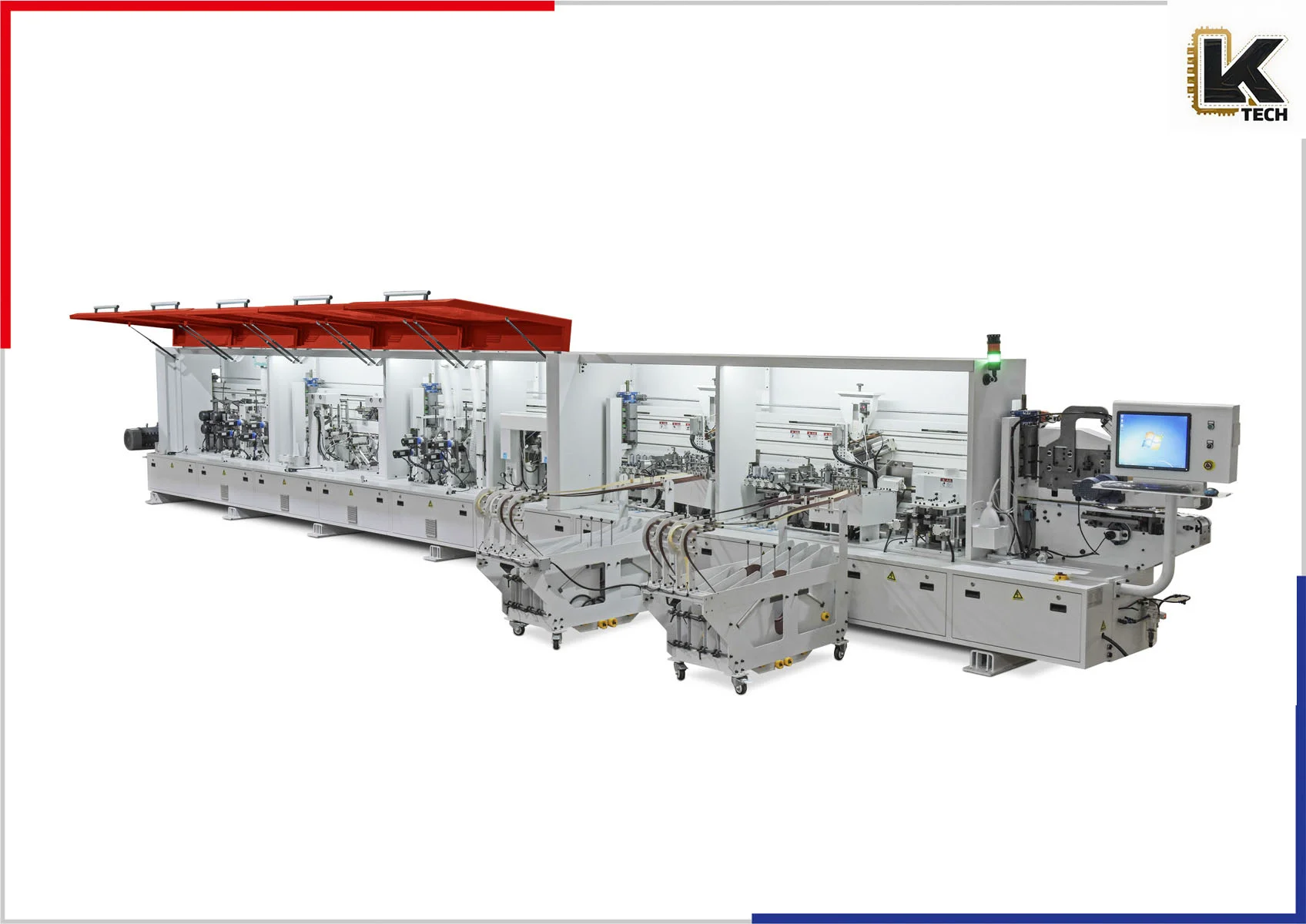

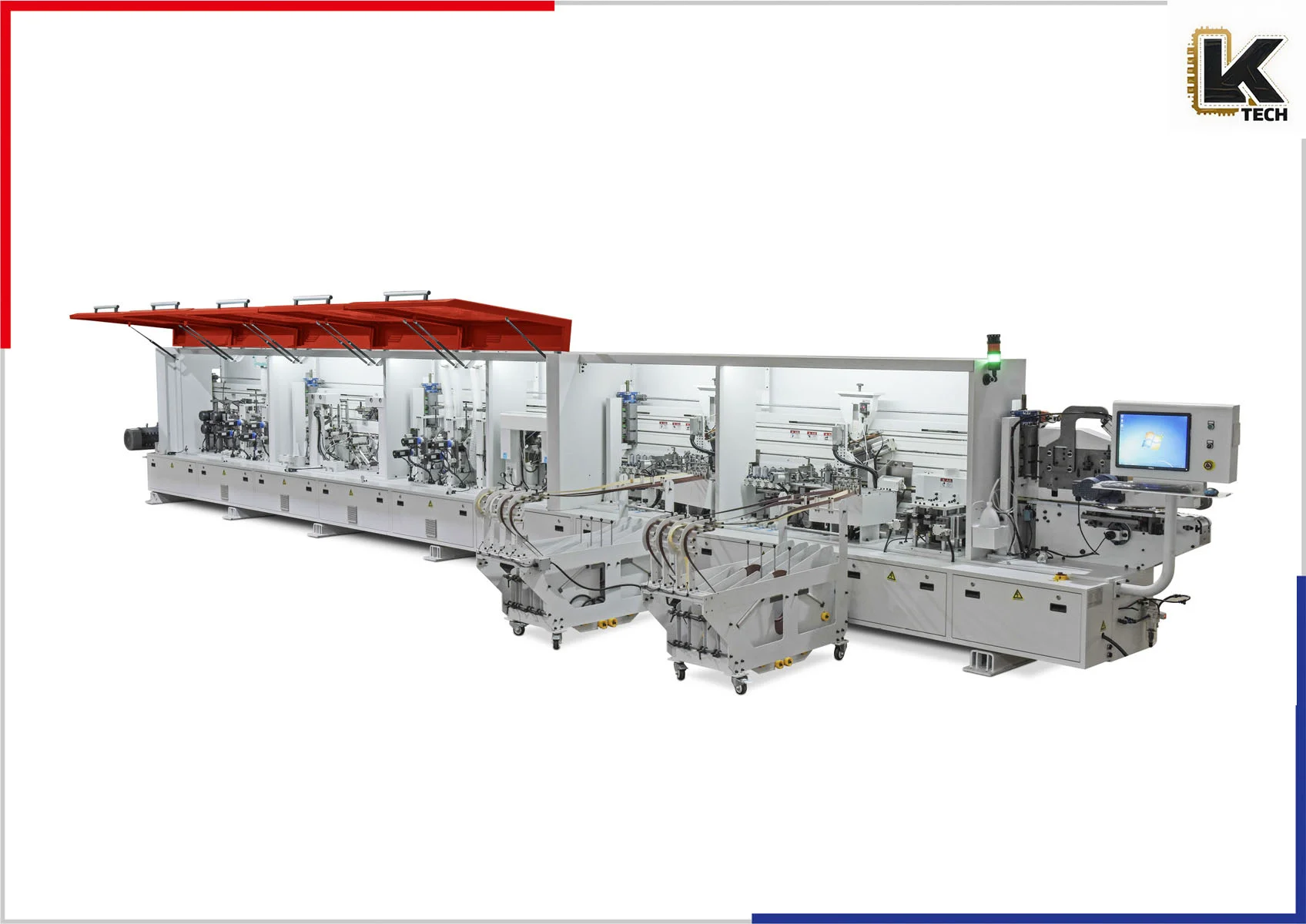

Automatic Servo Control Flexible Edge Banding Machine: Revolutionizing Panel Processing

In the world of modern woodworking and furniture manufacturing, precision and efficiency are key. The Automatic Servo Control Flexible Edge Banding Machine represents a quantum leap in edge banding technology, offering unparalleled versatility, accuracy, and speed. Designed to meet the demands of both small workshops and large-scale production facilities, this cutting-edge machine is engineered to deliver superior results consistently.

Overview and Design Philosophy

The Automatic Servo Control Flexible Edge Banding Machine is the epitome of advanced engineering combined with user-friendly functionality. Its robust design assures durability, while its sophisticated servo control system ensures precision in every operation. The machine comes equipped with a series of components that work harmoniously to transform raw panels into beautifully finished products, enhancing aesthetics and protecting panel edges from moisture and physical damage.

Technical Specifications

The machine is designed to handle a variety of edge banding materials, including PVC, ABS, acrylic, and wood veneer, catering to the diverse needs of different production environments. With a state-of-the-art servo control mechanism, it accurately regulates the application of edge banding across panels of varying thicknesses and dimensions. The touch-screen interface simplifies operation, allowing users to adjust settings effortlessly and monitor real-time production data.

Key Features

- Servo Control System: The inclusion of servo control technology guarantees precise adjustments and synchronization throughout the banding process. This ensures that each panel receives consistent application of adhesive and banding material, significantly reducing material wastage and production errors.

- Multi-Stage Processing: The machine incorporates a comprehensive sequence of operations as depicted in the accompanying flowchart, which includes:

- Pre-Milling: Achieves optimal edge surface preparation by removing surface irregularities, ensuring a smooth, clean finish.

- End Cutting: Precise cutting of panel edges to prepare them for banding.

- Gluing and Pressing: Automated application of adhesive followed by pressing to ensure firm attachment of the edge band.

- Buffing and Scraping: Final touch-up processes that clean and smooth the edges, enhancing the overall appearance and feel of the panels.

- Flexible Configuration: The machine’s modular design allows it to accommodate a variety of panel sizes and shapes, offering flexibility to manufacturers working with custom products.

- High-Speed Operation: Thanks to its high-performance motors and optimized work-cycle algorithms, the machine can handle high-volume production without compromising on quality.

- Safety Measures: Built-in safety protocols, including emergency stop functions and safety guards, ensure a risk-free working environment for operators.

Operational Flow

The pictorial flow diagram highlights the sequence of operations for edge band application. Each stage is crucial to achieving a flawless finish, emphasizing the machine’s ability to execute tasks with precision and reliability.

- Pre-Milling and Separating Agent Application: By accurately preparing the panel edge, these initial stages set the foundation for a high-quality finish.

- Adhesive Application: The gluing station utilizes advanced adhesive technology, ensuring a strong bond between the band and the panel edge. Fast melt adhesives, if used, allow quick curing, which is advantageous in high-speed production scenarios.

- Lamp Baking: Specifically positioned heaters cure the adhesive, ensuring durability and longevity of the edge band.

- Corner Trimming and Scraping: Automated trimming and scraping units perfect the panel edges, creating smooth, visually appealing profiles.

- Buffing and Detergent Application: These finishing steps polish and clean the edges, resulting in excellent aesthetic properties.

Applications and Benefits

The Automatic Servo Control Flexible Edge Banding Machine finds application in various sectors, including furniture manufacturing, cabinetry, and interior design. It’s particularly beneficial for businesses seeking increased production speeds whilst maintaining high-quality standards. The machine’s versatility in handling different edge materials aligns with the growing demand for customized furniture pieces, allowing manufacturers to cater to a wider audience without necessitating large-scale machinery adaptations.

Ease of Use and Maintenance

Operators will appreciate the machine’s intuitive interface and straightforward maintenance procedures. Regular updates and software options are available to ensure the machine remains at peak performance, while modular components facilitate easy replacement and servicing.

Conclusion

The Automatic Servo Control Flexible Edge Banding Machine is a testament to innovation in woodworking technology. Its combination of advanced servo control, comprehensive multi-stage processing capabilities, and the dedication to precision ensures that every panel that passes through emerges as a superior, finished product. By enhancing operational efficiency and delivering consistent quality, this machine becomes an invaluable asset for any manufacturing facility aiming to elevate its production capabilities.

Categories

Automation conneting equipment auxiliary machine Foam machinery Mattress machines Metal processing machine Plywood working machine Solid wood working machineTags