ITE-5110 / ITE-5110T Spindle Moulder

ITE-5110 / ITE-5110T Spindle Moulder

Introduction

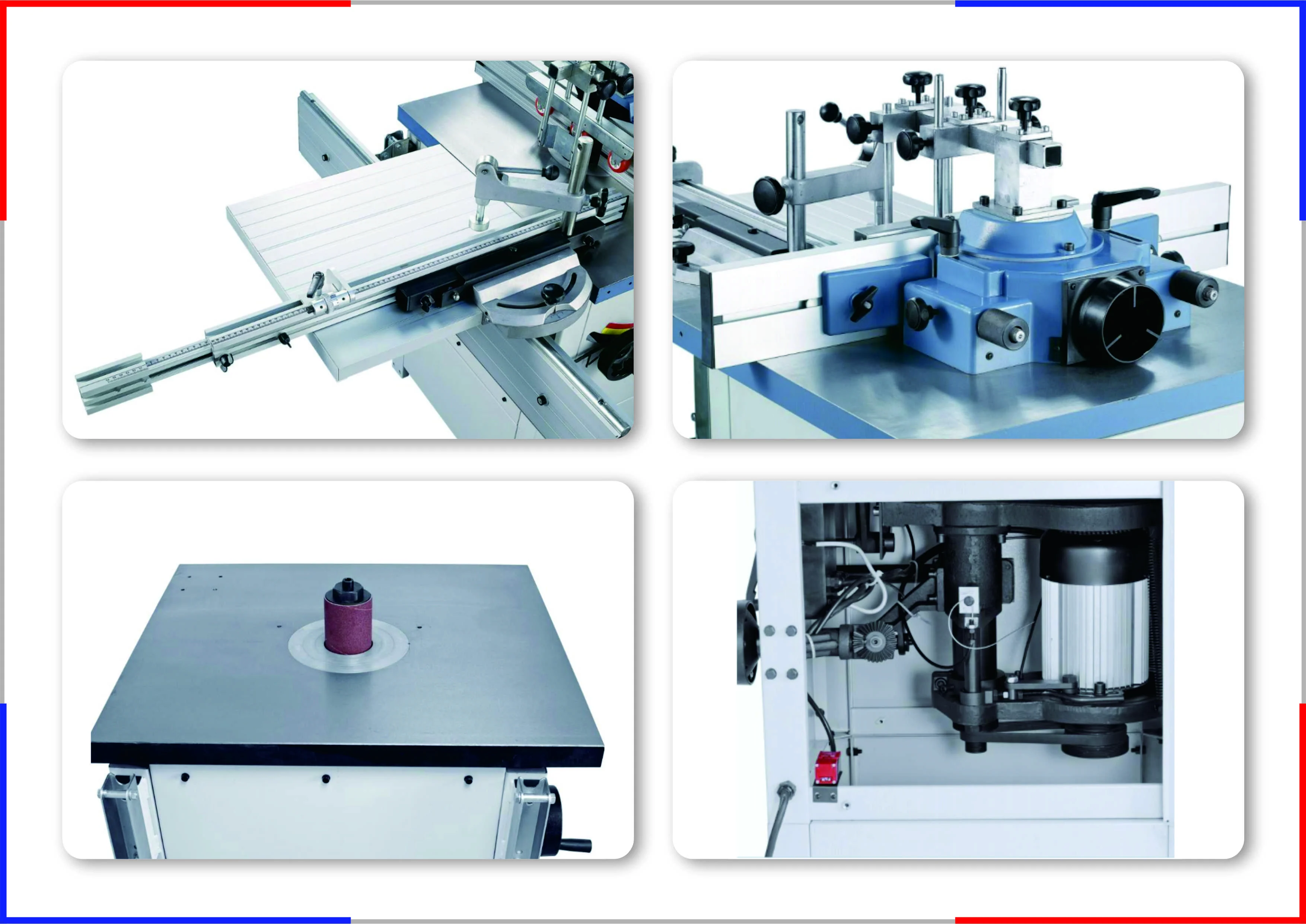

For woodworking professionals and enthusiasts alike, the spindle moulder stands as a pillar of versatility and precision. Designed specifically for crafting and shaping wood into various forms, the ITE-5110 and ITE-5110T models emphasize performance, functionality, and user comfort. Combining robust engineering with innovative design, these machines offer solutions for both amateur crafters and seasoned experts in the woodworking industry.

Overview

The ITE-5110 and ITE-5110T spindle moulders are equipped with a powerful 2800W motor, ensuring that every project can be handled with ease. These machines are designed to take on various moulding tasks, providing significant flexibility and adaptability with adjustable spindle speeds and tilting capabilities. Both models feature a sliding table, allowing for smooth material handling and enhanced production efficiency. With user-friendly controls, precision tolerances, and advanced safety features, the ITE-5110 and ITE-5110T take woodworking to the next level.

Key Features

1. Powerful Motor and Performance

At the heart of both the ITE-5110 and ITE-5110T is an impressive 2800W powered motor. This level of input power translates into a machine that can handle a variety of workloads without compromising performance. The spindle rotation speeds range from 1800 RPM to 9000 RPM, allowing users to select the optimum speed for their specific application, whether it’s sanding, cutting, or intricate moulding.

2. Precision Engineering

The ITE spindle moulders feature precision-engineered components with exceptional accuracy. The table dimensions for ITE-5110 are 480 mm x 690 mm, while the ITE-5110T boasts a slightly larger table at 710 mm x 640 mm, perfect for larger workpieces. The height of the tables is ergonomically designed at 900 mm, promoting comfortable use.

3. Sturdy Spindle Design

Both models come with a robust spindle diameter of 30 mm and a travel of 100 mm, allowing for versatility in the types of cuts and shapes that can be achieved. The spindles can also be tilted from -10° to +30°, providing an added layer of functionality for angled cuts and grooves.

4. Innovative Sliding Table

The inclusion of a sliding table system with dimensions of 500 mm x 480 mm enhances the machine’s capabilities. Users can easily guide their workpiece smoothly and accurately across the table, ensuring precision with every pass. The length of the sliding table rail, measuring 1200 mm, is designed to accommodate longer workpieces, increasing the likelihood of successful moulding operations.

5. User-Friendly Control Panel

Both the ITE-5110 and ITE-5110T feature an intuitive control panel designed for ease of use. Key controls include an emergency stop button for added safety, variable speed settings, and straightforward controls for adjusting the spindle height and tilt. These features cater to users of all skill levels, from hobbyist woodworkers to industry professionals.

Technical Specifications

- Model: ITE-5110 / ITE-5110T

- Rated Input Power: 2800W

- Table Size:

- ITE-5110: 480 mm x 690 mm

- ITE-5110T: 710 mm x 640 mm

- Table Height: 900 mm

- Spindle Diameter: 30 mm

- Spindle Travel: 100 mm

- Tool Opening: 200 mm

- Spindle Speed:

- 9000 RPM

- 6000 RPM

- 3000 RPM

- 1800 RPM

- Sliding Table Size: 500 mm x 480 mm

- Length of Sliding Table Rail: 1200 mm

- Packing Size:

- ITE-5110: 725 mm x 525 mm x 690 mm

- ITE-5110T: 760 mm x 690 mm x 700 mm

Additional Features

- Sanding Capability: Both models can be utilized as sanders at 1800 RPM, providing even more breadth in functionality for users focused on finishing surfaces.

- Workpiece Roller Feeder: Ensures a stable and smooth feeding of materials through the machine, reducing the manual burden on the operator and enhancing safety.

- Durability and Reliability: Constructed with high-quality materials, the ITE spindle moulders are built to withstand rigorous use while maintaining exceptional precision.

Safety Considerations

Safety is paramount when operating woodworking machinery. The ITE-5110 and ITE-5110T models come equipped with a variety of safety features:

- Emergency Stop Button: Easily accessible for immediate shut-off.

- Protective Guards: Enclose moving parts to prevent accidents during operation.

- Stable Base for Reduced Vibration: To ensure precision cuts without unnecessary movement.

It’s essential for users to follow all operational guidelines, wear appropriate protective gear, and regularly maintain the machine for optimal safety and efficacy.

Conclusion

In the woodworking world, the ITE-5110 and ITE-5110T spindle moulders offer combinations of power, precision, and versatility. These machines are engineered to meet the demands of both novice woodworkers and seasoned professionals, standing out as a must-have in any workshop. With a design that prioritizes user comfort and operational efficiency, investing in either the ITE-5110 or ITE-5110T ensures that your crafting experience will be enhanced, streamlined, and above all, productive.

Whether you’re shaping custom furniture, creating intricate moldings, or sanding surfaces to perfection, the ITE spindle moulders deliver exceptional results time and time again. Embrace the possibilities with the power of an ITE spindle moulder – where every cut counts.

Categories

Automation conneting equipment auxiliary machine Foam machinery Mattress machines Metal processing machine Plywood working machine Solid wood working machineTags