3D Brush Sander (FHDR1300 & FHDR1000)

3D Brush Sander (FHDR1300 & FHDR1000)

Introduction

Welcome to the future of woodworking excellence with the state-of-the-art 3D Brush Sander, specifically engineered for furniture manufacturers, woodworking artisans, and industrial production facilities that prioritize quality finishes. Combining precision, efficacy, and advanced technology, the 3D Brush Sander represents a significant advancement in surface finishing processes. Available in two variants—the FHDR1300 and FHDR1000—this versatile sander meets diverse operational needs while maintaining robust performance.

Overview

The 3D Brush Sander boasts an array of features designed to deliver impeccable results with each use. Unlike conventional sanders that often leave uneven finishes, or require meticulous manual work, this sander streamlines your workflow. It’s specifically designed to handle various materials—including wood, composite products, and decorative surfaces—making it the perfect ally in your workshop.

Key Features

- Work Width & Length Specifications

- FHDR1300: Maximum work width of 1300 mm, and minimum work length of 460 mm.

- FHDR1000: Maximum work width of 1000 mm, with a minimum work length of 320 mm. These dimensions provide flexibility in accommodating different project sizes, ensuring that the sander can handle both large and small items seamlessly.

- Versatile Working Thickness

- Both models can efficiently sand materials with a thickness ranging from 3 mm to 120 mm. This capability enables operators to work on various substrates while achieving optimal finishing results.

- Multi-Unit Configuration

- FHDR1300: Features 2 units of the first sanding unit, 6 units of successive secondary units, and 1 unit of a third unit.

- FHDR1000: Offers a similar configuration with a slight variation in the number of secondary units (5). This multi-faceted design enhances efficiency by allowing multiple sanding stages to occur simultaneously.

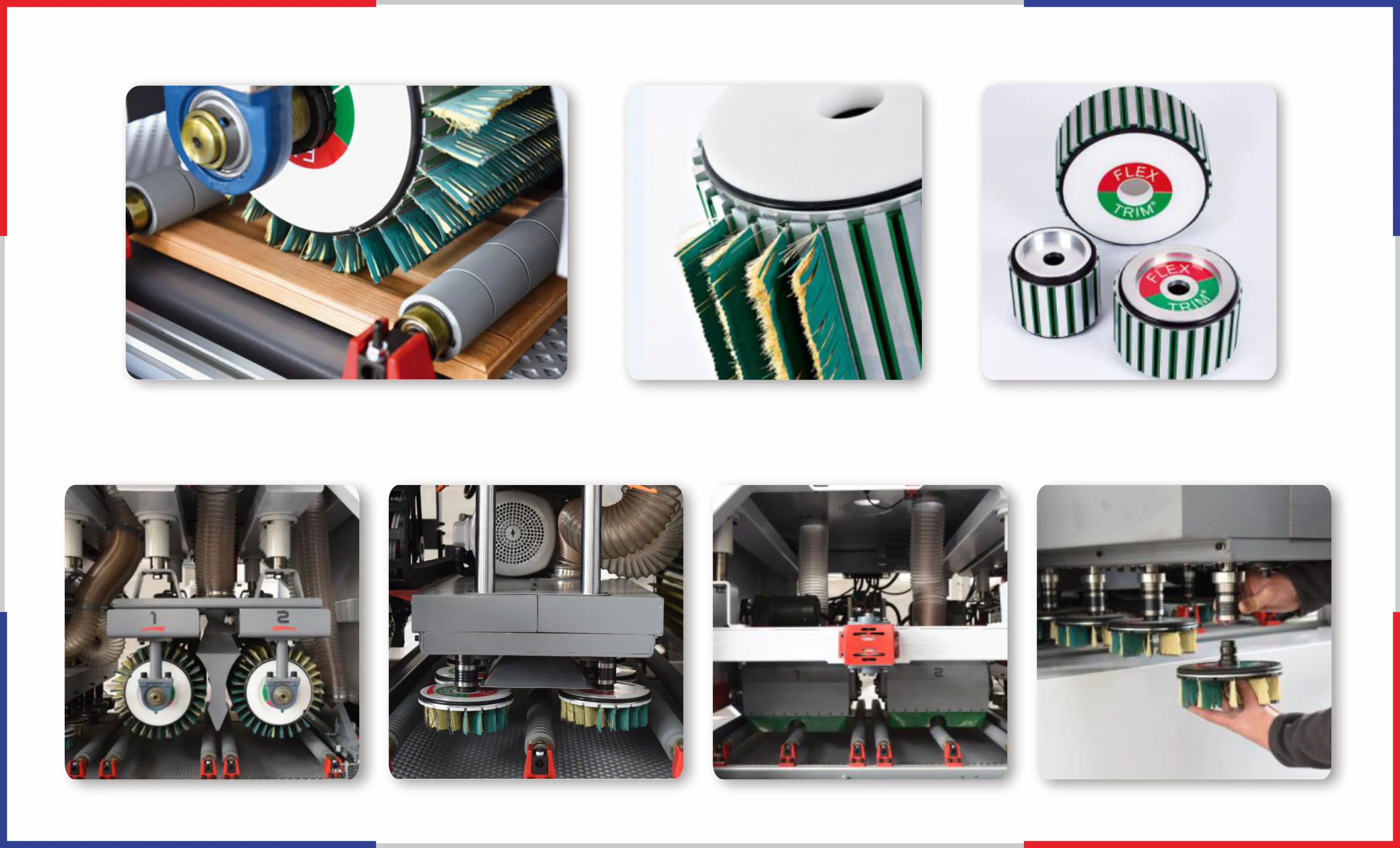

- Innovative Brush Design

- The sander is equipped with specialized brushes with varying diameters—175 mm for the primary brushes and 306 mm or 336 mm for secondary brushes. This innovative design allows for detailed finishing and the capacity to achieve different textures, ideal for complex woodworking patterns.

- Advanced Air Pressure System

- Operating under a controlled air pressure level of 0.6 Mpa ensures the sander maintains effective operation and consistent sanding quality. This feature is critical for an efficient and powerful sanding process.

- Customizable Feeding Speed

- Adjustable feeding speeds between 3 to 17 meters per minute cater to different materials and thicknesses, allowing for greater flexibility based on specific project needs.

- Total Power Output

- The FHDR1300 model has a power output of 20 kW while the FHDR1000 comes with an output of 11 kW. This powerful performance facilitates a faster and more effective sanding process, giving woodworkers a competitive edge.

- Compact Dimensions

- Overall dimensions:

- FHDR1300: 2230 mm x 4650 mm x 2135 mm

- FHDR1000: 1930 mm x 4000 mm x 2100 mm The compact design allows easy integration into existing workshop spaces without compromising operational efficiency.

- Overall dimensions:

- User-Friendly Interface

- An intuitive control panel enhances the overall user experience. Operators can easily navigate settings and make adjustments without requiring extensive technical knowledge.

- Durability and Reliability

- Constructed from high-quality materials, the 3D Brush Sander promises durability that withstands the rigors of industrial application, ensuring longevity and minimal maintenance needs.

| No. | Item | FHDR1300 | FHDR1000 |

|---|---|---|---|

| 1 | Work width MAX. (mm) | 1300 | 1000 |

| 2 | Work length MIN. (mm) | 460 | 320 |

| 3 | Working thickness (mm) | 3-120 | 3-120 |

| 4 | Number of 1st unit (piece) | 2+2 | 2+2 |

| 5 | Number of 2nd unit (piece) | 6+6 | 5+5 |

| 6 | Number of 3rd unit (piece) | 1+1 | 1+1 |

| 7 | Diameter of 1st unit (piece) | Φ175 | Φ175 |

| 8 | Diameter of 2nd/3rd unit (piece) | Φ306/φ336/φ356 | Φ306/φ336/φ356 |

| 9 | Air pressure (Mpa) | 0.6 | 0.6 |

| 10 | Feeding Speed (m/min) | 3-17 | 3-17 |

| 11 | Total Power (kw) | 20 | 11 |

| 12 | Overall Dimension (mm) | 2230×4650×2135 | 1930×4000×2100 |

| 13 | Platform height (mm) | 875 | 875 |

| 14 | Weight (kg) | 5800 | 4700 |

| 15 | Voltage (at your choice) | 380V/50HZ/3PH | 380V/50HZ/3PH |

Benefits of Using the 3D Brush Sander

The implementation of the 3D Brush Sander into your production line offers numerous advantages:

- Enhanced Quality: Achieve top-tier surface finishes that meet high standards, significantly reducing the need for secondary sanding processes.

- Time Efficiency: Fast processing time allows you to complete projects quicker, enabling you to take on larger volumes of work.

- Reduced Labor Costs: Automating the sanding process with this advanced machine minimizes manual labor, allowing your skilled technicians to concentrate on more complex aspects of production.

- Versatility: Capable of handling a variety of materials and thicknesses expands your workshop’s service offerings, catering to diverse customer needs.

- Eco-friendly Design: The controlled air pressure and efficiency reduce waste, ensuring that operations are environmentally friendly.

Ideal Applications

The 3D Brush Sander is suitable for a broad range of applications, including:

- Furniture Manufacturing: For assembling various types of furniture pieces from tables to cabinets, ensuring precision and quality.

- Architectural Millwork: Perfect for detailed finishing work required in window frames, doors, and custom design elements.

- Composite Materials: Works effectively with MDF, particle board, and engineered wood products for a flawless surface treatment.

- Artistic Woodworking: Ideal for artisans creating bespoke wood items that demand a high-quality finish with intricate patterns.

Conclusion

In today’s fast-paced manufacturing environment, the 3D Brush Sander emerges as an indispensable tool in both small shops and large-scale production lines. With its groundbreaking technology, customizable speed settings, and the ability to produce impeccable finishes, the 3D Brush Sander redefines efficiency and perfection in woodworking.

Embrace the future of surface finishing and elevate your workshop’s capabilities with either the FHDR1300 or FHDR1000 model. Discover how innovation meets your woodworking needs—delivering products that don’t just meet expectations but surpass them. Invest in the 3D Brush Sander today, and let your craftsmanship shine with enhanced precision and ease!

Categories

Automation conneting equipment auxiliary machine Foam machinery Mattress machines Metal processing machine Plywood working machine Solid wood working machineTags