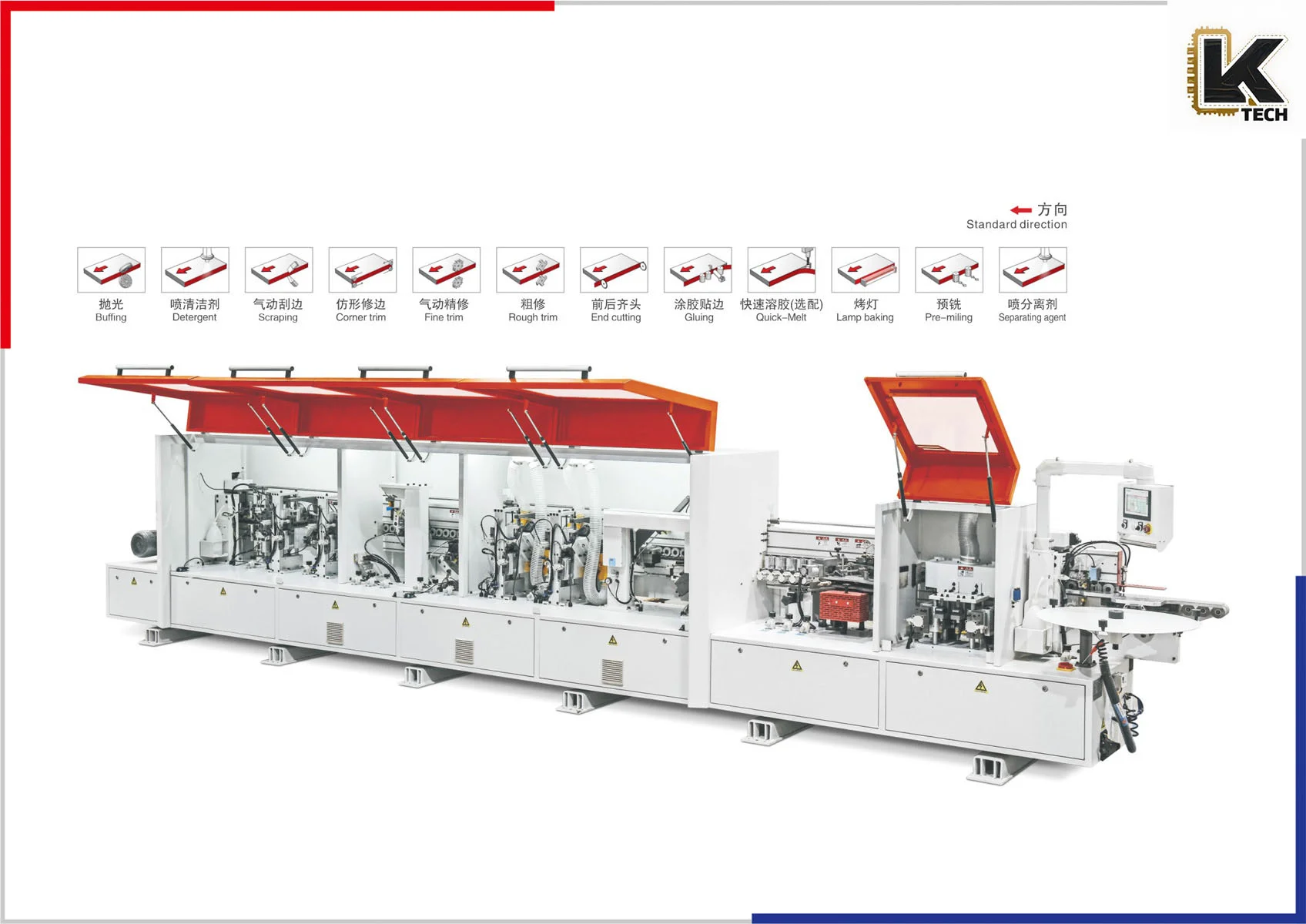

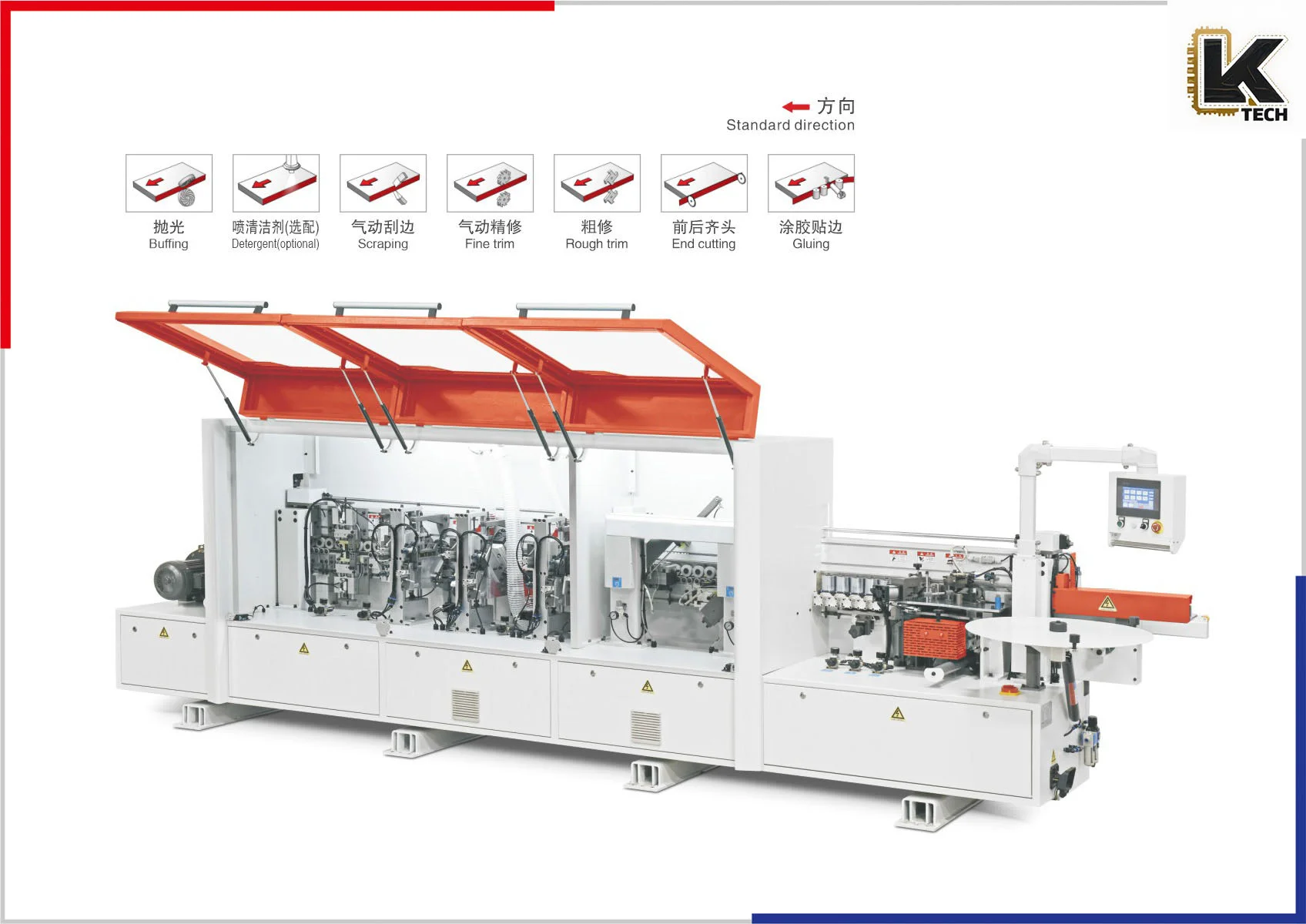

Automatic Edge Banding Machine Series

The Automatic Edge Banding Machine is a highly advanced woodworking machine designed for the woodworking industry, specifically for efficiently and accurately applying edge banding to wood panels, furniture, and other wooden products. Based on the provided images and technical specifications, this product offers a variety of features and configurations that meet diverse production needs, significantly improving production efficiency and product quality. Below is a detailed introduction to this equipment.

Equipment Overview

The main function of the automatic edge banding machine is to apply edge materials such as PVC, wood veneer, or other synthetic materials to the edges of wood products. This machine can complete the edge banding process in a short time, ensuring smooth and flawless edges. The machine is designed with ease of operation and maintenance in mind, making it suitable for mass production requirements.

Key Features

- Multi-function Processing Capability

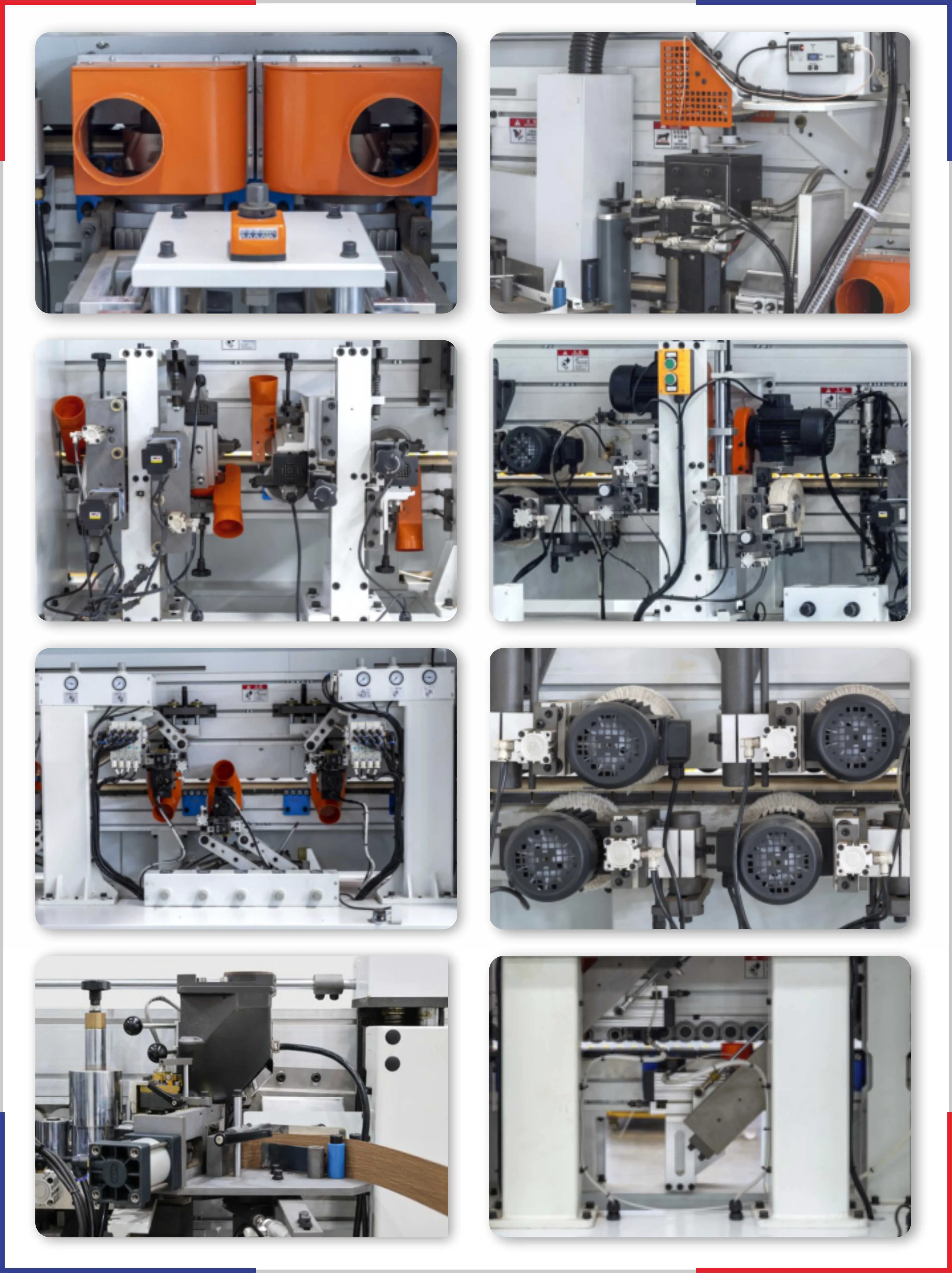

The automatic edge banding machine integrates multiple functional modules, allowing for a series of operations from rough trimming, fine trimming, and edge scraping to final gluing. As shown in the provided images, the machine can perform the following steps:

- Buffing: The machine polishes the edges of the panels to ensure a smooth and polished finish.

- Detergent (optional): An optional detergent cleaning process for removing dirt and oils from the edges of the material.

- Scraping: The machine scrapes off any excess glue or material, ensuring clean, precise edges.

- Fine Trim: A finer trimming process to refine the edges for a perfect fit.

- Rough Trim: Trims the panel edges roughly before finer finishing.

- End Cutting: The final cutting of panel edges to the correct length.

- Gluing: The final stage where adhesive is applied to the edge banding for a secure bond.

- User-friendly Design The machine features a well-thought-out design, ensuring easy access for operators to manage the functions and maintenance tasks. The control interface is clearly visible and accessible, providing real-time machine data and adjustments for smooth operation. The provided images also show how various parts of the machine are organized for easy adjustments and repairs.

- High Precision and Efficiency With advanced automation, the machine is capable of producing consistent edge banding results with minimal human intervention. The use of high-quality motors and pneumatic systems allows the machine to operate with great precision, ensuring that the edge banding is uniform across all panels. The feeding speed is adjustable between 15 to 23 meters per minute, depending on the production requirements, providing flexibility and efficiency for various batch sizes.

- Robust Construction The machine is built with high-strength materials, ensuring durability and long-term reliability. The sturdy construction reduces vibrations, improving both the precision and the longevity of the machine. The compact design also helps save valuable floor space in workshops, contributing to a more organized workspace.

- Customization Options The machine comes with multiple configuration options to suit different production needs. As seen in the technical specifications, the machine can handle different wood panel sizes, tape thicknesses, and feeding speeds. These customizable settings ensure that the machine can handle a wide variety of materials and production scenarios, allowing businesses to meet diverse customer demands.

Technical Specifications

The automatic edge banding machine is available in several models, each offering different power and size configurations. Below are the specifications for different models:

| No. | Item | TEM-680 | TEM-681 | TEM-682 | TEM-683 |

|---|---|---|---|---|---|

| 1 | Length | Min: 150 mm | Min: 150 mm | Min: 150 mm | Min: 150 mm |

| 2 | Width | Min: 80 mm | Min: 80 mm | Min: 80 mm | Min: 80 mm |

| 3 | Thickness | 10-60 mm | 10-60 mm | 10-60 mm | 10-60 mm |

| 4 | Tape width | 12-65 mm | 12-65 mm | 12-65 mm | 12-65 mm |

| 5 | Tape thickness | 0.4-3 mm | 0.4-3 mm | 0.4-3 mm | 0.4-3 mm |

| 6 | Feeding speed | 15-23 m/min | 15-23 m/min | 15-23 m/min | 15-23 m/min |

| 7 | Minimum wood plate size | 300×80 mm 150×150 mm | 300×80 mm 150×150 mm | 300×80 mm 150×150 mm | 300×80 mm 150×150 mm |

| 8 | Voltage | 380V/50Hz | 380V/50Hz | 380V/50Hz | 380V/50Hz |

| 9 | Total power | 11 kW | 14 kW | 13 kW | 16.5 kW |

| 10 | Air pressure | 0.6 MPa | 0.6 MPa | 0.6 MPa | 0.6 MPa |

| 11 | Machine size | 5050×950×1550 mm | 5780×950×1550 mm | 6150×950×1550 mm | 7310×950×1620 mm |

These models vary in total power, machine size, and other technical aspects, allowing customers to choose the appropriate model based on their production scale and requirements.

Applications

The automatic edge banding machine is widely used in industries that manufacture furniture, kitchen cabinets, office furniture, and other wood products that require edge banding. It is suitable for both small-scale workshops and large industrial production lines. The high speed, precision, and automation features make this machine an excellent choice for businesses looking to enhance their production efficiency and product quality.

Conclusion

The Automatic Edge Banding Machine is an essential piece of equipment for modern woodworking operations. With its robust construction, multiple functions, and high precision, it provides businesses with a reliable solution for edge banding. The customizable features and flexible configurations ensure that it can meet a wide range of production needs, making it a versatile choice for both small and large manufacturers in the woodworking industry.

Categories

Automation conneting equipment auxiliary machine Foam machinery Mattress machines Metal processing machine Plywood working machine Solid wood working machineTags