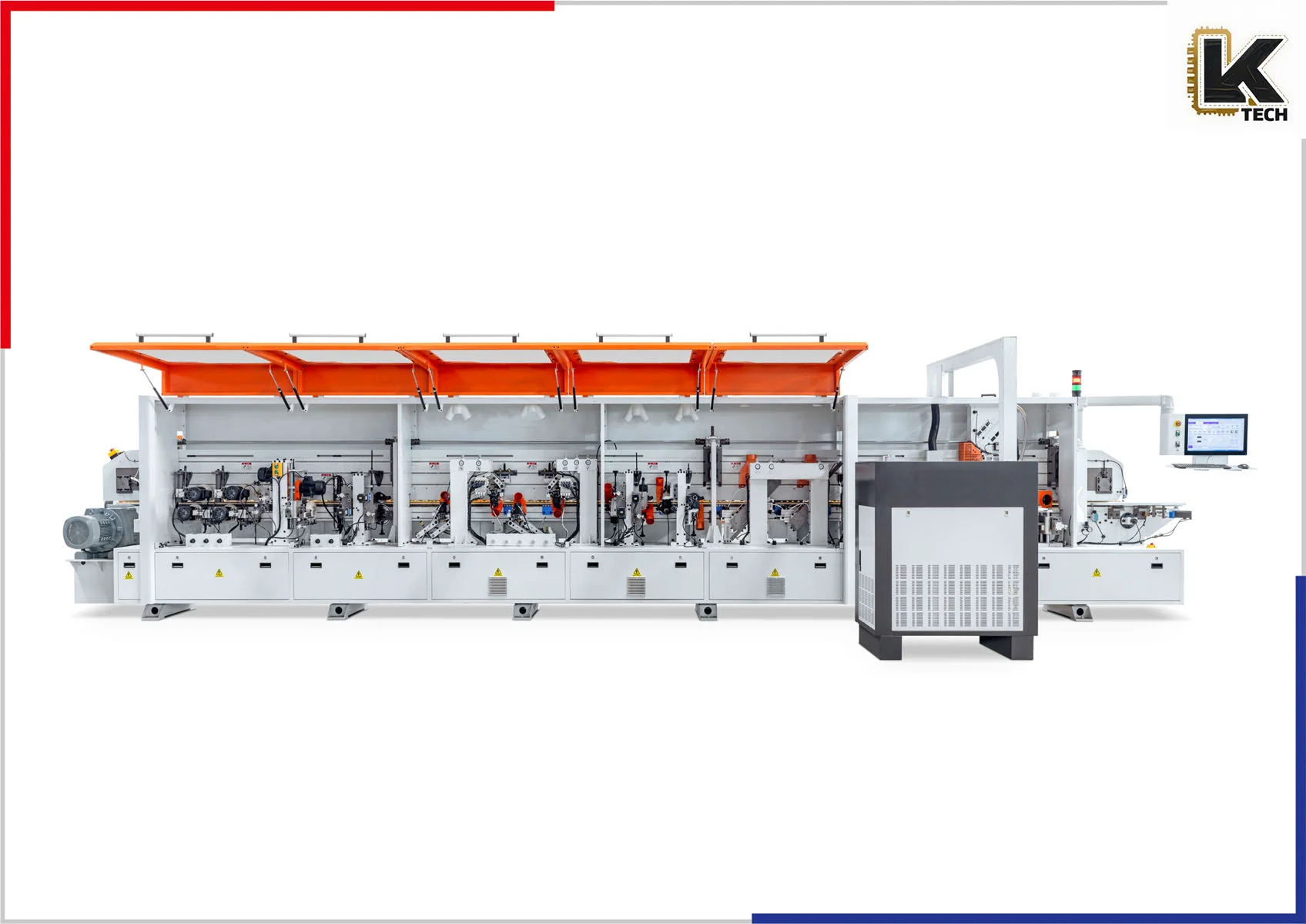

High-Definition Seamless Laser Edge Banding Machine

High-Definition Seamless Laser Edge Banding Machine

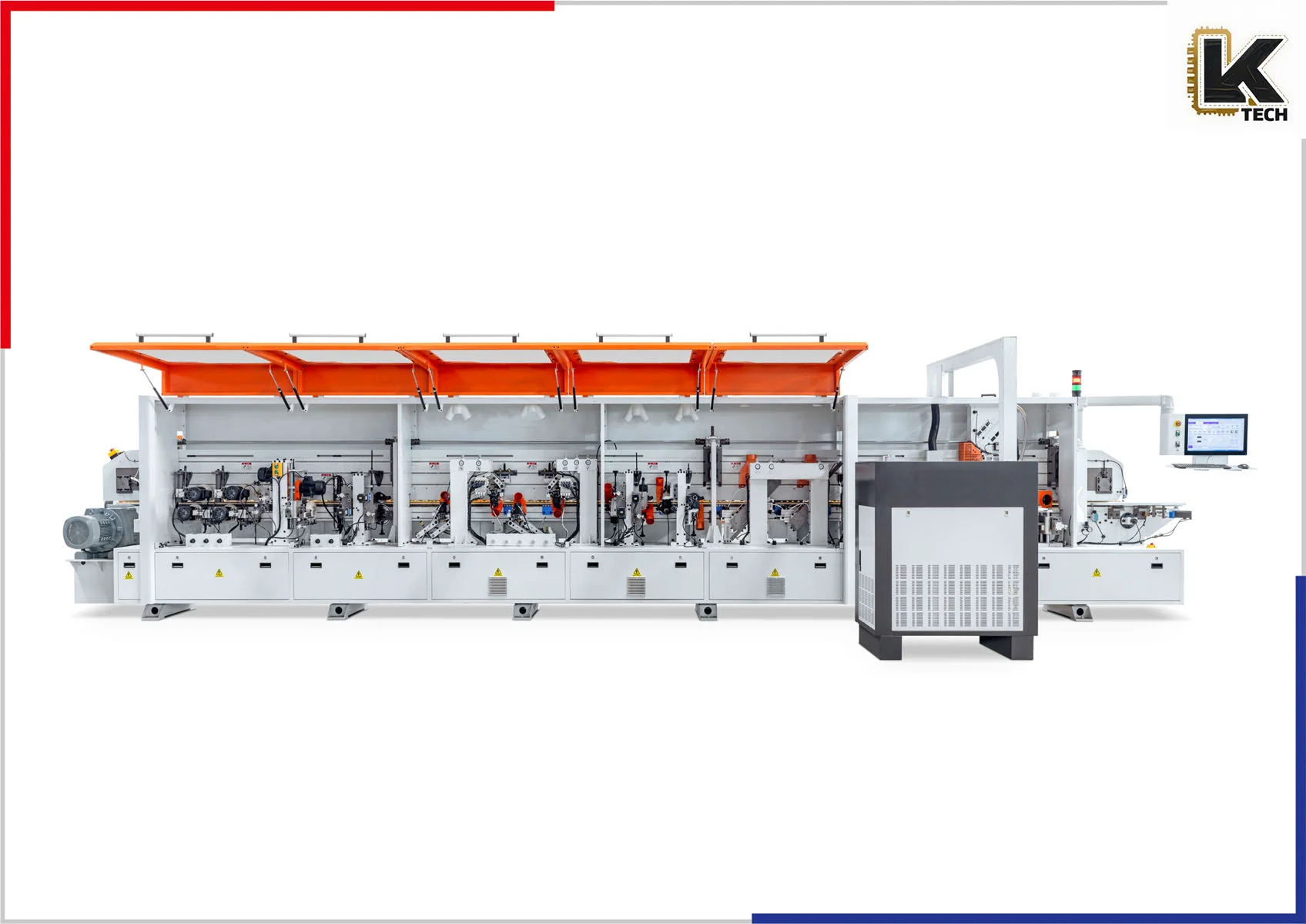

High-Definition Seamless Laser Edge Banding Machine from LK-Tech,a pioneering advancement in woodworking technology designed to elevate precision, efficiency, and streamlined aesthetics in the production of furniture components. This cutting-edge machine exemplifies innovation in edge banding with its seamless integration of advanced laser technology, ensuring the highest standards of finish quality and operational efficiency.

The high-definition laser edge banding machine presents an industrial breakthrough in the world of edge processing, delivering flawless finishes that meet the stringent demands of modern-day woodworking and cabinetry. At the core of its design is the laser bonding technology, which offers unparalleled precision and seamless adhesion of edge materials, eliminating visible glue lines and enhancing the overall aesthetic appeal of the finished product. This process ensures that edges are not only functional but also visually appealing, contributing to overall product quality.

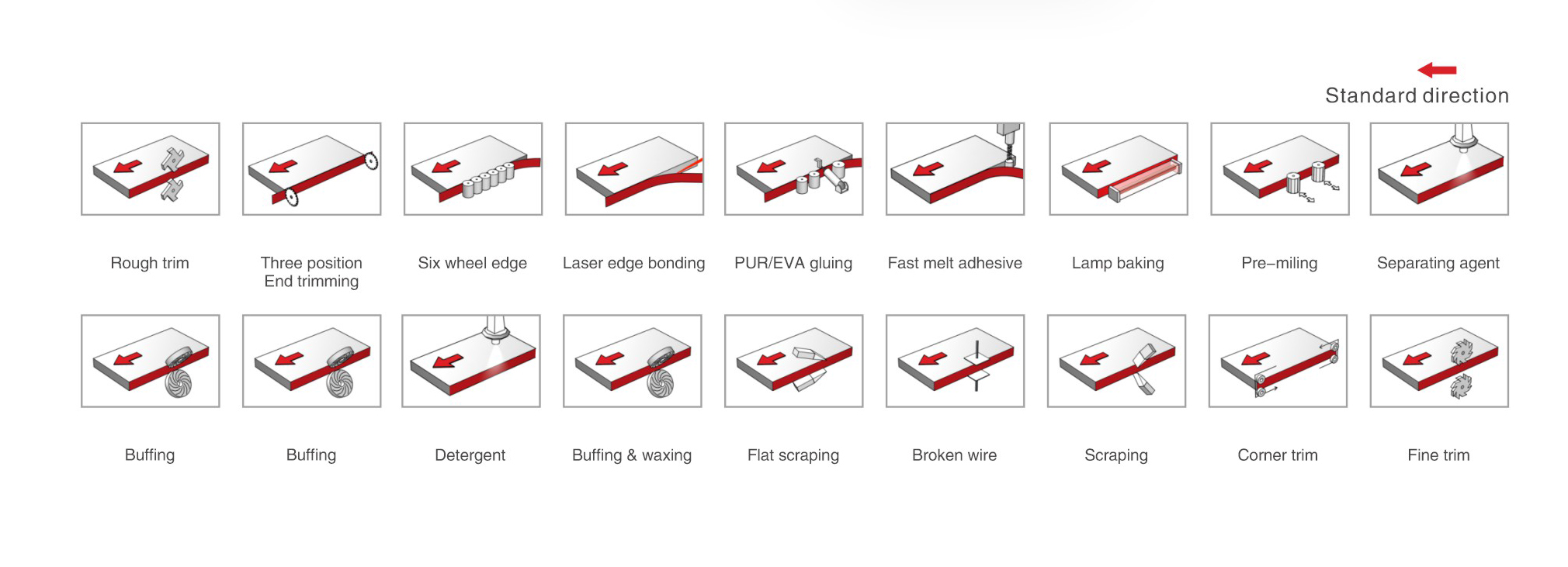

Optimized for performance, this machine is equipped with a complex system of stages, each meticulously designed to perform a specific task in the edge banding process, as illustrated in the operational diagram above. The process begins with rough trimming, efficiently shaping the initial contours of the panel edges with precision and speed. Next, end trimming and six-wheel edging provide multi-dimensional edge processing capabilities, ensuring smooth and uniform edges that align with the exact specifications of each project.

Laser edge bonding marks the centerpiece of this machine’s capabilities. Utilizing state-of-the-art laser technology, it precisely adheres the edge material to the panel, resulting in a seamless and robust attachment that enhances durability and aesthetic value. This eliminates traditional adhesive lines, resulting in a smooth, continuous surface.

To complement the laser edge bonding, the machine incorporates PUR/EVA gluing techniques and fast melt adhesive systems, accommodating various edge banding materials with versatility and efficacy. These features ensure optimal adhesion while maintaining a clean operation environment that is paramount for high-end woodworking production.

Continuing along the operational sequence, lamp baking enhances the adhesion process by providing the necessary heat and curing conditions, ensuring a perfect bond between edge materials and the panel. Pre-milling ensures precise preparation of panels before edge banding, refining the surface to accommodate seamless attachment. To further optimize bonding, the application of a separating agent prevents unwanted adhesion and facilitates effortless processing.

Advanced buffing stages follow, delivering a pristine, polished surface that amplifies the refined aesthetics and tactile experience of the final product. Buffing and waxing contribute to the surface’s sheen and protection, ensuring the panel edges retain their beauty and robustness over time. The integration of detergent application serves to cleanse and prepare surfaces meticulously, enhancing adhesive quality and surface cleanliness.

To address excess material or inconsistencies, flat scraping, broken wire resolution, and scraping stages provide corrective functionalities, maintaining flawless surface conditions. Corner trimming and fine trimming features are meticulously engineered to address intricate corners and fine details, ensuring precision even in the most challenging design geometries.

The machine’s design focuses not only on process quality but also on operational efficiency. Automated control systems allow intricate adjustments and real-time monitoring of the entire process, providing operators with an interface that is as intuitive as it is informative. This ensures minimal downtime and maximum productivity, making it an invaluable asset in large-scale production environments.

Further enhancing user experience, the machine is equipped with advanced safety mechanisms, ensuring operator well-being and safeguarding against potential mishaps. Accessibility and maintenance are optimized to ensure longevity and reliability, with durable components and intuitive design that facilitates easy upkeep.

Overall, the High-Definition Seamless Laser Edge Banding Machine combines cutting-edge technology and robust design to offer exceptional performance and unparalleled quality in edge banding processes. Whether producing cabinets, furniture, or customized paneling, this machine sets new standards in precision, efficiency, and seamless beauty. The commitment to innovation by LK Tech guarantees that every panel processed is not only technically superior but also a visual masterpiece, aligning with the highest standards of professional craftsmanship and design.

Invest in this technology to transform woodworking production, save time, reduce material wastage, and enhance product quality, solidifying your position in competitive markets that demand nothing less than excellence. With this machine, boundaries in design and production are redefined, offering limitless possibilities that meet your unique requirements and innovative aspirations.

Categories

Automation conneting equipment auxiliary machine Foam machinery Mattress machines Metal processing machine Plywood working machine Solid wood working machineTags