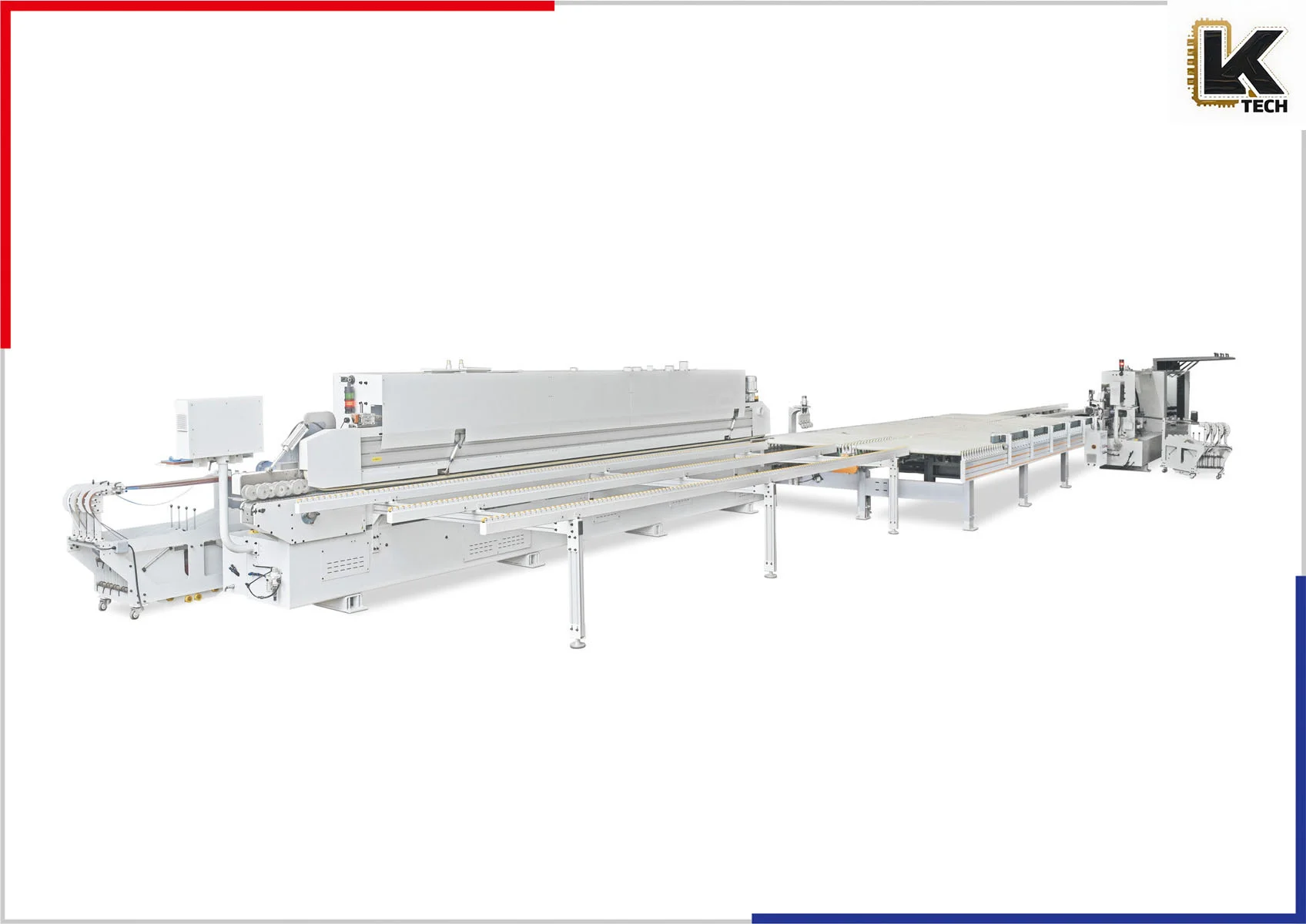

Automatic Servo Control Edge Banding Machine with Left and Right-Hand Connection

Automatic Servo Control Edge Banding Machine with Left and Right-Hand Connection

In the ever-evolving world of woodworking, ensuring precision and efficiency in manufacturing processes is crucial for achieving outstanding results. The Automatic Servo Control Edge Banding Machine, featuring left and right-hand connection capabilities, emerges as a transformative innovation tailored to meet the high demands of modern furniture production. This sophisticated machine combines cutting-edge technology with intelligent design to streamline operations, making it an indispensable asset for large-scale manufacturing setups. Let us delve into the intricacies and advantages offered by this remarkable machine.

- Overview of the Machine:

- The Automatic Servo Control Edge Banding Machine is engineered to execute the process of covering the exposed edges of furniture panels with a thin strip called an edge band. This aesthetic enhancement not only improves the visual appeal of furniture but also increases its durability by protecting the edges from chipping and moisture ingress.

- Integrating both left and right-hand connections allows for unparalleled flexibility in operation, accommodating diverse production layouts and optimizing factory space utilization.

- Advanced Servo Control System:

- At the heart of the machine lies a sophisticated servo control system that ensures precise and adaptable motion control. This technology facilitates rapid adjustments in banding speed and pressure, allowing operators to tailor settings to the specific materials used, resulting in flawless edge banding.

- The use of servo motors enhances the positioning accuracy of components, ensuring consistent quality across batches by minimizing human error.

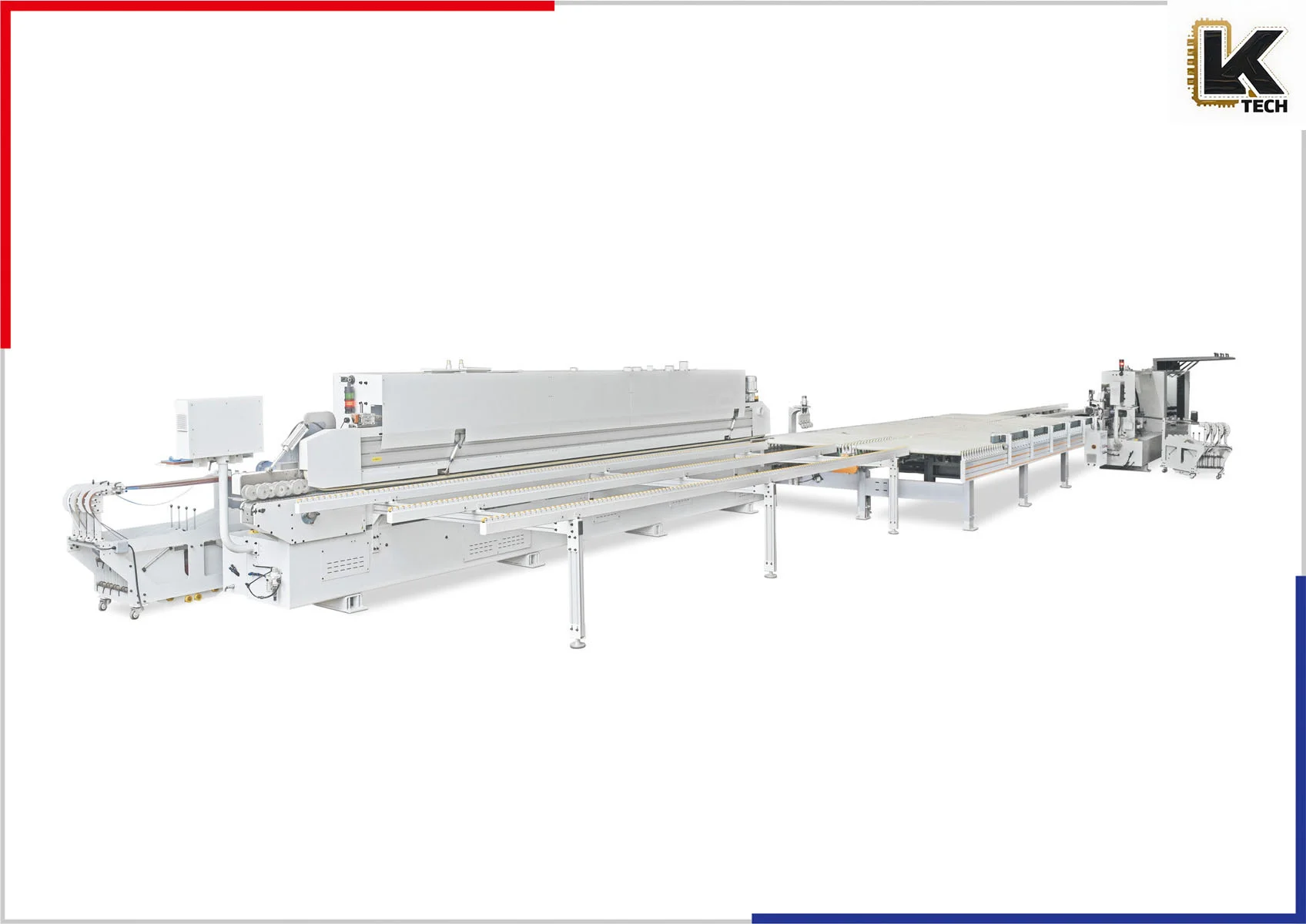

- Optimized Design and Construction:

- Crafted with precision engineering, the machine’s robust construction ensures stability during high-speed operations. The infrastructure is meticulously designed to withstand prolonged use, guaranteeing longevity and reliability.

- Ergonomics play a vital role in the setup, with user-friendly interfaces allowing operators to seamlessly control and monitor the machine’s functions. This intuitive design reduces the learning curve and enhances operational efficiency.

- Left and Right-Hand Connectivity:

- The ability to connect the machine both left and right expands its versatility, accommodating varying factory layouts. This design enables seamless integration into existing production lines, optimizing workflow without necessitating significant modifications.

- This connectivity feature is particularly advantageous in large-scale operations involving complex cabinetry and furniture designs, where strategic positioning and simultaneous dual-side operation can substantially reduce production time.

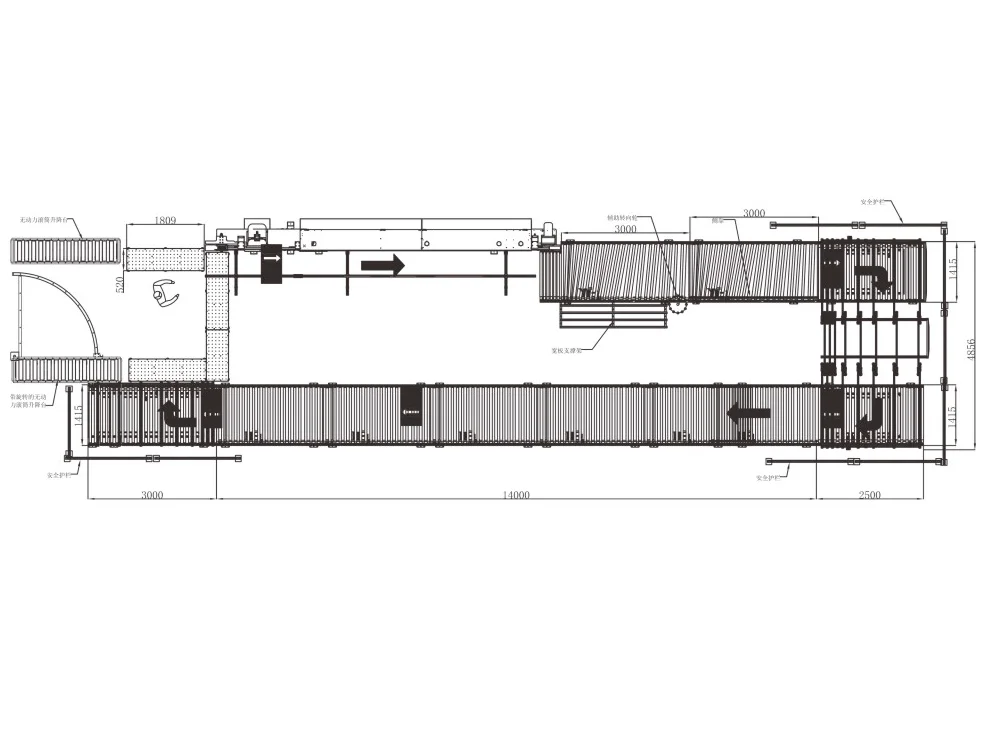

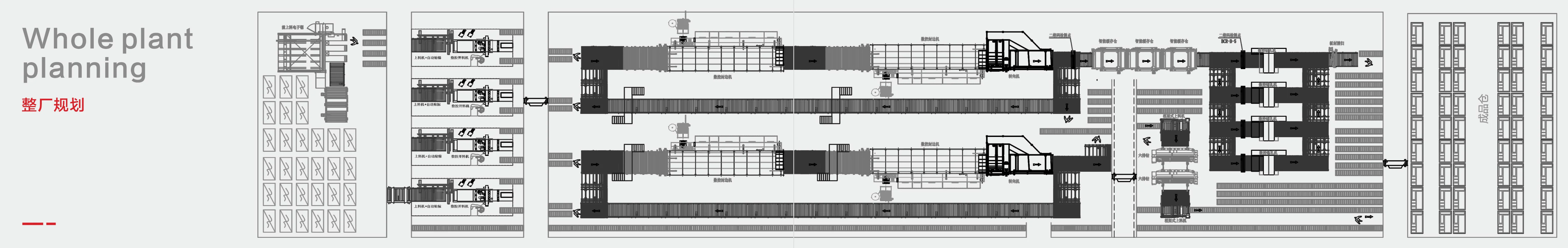

- Integration with Whole Plant Planning:

- The machine can be incorporated into whole plant planning, enhancing compatibility with advanced manufacturing setups. This integration ensures synchronized operations across all units, paving the way for efficient throughput and effective time management.

- Whole plant planning capabilities enable manufacturers to visualize, strategize, and implement production processes holistically, leading to increased productivity and reduced downtime.

- Energy Efficiency and Sustainable Operations:

- Embracing energy-efficient technologies, the machine minimizes power consumption without compromising performance. This characteristic not only reduces operational costs but also aligns with environmental sustainability goals.

- Advanced energy-saving modes and smart shutdown features contribute significantly to reducing the machine’s carbon footprint, making it suitable for environmentally conscious manufacturers.

- Enhanced Safety Features:

- Safety is incorporated as a fundamental aspect of the machine’s design, with comprehensive protective systems shielding operators from potential hazards. Emergency stop mechanisms and safety interlocks ensure immediate cessation in case of malfunction, safeguarding personnel and equipment alike.

- Continuous monitoring systems provide real-time feedback on the machine’s status, allowing prompt intervention and minimization of risks.

- Precision in Application:

- The machine excels in its ability to apply edge bands with unmatched precision. Equipped with state-of-the-art sensors and cutting tools, it adjusts for variations in panel thickness and edge material, resulting in seamless application even on intricate designs.

- Maintenance and Longevity:

- Minimal maintenance requirements and easy access to critical components make the machine both user-friendly and economical. Regular maintenance routines can be simplified, ensuring continued high performance without burdening operators.

- Benefits for Furniture Industry:

- In the competitive world of furniture manufacturing, the Automatic Servo Control Edge Banding Machine stands out as an investment yielding substantial returns. Through its ability to deliver consistent quality, manufacturers can uphold their reputation for producing top-tier products.

- Rapid adaptability to diverse furniture designs facilitates innovation, empowering manufacturers to swiftly respond to evolving consumer preferences while ensuring superior craftsmanship.

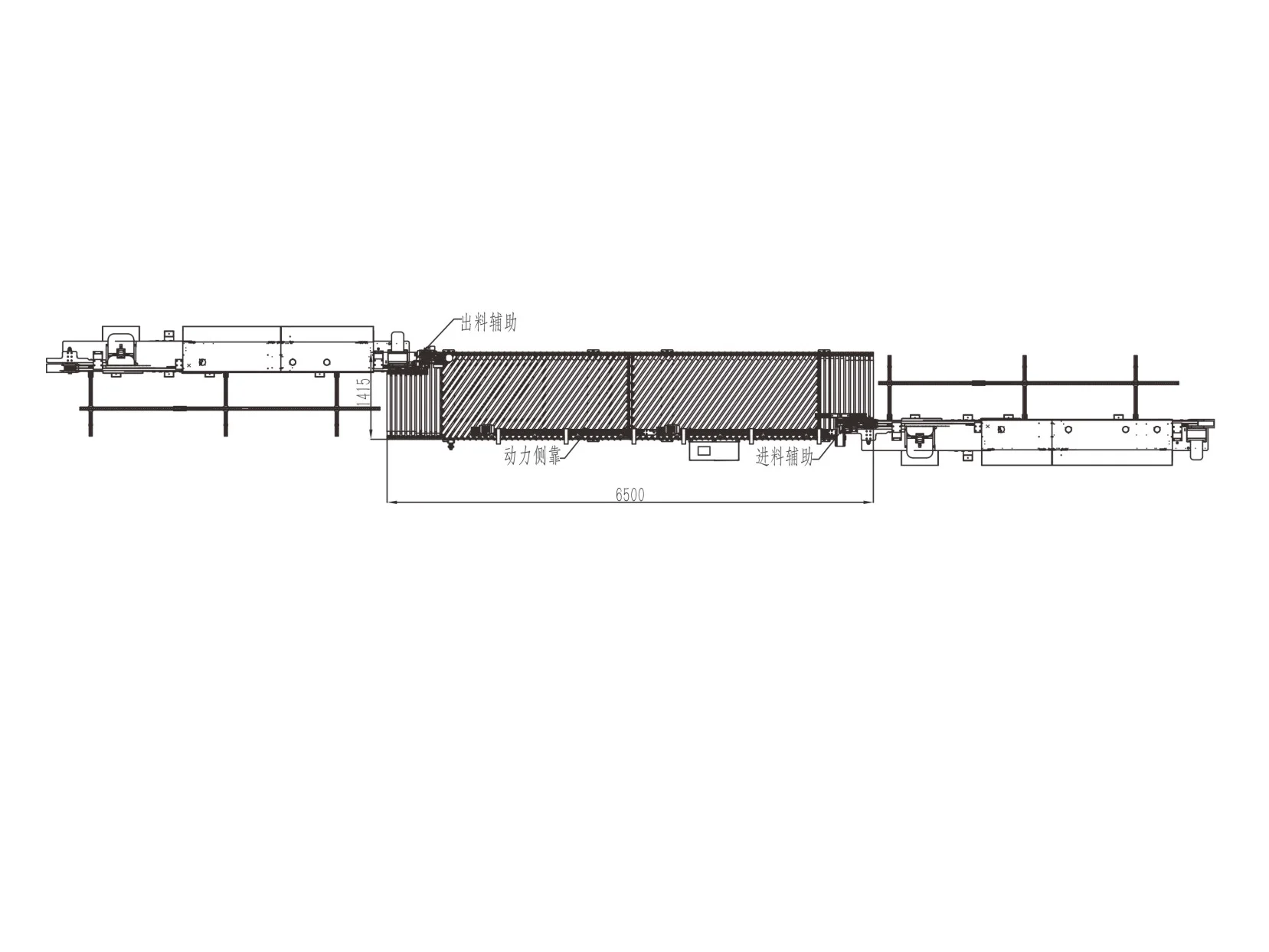

- Technical Specifications:

- Endowed with enhanced specifications, including customizable banding speeds, dynamic servo motor adjustments, and compatibility with varied band materials, the machine promises unparalleled versatility and adaptability.

- Its dimensions and configuration can be tailored based on specific factory requirements, ensuring seamless integration and maximized output.

- Concluding Insights:

- The Automatic Servo Control Edge Banding Machine, with its intelligent design, precision technology, and flexible connectivity, proves indispensable for manufacturers aspiring to revolutionize their production capabilities. Whether for traditional woodworking enterprises or innovative design firms, this machine is poised to transform edge banding operations into a seamless, efficient, and future-ready process.

- By integrating this machine into manufacturing lines, companies can upscale production, ensuring sustainable growth and establishing themselves as leaders in the furniture industry.

Overall, the Automatic Servo Control Edge Banding Machine is not merely an addition to a manufacturing setup; it represents a pivotal advancement in edge banding technology. With its unique features and substantial benefits, it is destined to be the cornerstone of modern furniture production.

Categories

Automation conneting equipment auxiliary machine Foam machinery Mattress machines Metal processing machine Plywood working machine Solid wood working machineTags