Hot Press Machine ITE Series Overview

The Hot Press Machine series, encompassing models ITE120-3, ITE100-1, and ITE400-5, represents a pinnacle of engineering design and manufacturing quality for diverse industrial applications. These robust machines are prime tools in woodworking, material compression, and other industries involving heat application and pressure for crafting and molding products. Their exemplary performance, efficiency, and innovative technology make them essential equipment for enterprises looking to streamline their operations and achieve high-quality outputs.

Key Features and Specifications

-

ITE120-3 Hot Press Machine

- Table Size: 2500mm x 1300mm

- Number of Worktable Layers: 3

- Maximum Pressure: 120 Tons

- Maximum Heating Temperature: 120°C

- Number of Hot Plates: 4

- Cylinder Specification: φ140mm, φ110mm (6 pieces each)

- Cylinder Specifications: 4kW

- Circulation Pump Power: 2.2kW

- Heating Tube Power: 48kW

- Outlook Size: 3700mm x 1600mm x 2250mm

- Net Weight: 8500 kg

The ITE120-3 model is designed for medium-scale enterprises requiring a versatile hot press solution. Its 3-layer capability allows increased production efficiency without sacrificing quality. The heating capacity ensures optimal material processing under controlled conditions, yielding superior adhesion and finish.

-

ITE100-1 Hot Press Machine

- Table Size: 2500mm x 1300mm

- Number of Worktable Layers: 1

- Maximum Pressure: 100 Tons

- Number of Hot Plates: 2

- Cylinder Specification: φ100mm (6 pieces)

- Cylinder Travel: 100mm

- Hydraulic Power: 4kW

- Circulation Pump Power: 2.2kW

- Heating Tube Power: 48kW

- Outlook Size: 3700mm x 1800mm x 2550mm

- Net Weight: 6000 kg

The ITE100-1 is tailored for smaller facilities or those with specific pressure requirements. With only one worktable layer, it is compact yet powerful, making it an excellent choice for projects requiring precision and high-quality surface finishes. Its moderate weight and footprint allow it to fit into various settings without dominating space.

-

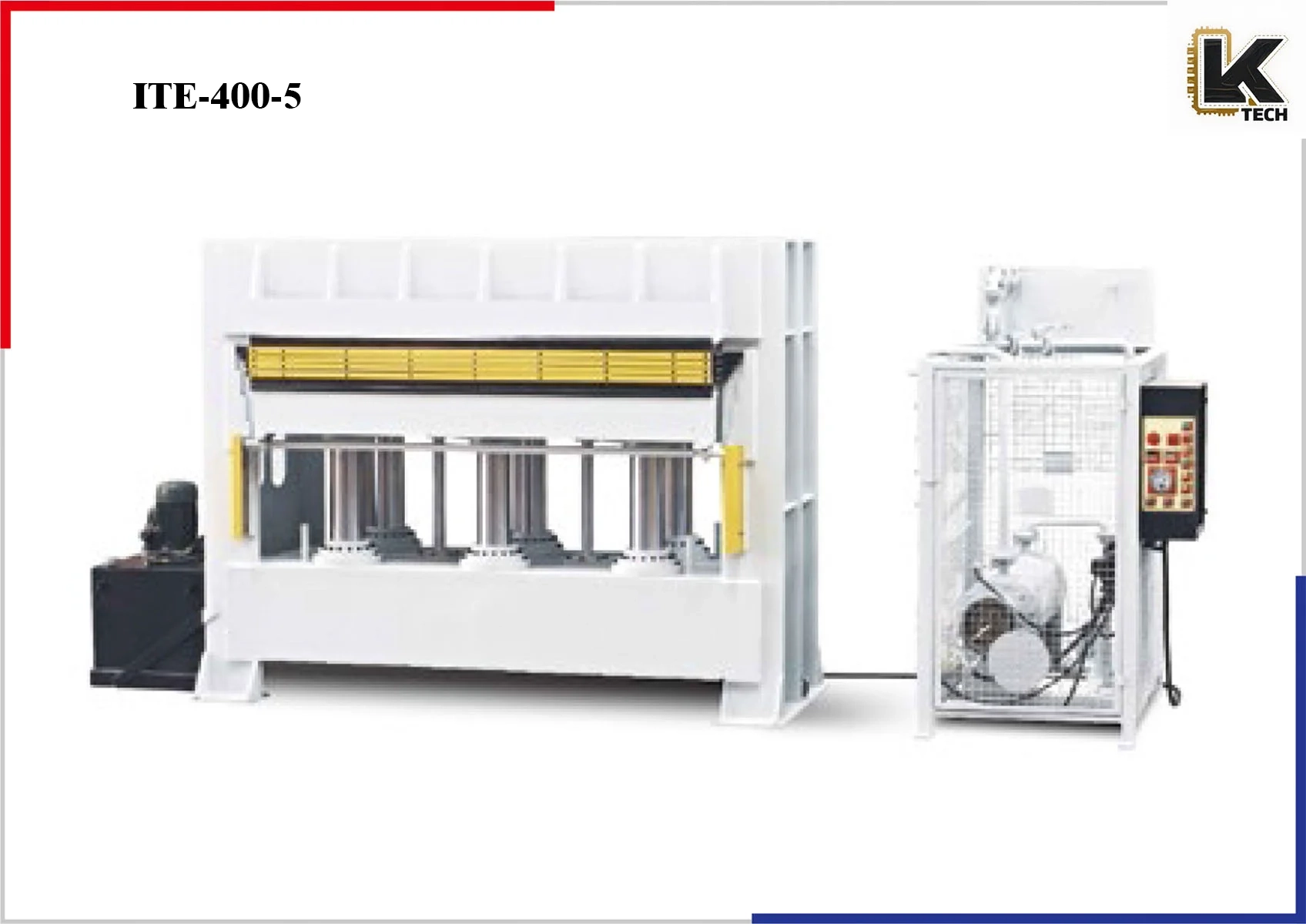

ITE400-5 Hot Press Machine

- Table Size: 2700mm x 1350mm

- Number of Worktable Layers: 5

- Maximum Pressure: 400 Tons

- Number of Hot Plates: 6

- Cylinder Specification: φ245mm, φ200mm, φ140mm (6 pieces each)

- Cylinder Travel: 550mm

- Hydraulic Power: 7.5kW

- Circulation Pump Power: 2.2kW

- Heating Tube Power: 96kW

- Outlook Size: 4200mm x 1800mm x 4000mm

- Net Weight: 18000 kg

The ITE400-5 is the heavyweight champion of the series, capable of handling substantial workloads with its 5-layer structure. Perfect for industrial settings, it ensures optimal hot press operations that can accommodate multiple materials at once, maximizing throughput. This machine offers robust construction and superior pressure capabilities, suited for the most demanding applications.

Applications

The Hot Press Machine ITE series is versatile and can be effectively utilized in multiple sectors such as:

- Woodworking: Ideal for laminating, bonding veneers, and creating engineered wood products.

- Composite Manufacturing: Efficiently integrates different materials, applying heat and pressure for enhanced performance.

- Ceramics and Plastics: Assists in molding shapes and finishing surfaces with perfection.

- Metalworking: Suitable for sintering and shaping metal parts, offering robust performance under high pressure.

Key Advantages

- High Efficiency: Increased productivity due to the fast heating and pressing cycles. The hot press machines significantly reduce production time while maintaining the quality of the end product.

- Precision Control: Designed for accurate temperature and pressure control, ensuring that every job meets specified standards.

- Robust Build Quality: Engineered with high-quality materials, ensuring long-term reliability and low maintenance costs.

- User-Friendly Interface: Equipped with intuitive control systems that allow operators to manage the processes easily, reducing training time and increasing overall safety.

Conclusion

Choosing the right hot press machine is critical for any business involved in manufacturing and material processing. The ITE Series provides compelling options for varying operational needs, from small-scale applications to large industrial processes. Coupled with their advanced technical features, reliability, and diverse applications, investing in the ITE hot press machines guarantees an enhancement in quality and efficiency, positioning your enterprise for success.

Entering a competitive market means having the right tools at your disposal, and with the ITE hot press machines, you’re equipped for superior performance, productivity, and profitability. Experience the cutting-edge technology and manufacturing excellence that the ITE series brings to your operations. Whether you are looking to streamline production capabilities or enhance product quality, the ITE hot press machinery is your go-to solution.

Categories

Automation conneting equipment auxiliary machine Foam machinery Mattress machines Metal processing machine Plywood working machine Solid wood working machineTags