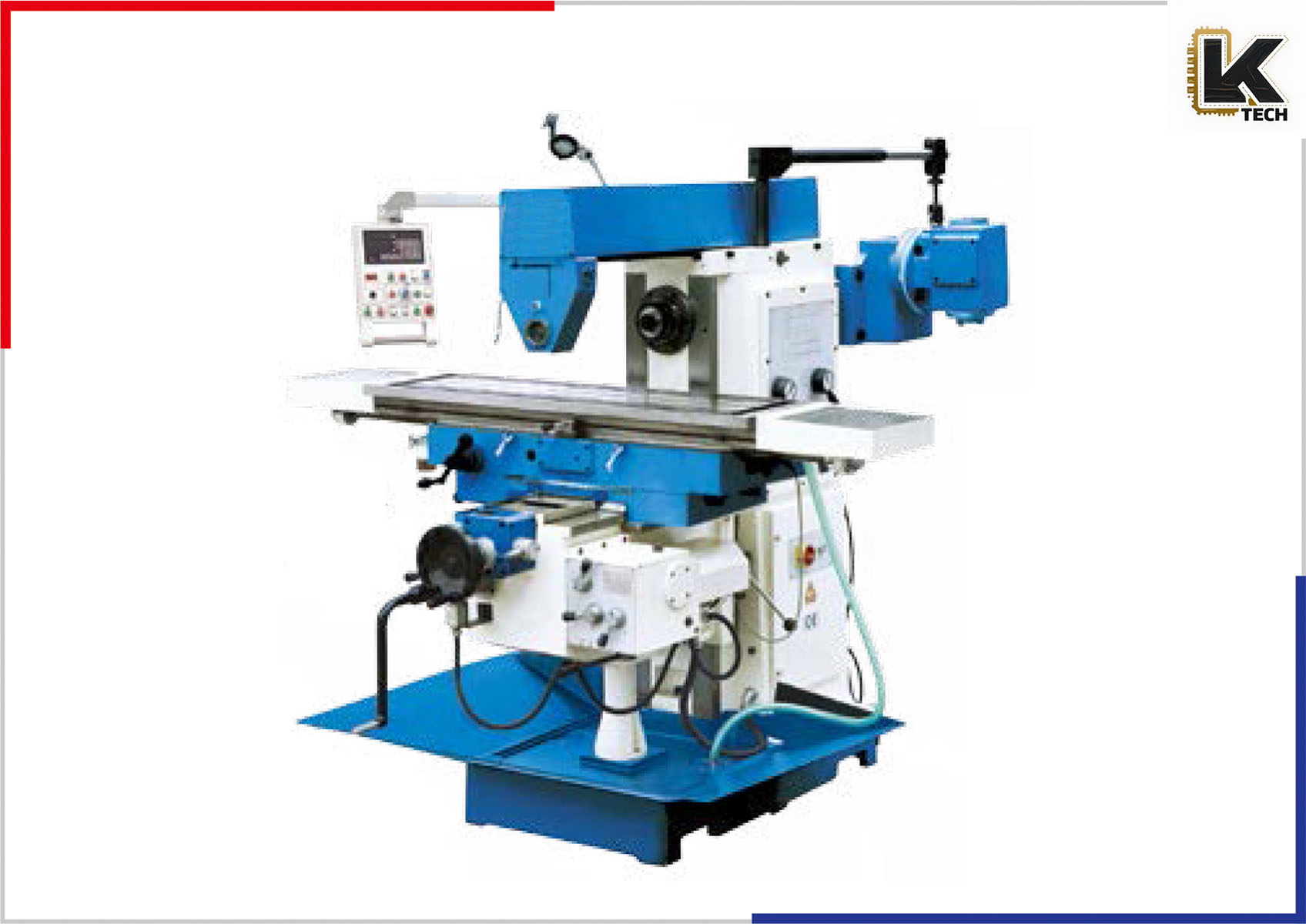

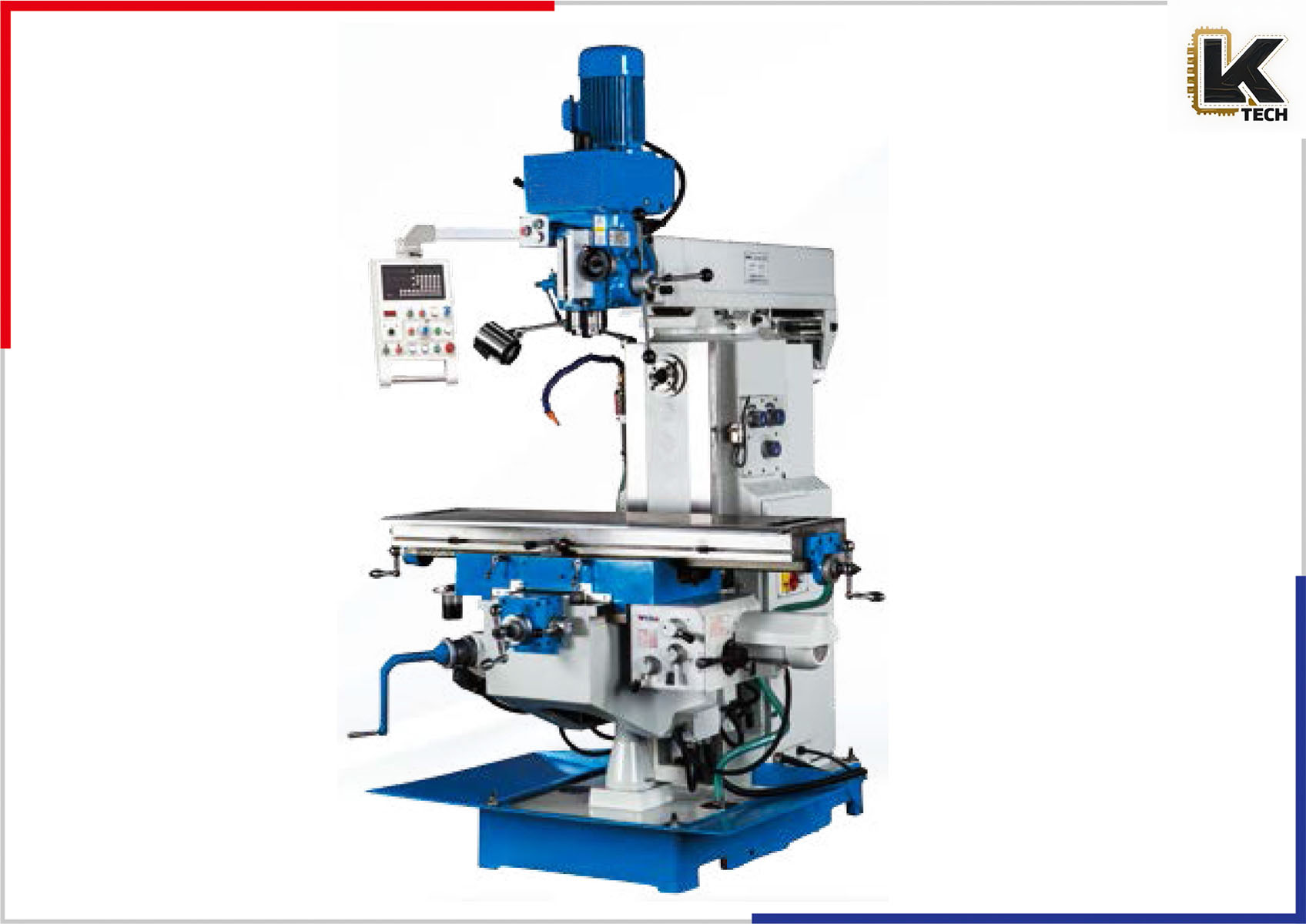

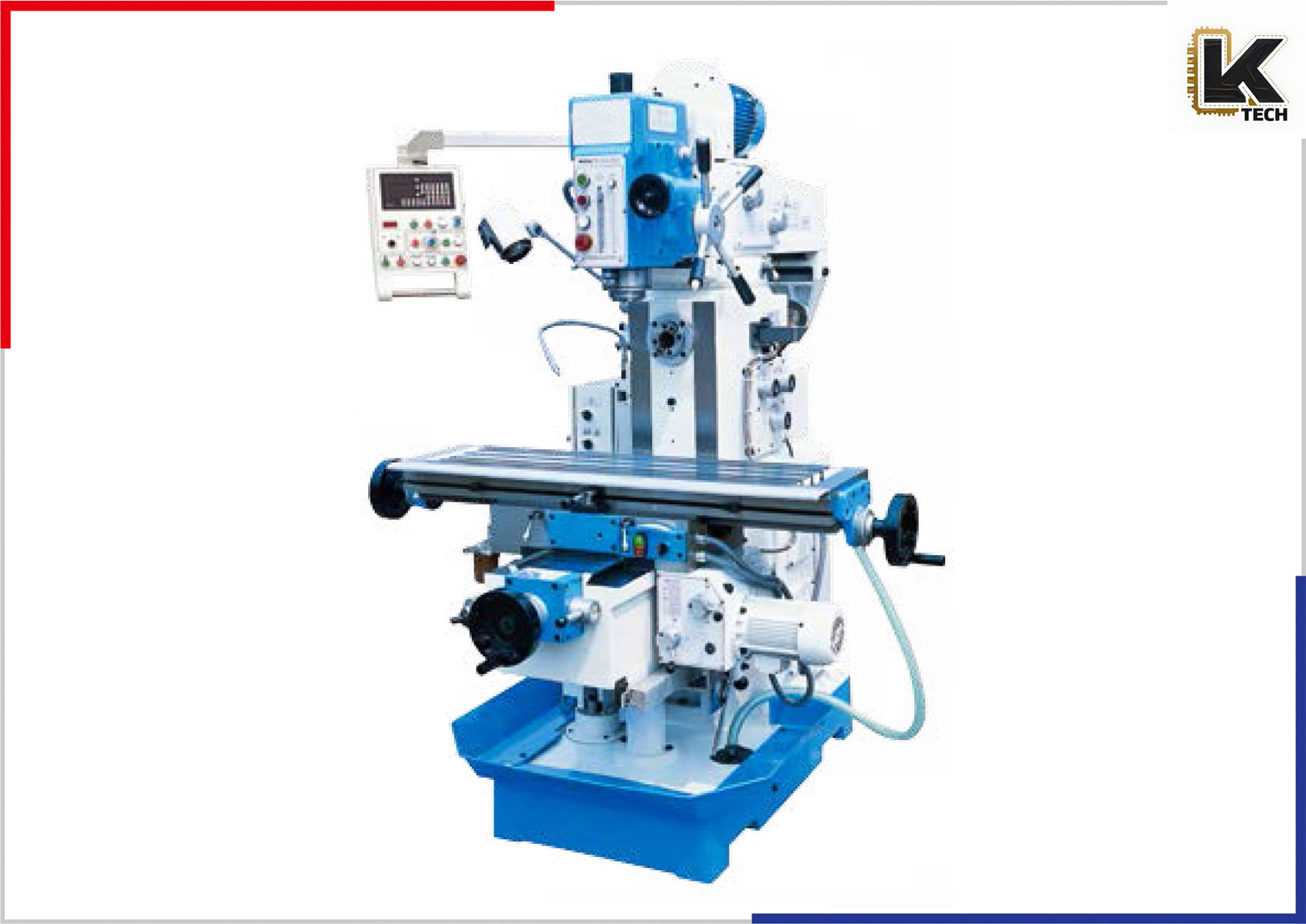

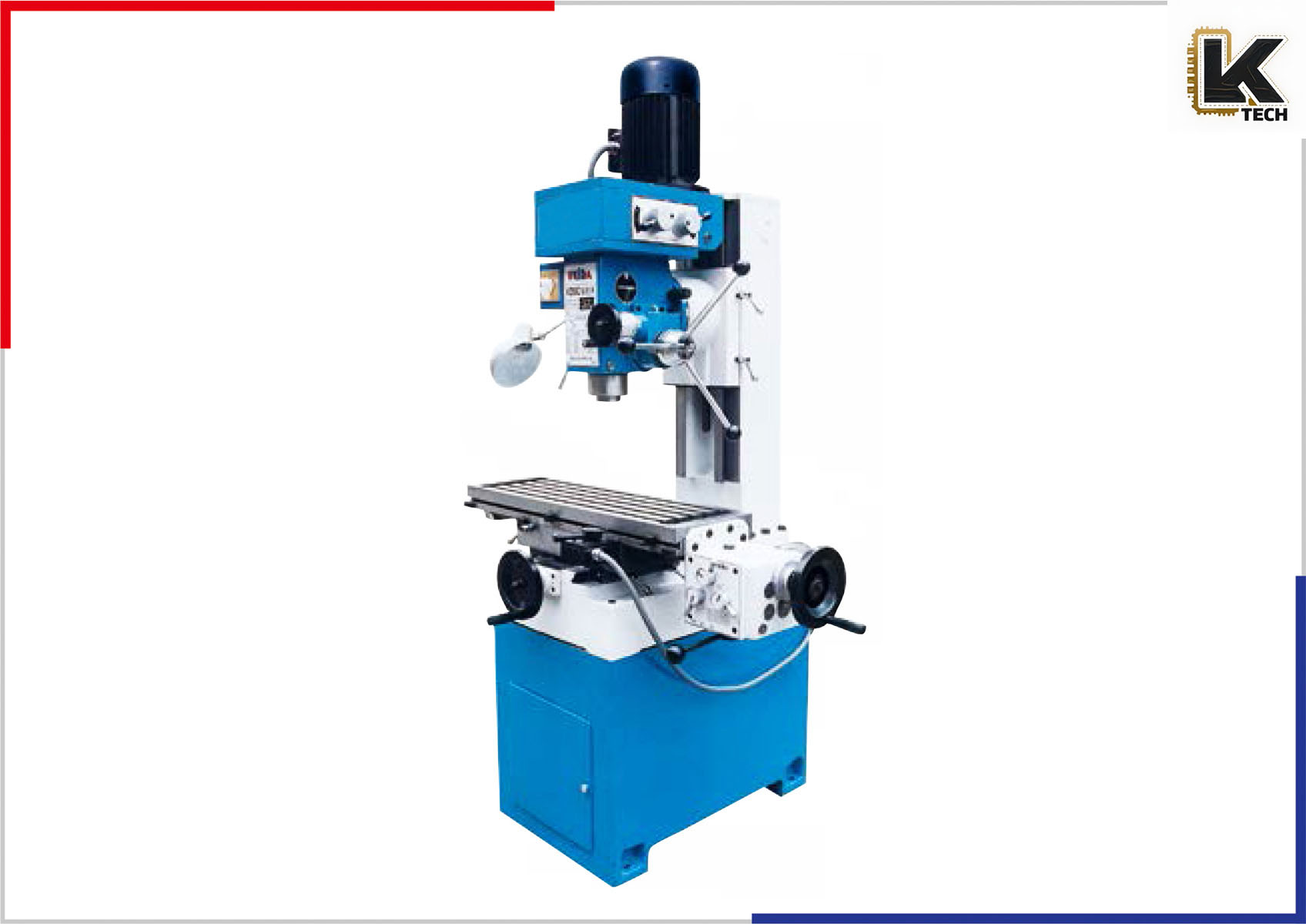

The Universal Milling and Drilling Machine is an essential piece of equipment for metalworking, designed to produce a broad range of mechanical components and precision parts. Ideal for both small and large workshops, this versatile machine is capable of executing tasks such as drilling, milling, tapping, and even contouring complex shapes, making it indispensable in a variety of industries, including automotive, aerospace, manufacturing, and engineering.

Key Features

The Universal Milling and Drilling Machine comes loaded with features that enhance its usability and efficiency:

- Multi-Functionality: The machine can perform various operations including drilling, milling, and reaming, making it suitable for diverse applications.

- Adjustable Speeds: The spindle speed can be adjusted to accommodate various materials and processes, ensuring optimal performance.

- Precision Engineering: With high levels of accuracy, this machine guarantees precise handling of various tasks – from delicate drilling to heavy milling.

- Robust Construction: Designed for durability, the structure of the machine is built to withstand the rigors of daily use in industrial settings.

Specifications Overview

Depending on the model, such as XZ6350B, XZ6350G, and others, the specifications might differ slightly. However, the following features are generally common across various variants:

Table Size and Travel

- Table Size: Models like the XZ6350B offer a table size of 1120mm x 260mm, providing ample space for larger workpieces.

- Table Travel: Depending on the model, the table travel can range from 600mm to 730mm, allowing operators to handle larger components effortlessly.

Drilling and Milling Capacity

- Max. Drilling Load: Each variant supports different maximum drilling loads, with models accommodating loads up to 300kg.

- Max. Drilling Diameter: Many machines can handle a drilling diameter suited for cast iron and steel, ranging from 20mm to 50mm.

- Max. Vertical Milling Diameter: Precision milling can be achieved with a maximum diameter of up to 32mm.

Spindle Features

- Spindle Speed Range: Depending on the model, spindle speed ranges can vary; for example, 90-2000 revolutions per minute (rpm) for standard operations and up to 3000 rpm for more advanced industrial tasks.

- Spindle Motor Power: Models feature spindle motor power ranging from 0.85kW to 2.2kW, optimized for high-performance applications.

Usability and Operation

The machine operates with user-friendly controls, making it accessible even for operators who are new to milling and drilling techniques. Key operational aspects include:

- Electric Control Panel: Most models include an electric control panel with digital displays for ease of use.

- Manual and Automatic Feed Settings: Users can choose between manual operations for precision tasks or automatic feeding for larger production runs.

- Safety Features: Equipped with various safety mechanisms, including emergency stop buttons and protective covers, ensuring a safe working environment.

Applications

The Universal Milling and Drilling Machine is versatile, making it ideal for numerous applications:

- Manufacturing Parts: Widely used in the manufacture of components such as brackets, chassis, and flanges.

- Tool and Die Work: Essential in creating tools, dies, and molds that are used in more advanced manufacturing processes.

- Prototype Development: Ideal for quick prototyping, allowing engineers to produce samples and test designs before mass production.

Maintenance and Support

To ensure longevity and optimal performance of the Universal Milling and Drilling Machine, regular maintenance is encouraged. Key maintenance tips include:

- Regular Lubrication: Keep all moving parts lubricated to prevent wear and ensure smooth operation.

- Periodic Cleaning: Clean the machine regularly to remove metal shavings, dust, and other debris that may accumulate during operation.

- Check Alignment: Regularly check and adjust the alignment of the spindle and table to maintain precision.

Conclusion

The Universal Milling and Drilling Machine serves as a vital asset in machining processes across various industries. Its robust build, combined with versatile functionality and precision capabilities, positions it as a must-have for any serious workshop. Investing in this machinery guarantees enhanced productivity and workflow efficiency, making any fabrication project seamless and professional.

Technical Specifications of Various Models

| Parameter | Units | XZ5150 |

|---|---|---|

| Table size | mm | 1220 × 360 |

| Table travel | mm | 600 × 360 |

| Spindle taper | mm | ISO40 |

| Distance from spindle nose to table surface | mm | 120–620 |

| Max. drilling diameter | mm | 50 |

| Max. end milling width | mm | 125 |

| Max. vertical milling diameter | mm | 32 |

| Spindle speed range | rpm | 94–2256 (16) |

| Automatic spindle feed speed | mm/rev | 0.1, 0.15, 0.3 |

| Overall dimension | mm | 1730 × 1730 × 2300 |

| Spindle motor power | kW | 1.5/2.4 |

| Machine weight | kg | 1750 |

| Parameter | Specification(X6432) |

|---|---|

| Table size | 1320 × 320 mm |

| Table travel | 1000 × 300 mm (manual) |

| Number/Width/Distance of T-slot | 5–14–63 mm |

| Max. table load | 300 kg |

| Spindle taper | ISO40 |

| Distance between spindle axis and table surface | 0–420 mm |

| Distance between spindle axis and ram surface | 180–600 mm |

| Spindle speed range (steps) | 45–1660 rpm (V), 40–1300 rpm (H) |

| Table power feed speed range in longitudinal | 20–360 mm/min (X/Y 8 steps), 422 mm/min (Z) |

| Ram travel | 360° |

| Spindle motor power | 3 kW (V/H) |

| Overall dimension (L × W × H) | 2020 × 1710 × 1994 mm |

| Machine weight | 2100 kg |

| Parameter | Units | Specification(XW5032C) |

|---|---|---|

| Table size | mm | 1320 × 320 |

| Table travel | mm | 1000 × 300 (manual) |

| Number/Width/Distance of T-slot | mm | 5–14–63 |

| Max. table load | kg | 300 |

| Spindle taper | ISO50 | |

| Distance from spindle nose to table surface | mm | 35–435 |

| Distance from spindle axis to vertical guideway | mm | 360 |

| Spindle speed range | rpm | 58–1710 |

| Spindle motor power | kW | 4 |

| Spindle travel | mm | 70 |

| Overall dimension (L × W × H) | mm | 2020 × 1820 × 1880 |

| Machine weight | kg | 2300 |

| Parameter | Units | X6336A | X6336 |

|---|---|---|---|

| Table size (L×W) | mm | 1650 × 360 | 1650 × 360 |

| Number/Width/Distance of T-slot | mm | 3-14-95 | 3-14-95 |

| Max. table load | kg | 300 | 300 |

| Table travel | mm | 1300/320 | 1300/300/420 |

| Spindle taper | ISO40 (V)/ISO40 (H) | ISO40 (V)/ISO50 (H) | |

| Spindle speed | rpm | 58-3000 (V)/58-1800 (H) | 58-3000/10 Steps (V) 58-1800/12 Steps (H) |

| Quill travel | mm | 150 | 150 |

| Motor power | kW | 5.5 (V/H) | 3.7 (V)/4.0 (H) |

| Servo motor torque | N·m | 11.5 | - |

| Overall size (L×W×H) | mm | 2070 × 1930 × 2250 | 1890 × 1920 × 2330 |

| Net weight | kg | 2800 | 2200 |

| Parameter | XQ6226B | XQ6226A |

|---|---|---|

| Table size | 1120 × 260 mm | 1120 × 260 mm |

| Table travel | 600 × 270 mm | 600 × 270 mm |

| Ram travel | 60–550 mm | 60–550 mm |

| Max. table load | 250 kg | 250 kg |

| Spindle taper | ISO40 | ISO40 |

| Distance from spindle nose to table surface | 80–480 mm | 80–480 mm |

| Max. end milling width | 125 mm | 125 mm |

| Max. vertical milling diameter | 25 mm | 25 mm |

| Spindle speed range | 45–1660 rpm | 45–1660 rpm |

| Swivel angle of swivel head | 360° | 360° |

| Overall dimension (L×W×H) | 1655 × 1500 × 1730 mm | 1655 × 1500 × 1730 mm |

| Spindle motor power | 2.2 kW | 2.2 kW |

| Machine weight | 1480 kg | 1400 kg |

| Parameter | Units | XW6032B | XW6136 |

|---|---|---|---|

| Table size (L×W) | mm | 1320 × 320 | 1650 × 360 |

| Table travel | mm | 1000 × 300 (manual) | 1000 × 300 |

| Number/Width/Distance of T-slot | mm | 5–14–63 | 3–14–95 |

| Spindle taper | - | ISO50 (H)/ISO40 (V) | ISO50 (H)/ISO40 (V) |

| Distance from spindle axis to table surface | mm | 0–400 | 0–400 |

| Distance between spindle axis and boom | mm | 175 | 175 |

| Spindle speed range | rpm | 58–1800 | 58–1800 (12 steps) |

| Spindle motor power | kW | 4 | 4 |

| Overall dimension (L×W×H) | mm | 2070 × 2020 × 1850 | 2100 × 2550 × 2100 |

| Machine weight | kg | 2200 | 2300 |

| Parameter | X6328B | X6332Z |

|---|---|---|

| Table size (L×W) | 1120 × 260 mm | 1320 × 320 mm |

| Table travel | 600 × 270 × 300 mm | 1000 × 300 mm |

| Number/Width/Distance of T-slot | 3–14–63 mm | 5–14–63 mm |

| Max. table load | 250 kg | 300 kg |

| Distance from spindle nose to table surface | 100–400 mm | 180–580 mm |

| Distance from spindle axis to column surface | 50–550 mm | 200–780 mm |

| Spindle travel | 127 mm | 120 mm |

| Spindle taper (V/H) | ISO40 | ISO40 |

| Spindle speed range | 65–4510 rpm (V) 38–1310 rpm (H) | 90–2000 rpm (V) 38–1310 rpm (H) |

| Spindle motor power | 2.2 kW | 2.2 kW |

| Overall dimension (L×W×H) | 1710 × 1480 × 2100 mm | 1710 × 1720 × 2330 mm |

| Machine weight | 1350 kg | 2000 kg |

| Parameter | XZ6326B | XZ6350ZS |

|---|---|---|

| Table size (L×W) | 1120 × 260 mm | 1270 × 320 mm |

| Table travel | 600 × 270 mm | 730 × 270 mm |

| Max. table load | 200 kg | 300 kg |

| Max. drilling diameter | ♦ 30 mm (cast iron, manual) ♦ 20 mm (steel, manual) | ♦ 50 mm (cast iron, manual) ♦ 35 mm (steel, manual) |

| Distance from spindle nose to table surface | 115–430 mm | 120–500 mm |

| Spindle travel | 120 mm | 120 mm |

| Max. end milling width | 125 mm | 125 mm |

| Spindle speed range | 67–2010 rpm (V) 40–1300 rpm (H) | 90–2000 rpm (V) 60–1350 rpm (H) |

| Spindle motor power | 1.5/2.2/2.2 kW | 2.2 kW |

| Overall dimension (L×W×H) | 1580 × 1450 × 2150 mm | 1680 × 1640 × 2200 mm |

| Machine weight | 1350 kg | 1650 kg |

| Parameter | XZ7550CW | XZ500C |

|---|---|---|

| Table size (L×W) | 800 × 240 mm | 800 × 240 mm |

| Table travel | 400 × 200 mm | 400 × 215 mm |

| Max. drilling diameter | 30 mm | 30 mm |

| Distance from spindle nose to table surface | 70–420 mm | 50–410 mm |

| Max. vertical milling diameter | 25 mm | 25 mm |

| Spindle travel | 120 mm | 120 mm |

| Max. end milling width | 100 mm | 100 mm |

| Spindle speed range | 115–1750 rpm | 115–1750 rpm |

| Spindle motor power | 0.85/1.5 kW (V) 1.5 kW (H) | 0.85/1.5 kW |

| Overall dimension (L×W×H) | 1290 × 1140 × 2100 mm | 1270 × 950 × 1800 mm |

| Machine weight | 800 kg | 500 kg |

| Parameter | XZ6350ZB | XZ6350G | XZ6350B |

|---|---|---|---|

| Table size (L×W) | 1120 × 260 mm | 1120 × 260 mm | 1120 × 260 mm |

| Table travel | 600 × 270 mm | 600 × 300 mm | 600 × 270 mm |

| Max. drilling load | 200 kg | 200 kg | 200 kg |

| Max. drilling diameter | ♦ 30 mm (cast iron, manual) ♦ 20 mm (steel, manual) | ♦ 30 mm (cast iron, manual) ♦ 20 mm (steel, manual) | ♦ 30 mm (cast iron, manual) ♦ 20 mm (steel, manual) |

| Distance from spindle nose to table surface | 100–400 mm | 100–400 mm | 100–400 mm |

| Spindle travel | 120 mm | 120 mm | 120 mm |

| Max. vertical milling diameter | 25 mm | 25 mm | 25 mm |

| Max. end milling width | - | 100 mm | 100 mm |

| Spindle speed range | 90–2000 rpm (V) 40–1300 rpm (H) | 115–1750 rpm (V) 40–1300 rpm (H) | 115–1750 rpm (V) 40–1300 rpm (H) |

| Spindle motor power | 2.2 kW | 0.85/1.5 kW (V) 2.2 kW (H) | 0.85/1.5 kW (V) 2.2 kW (H) |

| Overall dimension (L×W×H) | 1520 × 1290 × 2150 mm | 1580 × 1330 × 2250 mm | 1655 × 1450 × 2150 mm |

| Machine weight | 1400 kg | 1350 kg | 1500 kg |

These specifications serve as a guide to help prospective buyers assess the best model that suits their operational needs and budgets. Thus, the Universal Milling and Drilling Machine remains a cornerstone of contemporary manufacturing and machining processes.

Categories

Automation conneting equipment auxiliary machine Foam machinery Mattress machines Metal processing machine Plywood working machine Solid wood working machineTags