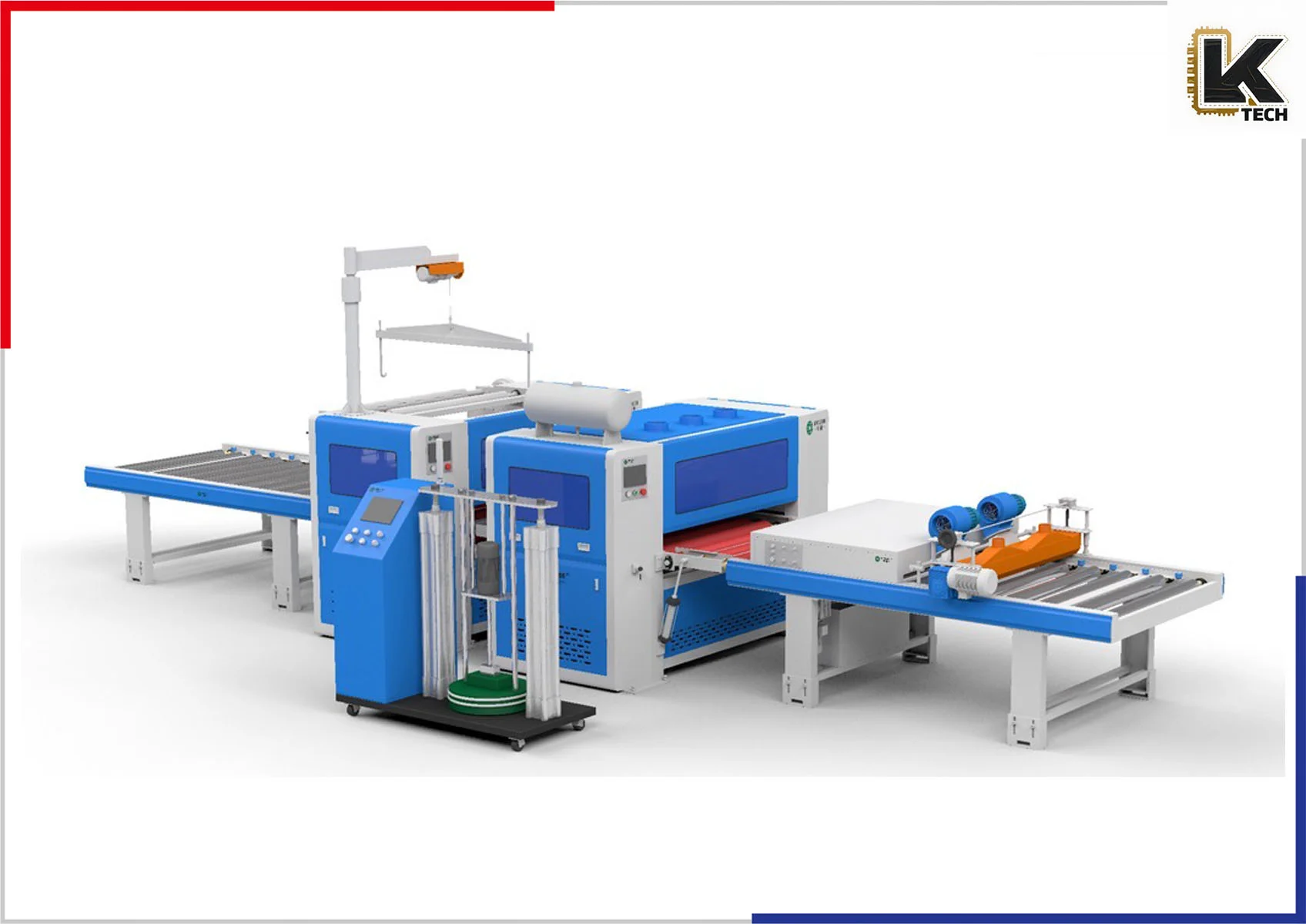

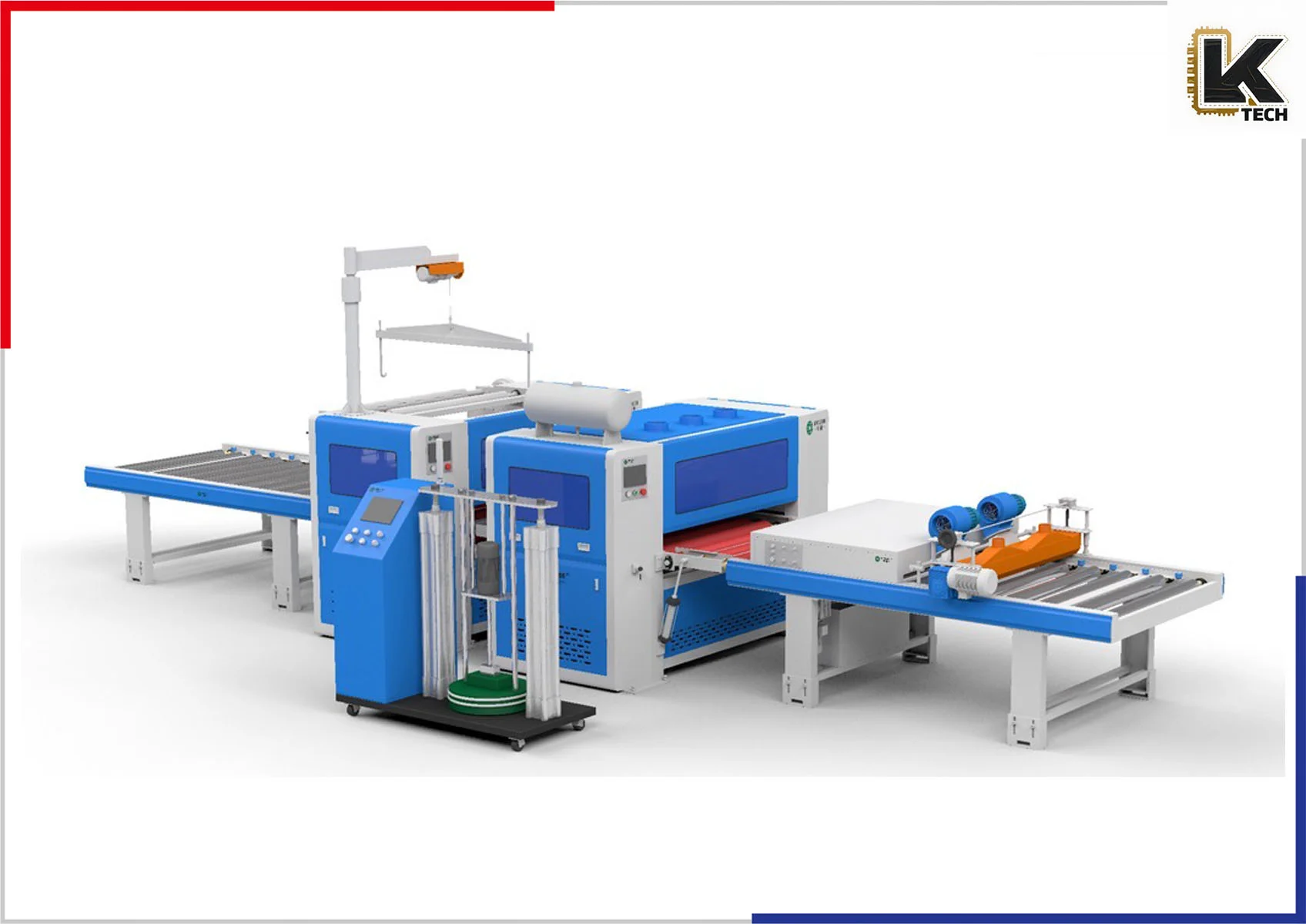

Comprehensive Overview of the ITE-PT1400-PUR Flat Laminating Production Line

Introduction

In the realm of advanced manufacturing, precision machinery plays a pivotal role in ensuring optimal production processes. The ITE-PT1400-PUR Flat Laminating Production Line stands out as a state-of-the-art solution designed to meet the increasing demands in the wood, furniture, and paneling industries. With its advanced features, efficient workflow, and user-friendly control system, this machine is poised to enhance production quality while maximizing throughput.

Key Specifications

The ITE-PT1400-PUR boasts impressive specifications that cater to a variety of industrial requirements:

- Maximum Board Width: 1250 mm

- Plate Thickness Range: 3-50 mm, offering flexibility for various materials

- Working Speed: Adjustable between 3 to 18 meters/minute, ensuring fast output yet adhering to quality

- Control Method: PLC (Programmable Logic Controller) for streamlined automation and control

- Dust Removal System: Integrated to maintain a clean working environment

- Oven Conveyor System: A built-in feature for drying and curing processes

- Spreader: Ensures uniform application of PUR adhesive

- Melt System: Optimizes the melting of adhesives for consistent performance

- Fitting Machine (single roll): Facilitates easy application of edging materials

- Protection Membrane Device: Adds an extra layer of durability to your products

- Edge Repair Device: Ensures precision final adjustments to edges

- Conveyor Size: 2.89 m x 1.64 m x 0.94 m

- Machine Size: 10.2 m x 2.64 m x 2.95 m

Design and Build Quality

The ITE-PT1400-PUR is designed with a robust construction that ensures longevity and reliability in industrial environments. The machine’s body is built from high-quality materials that resist wear and tear, even under heavy usage.

- Ergonomic Design: The machine features an ergonomic design that facilitates easy access to all components for maintenance and operation.

- Efficient Layout: The compact yet highly functional layout maximizes space without compromising on performance.

Operating Principle

The operation of the ITE-PT1400-PUR utilizes an advanced layering process to achieve high-quality lamination. The workflow begins with the feeding of raw boards into the machine, which are then passed through the following stages:

- Surface Preparation: The boards are initially cleaned using the integrated dust removal system, ensuring all surfaces are free from debris for optimal adhesion.

- Adhesive Application: The spreader uniformly applies the PUR (Polyurethane Reactive) glue, ensuring consistent coverage across the entire surface area.

- Heating and Melting: The melt system activates, aiding in the adhesion of the PUR glue. The precise application of heat ensures that the adhesive reaches the optimal temperature for bonding.

- Lamination Process: As the boards travel along the conveyor, they pass through the oven conveyor which helps cure the adhesive, thus providing a strong bond between layers.

- Fitting and Edging: Once laminated, the boards are then guided to the fitting machine where edges can be applied for a finished look. The edge repair device ensures all edges are polished and uniform.

- Quality Check and Output: The final boards are inspected for quality and uniformity before being outputted for packaging or further processing.

User-friendly Control

One of the standout features of the ITE-PT1400-PUR is its advanced PLC control system:

- Intuitive Interface: The control panel is user-friendly, allowing operators to set speed, temperature, and other parameters with ease.

- Real-time Monitoring: Operators can monitor various metrics and machine performance in real-time, ensuring any issues are promptly addressed to minimize downtime.

- Automated Controls: The PLC system automates many tasks, reducing the need for manual interventions and improving overall efficiency.

Environmental Considerations

Manufacturing sustainability is a growing concern, and the ITE-PT1400-PUR is designed with eco-friendly practices in mind:

- Energy Efficiency: The machine operates at optimal energy consumption levels, reducing the carbon footprint associated with production.

- Safety Features: Equipped with safety sensors and emergency stop buttons, the ITE-PT1400-PUR ensures operator safety while minimizing potential hazards during operation.

- Dust Removal and Ventilation: The integrated dust removal system improves air quality in the workplace, creating a healthier environment for operators.

Applications

The ITE-PT1400-PUR Flat Laminating Production Line is versatile, catering to a myriad of applications including:

- Furniture Manufacturing: Ideal for lamination of furniture components, ensuring durability and aesthetic appeal.

- Interior Design: Excellent for sequential applications in paneling and wall installation projects.

- Building Materials Production: Applicable in constructing durable and aesthetically pleasing building materials that conform to modern standards.

Conclusion

Investing in the ITE-PT1400-PUR Flat Laminating Production Line is a strategic decision geared towards enhancing productivity and ensuring superior manufacturing quality. With its impressive specifications, efficient workflow, and user-friendly controls, it stands as a beacon of modern technology in the realm of flat lamination.

This advanced production line not only meets the expectations of today’s manufacturing demands but also sets the industry standard for future innovations. Whether in furniture, interior design, or building materials, the ITE-PT1400-PUR is sure to deliver exceptional results that exceed customer expectations.

Experience the transformation of your production processes with the unparalleled efficiency and reliability of the ITE-PT1400-PUR Flat Laminating Production Line. Elevate your manufacturing capabilities and achieve premium quality results with this state-of-the-art solution.

Categories

Automation conneting equipment auxiliary machine Foam machinery Mattress machines Metal processing machine Plywood working machine Solid wood working machineTags