Standard Surface Sander: The Ultimate Solution for Precision Sanding

Introduction

In the world of woodworking, precision and efficiency are paramount. The Standard Surface Sander stands out as a leading choice for both professionals and craftspeople who seek to enhance their woodworking projects with unparalleled smoothness and finish. With its advanced engineering, robust construction, and user-friendly features, this surface sander offers an exceptional sanding solution that elevates work quality and efficiency. This comprehensive product description delves into the features, advantages, applications, and specifications of the Standard Surface Sander, demonstrating why it is an indispensable tool in any woodworking shop.

Design and Construction

Robust Build Quality

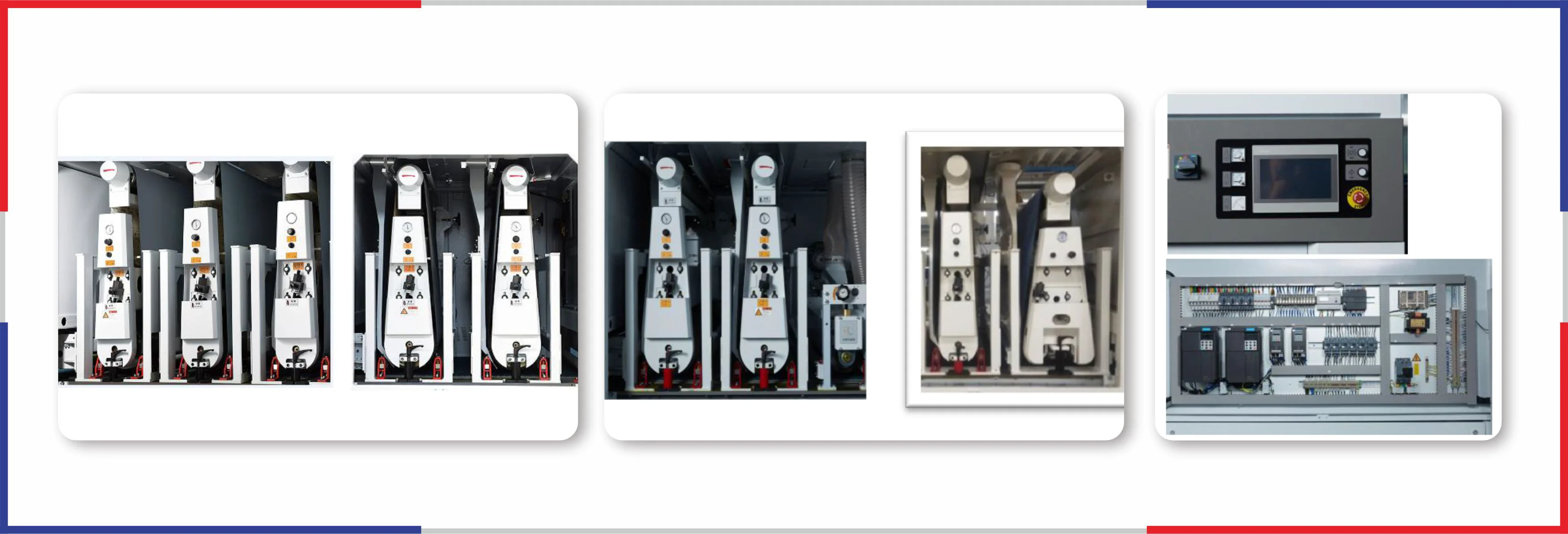

The Standard Surface Sander features a solid, heavy-duty design that can withstand the rigors of industrial use. Constructed with premium materials, its sturdy casing ensures longevity and durability. The sander’s frame is designed for stability during operation, minimizing vibration and enhancing the quality of the sanding process.

Compact Footprint

Despite its robust build, the Standard Surface Sander maintains a relatively compact size, making it suitable for varying workshop sizes. Its design allows for easy installation in smaller spaces without compromising its efficient performance.

Aesthetic and Functional Design

The sleek and modern aesthetic of the machine further complements its functionality. The combination of a white, gray, and red color scheme not only looks appealing but also serves a practical purpose. Bright colors are utilized strategically to indicate operational areas, ensuring that users can operate the machine safely from the start.

Operational Features

Advanced Sanding System

Equipped with a high-performance sanding system, the Standard Surface Sander delivers consistent sanding results across a variety of materials including hardwoods, softwoods, and composites. Its sanding mechanism is designed to handle materials of varying thicknesses, making it an ideal choice for diverse woodworking tasks.

Variable Speed Control

The capacity to adjust the sanding speed is a standout feature of the Standard Surface Sander. Users can set the speed according to their specific material requirements, allowing for optimal sanding performance. This versatility contributes to achieving the desired surface finish without over-sanding or damaging the workpiece.

User-Friendly Control Panel

The integrated control panel boasts a user-friendly interface that simplifies operation. With clear indicators and controls, operators can easily adjust settings such as speed, power, and dust collection. Moreover, the digital display provides real-time feedback, making it easier to monitor the sanding process and make necessary adjustments on the fly.

Efficient Dust Collection System

Dust management is an essential aspect of woodworking, and the Standard Surface Sander is equipped with a sophisticated dust collection system. This feature captures wood dust and debris during the sanding operation, promoting a cleaner workspace and enhancing the visibility of the work area. Not only does this contribute to a healthier work environment, but it also improves the machine’s longevity by keeping internal components free from dust accumulation.

Performance and Efficiency

Precise Sanding Capability

The Standard Surface Sander is engineered for precision, enabling users to achieve a perfectly smooth surface every time. Its specialized sanding belts and efficient mechanism ensure consistent material removal, resulting in a flawless finish that meets the highest standards of craftsmanship.

Time-Saving Operation

Time is a valuable resource in any workshop, and the Standard Surface Sander excels in efficiency. With its advanced features, operators can complete sanding tasks in less time compared to traditional sanding methods. The ability to adjust speeds and maintain stability during operation ensures an effective sanding process, which ultimately leads to increased productivity.

Versatility in Applications

The versatility of the Standard Surface Sander makes it suitable for a wide range of applications. Whether you are working with solid wood, plywood, or composite materials, this sander can accommodate various wood types and thicknesses. Thus, it is an ideal tool for furniture makers, cabinet manufacturers, and any woodworkers aiming for professional results.

Benefits for Users

Enhanced Finish Quality

One of the most significant benefits of the Standard Surface Sander is the enhanced finish quality it delivers. By consistently providing smooth surfaces, the sander minimizes the amount of manual finishing work required afterward, ultimately saving time and effort in the finishing process.

Reduced Labor Costs

For professional woodworking shops, the efficiency and quality of the Standard Surface Sander can translate to lower labor costs. By streamlining the sanding process and integrating mechanisms that produce superior results, businesses can increase output and reduce the need for skilled labor.

Safety Features

Safety is a top priority when operating woodworking machinery, and the Standard Surface Sander makes no compromises in this aspect. The design includes safety guards and emergency stop features, ensuring that operators can work with confidence and minimize the risk of accidents.

Maintenance and Durability

Low Maintenance Requirements

The Standard Surface Sander is designed for minimal maintenance. Its robust construction minimizes wear and tear, and regular inspections are made easy with accessible components. Users can perform routine maintenance without extensive training or complexity, ensuring the machine remains in optimal working condition without significant downtime.

Long-Service Life

Durability is a hallmark of the Standard Surface Sander. Engineered for heavy-duty use, this machine promises a long service life, providing value for investment over time. Many users report years of satisfaction with their Standard Surface Sander, making it a wise choice for long-term operations.

Technical Specifications

| No. | Item | WT RR700 | WT RRC700 |

|---|---|---|---|

| 1 | Max. Work Width (mm) | 700 | 700 |

| 2 | Min. Work Length (mm) | 260 | 390 |

| 3 | Working Thickness (mm) | 3-150 | 3-150 |

| 4 | Unit Diameter (mm) | Φ190/Φ190 | Φ190/Φ190/Φ120+pad |

| 5 | Unit Shore Hardness | Steel/80Sh | Steel/80Sh/55Sh |

| 6 | Air Pressure (MPa) | 0.6 | 0.6 |

| 7 | Abrasive Belt Size (mm) | 730×1900 | 730×1900 |

| 8 | Feeding Speed (m/min) | 5-20 | 5-20 |

| 9 | Total Power (kW) | 22 | 37 |

| 10 | Overall Dimensions (mm) | 1580×2240×2220-2370 | 1580×2700×2220-2370 |

| 11 | Platform Height (mm) | 900 | 900 |

| 12 | Net Weight (kg) | 2100 | 2700 |

| 13 | Voltage | 380V/50Hz/3PH | 380V/50Hz/3PH |

| No. | Item | WT RRR1300 | WT RR1300 | WT RRC1300 | WT RC1300 |

|---|---|---|---|---|---|

| 1 | Max. Work Width (mm) | 1300 | 1300 | 1300 | 1300 |

| 2 | Min. Work Length (mm) | 280 | 280 | 490 | 490 |

| 3 | Working Thickness (mm) | 3-150 | 3-150 | 3-150 | 3-150 |

| 4 | Unit Diameter (mm) | Φ240/Φ240/Φ240 | Φ240/Φ240 | Φ240/Φ240/Φ170+pad | Φ240/Φ170+pad |

| 5 | Unit Shore Hardness | Steel/80Sh/55Sh | Steel/80Sh | Steel/80Sh/55Sh | Steel/80Sh |

| 6 | Air Pressure (MPa) | 0.6 | 0.6 | 0.6 | 0.6 |

| 7 | Abrasive Belt Size (mm) | 1350×2620 | 1350×2620 | 1350×2620 | 1350×2620 |

| 8 | Feeding Speed (m/min) | 5-30 | 5-30 | 5-30 | 5-30 |

| 9 | Total Power (kW) | 84 | 65 | 84 | 61 |

| 10 | Overall Dimensions (mm) | 2235×3050×2450-2600 | 2235×2700×2450-2600 | 2235×3050×2450-2600 | 2235×2700×2450-2600 |

| 11 | Platform Height (mm) | 900 | 900 | 900 | 900 |

| 12 | Net Weight (kg) | 5700 | 4600 | 5700 | 4600 |

| 13 | Voltage | 380V/50Hz/3PH | 380V/50Hz/3PH | 380V/50Hz/3PH | 380V/50Hz/3PH |

Conclusion

The Standard Surface Sander is not just another tool; it’s an investment in precision, efficiency, and craftsmanship that every woodworking professional should consider. With its superior design, comprehensive features, and unparalleled performance, it sets the benchmark for what a surface sander should offer. Whether you’re looking to enhance your workshop’s productivity, streamline your operations, or achieve the finest finish on your woodworking projects, the Standard Surface Sander is the ultimate solution that stands ready to meet your needs.

Elevate your woodworking today with the Standard Surface Sander – where innovation meets craftsmanship!

This product description paints a comprehensive picture of the Standard Surface Sander, aiming to inform potential buyers about its benefits and features while also establishing a strong case for its utility in various woodworking applications.

Categories

Automation conneting equipment auxiliary machine Foam machinery Mattress machines Metal processing machine Plywood working machine Solid wood working machineTags